Time: 2024-09-05 01:50:48 Source: Luoyang Monton Bearing Science & Technology Co.,ltd.

Angular contact ball bearings and deep groove ball bearings are two common types of rolling bearings, each with unique characteristics and application scenarios. Today, the editor will make a detailed comparison between the two in terms of structural characteristics, load-bearing capacity, usage scenarios, installation and maintenance, etc., to help you better understand and choose.

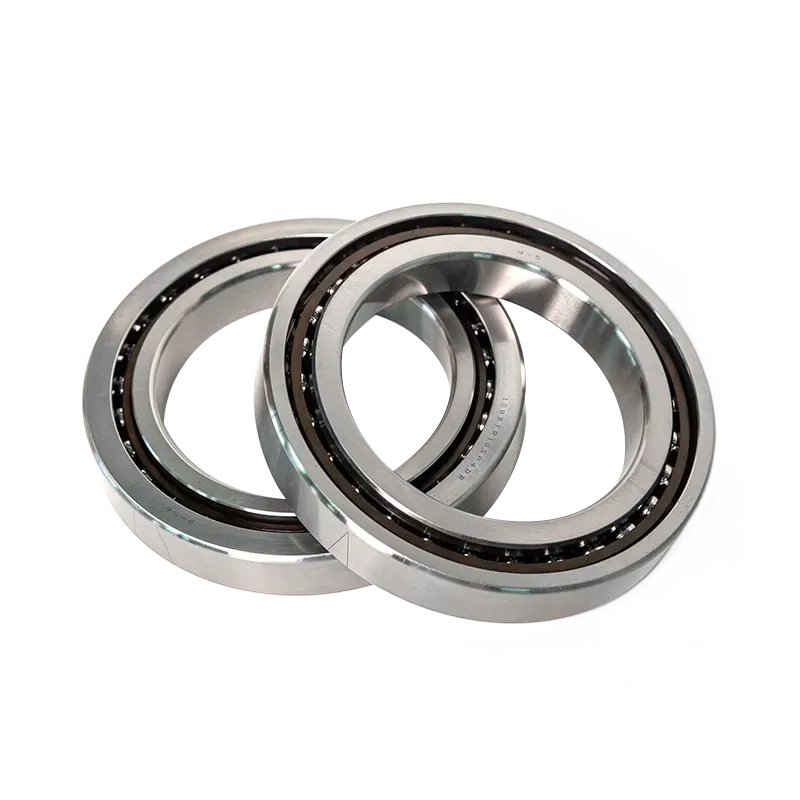

Angular contact ball bearings

Angular contact ball bearings are mainly composed of an inner ring, an outer ring, a steel ball and a cage. Its notable feature is the contact angle between the ring and the ball. The standard contact angles are usually 15°, 25° and 40°. This design enables angular contact ball bearings to bear both radial and axial loads, and the axial load-bearing capacity increases as the contact angle increases. In addition, the manufacturing process of angular contact ball bearings is strict and the accuracy level is high, which can meet the operation needs of various high-precision mechanical equipment.

Deep groove ball bearings

Deep groove ball bearings are the most common type of rolling bearings. Their structural features include the deep groove between the inner and outer rings and the raceway between the rolling elements (usually spheres). This design makes deep groove ball bearings excellent at carrying radial loads and can also bear axial loads to a certain extent. However, the axial load carrying capacity of deep groove ball bearings is weaker compared to angular contact ball bearings.

Angular contact ball bearings

Angular contact ball bearings have strong load-carrying capacity, especially axial load-carrying capacity, thanks to their unique contact angle design. As the contact angle increases, the axial load capacity of the bearing also increases. In addition, angular contact ball bearings also have good anti-friction performance and high precision, which enables them to work stably under heavy loads and high-speed rotation conditions.

Deep groove ball bearings

Deep groove ball bearings have relatively small load-carrying capacity and mainly bear radial loads, while also bearing certain axial loads. However, when only bearing radial loads, their contact angle is zero and their axial load-carrying capacity is limited. When deep groove ball bearings have a large radial clearance, their performance may be close to that of angular contact ball bearings, but overall they are still not as good as angular contact ball bearings in terms of axial load-carrying.

Angular contact ball bearings

Angular contact ball bearings are widely used in various high-precision, high-speed and heavy-load mechanical equipment due to their high precision, high speed and high load capacity. For example, in key parts such as machine tool spindles, motors, and transmission devices, angular contact ball bearings can significantly improve the accuracy and stability of the equipment. In addition, in the fields of automobiles, ships, aviation and other fields, angular contact ball bearings also play an important role and are used in key parts such as drive axles, steering gears, braking systems, propulsion systems, steering gears, and stabilizers.

Deep groove ball bearings

Deep groove ball bearings are widely used in various occasions that need to bear radial loads due to their simple structure, convenient installation and maintenance, and low cost. For example, deep groove ball bearings are used in the rotor shafts of motors and generators, bicycle hubs, seat posts and pedals, automobile transmission systems, engines, wheels and gearboxes, and in the rotating parts of household appliances. plays an important role.

Install

Whether it is an angular contact ball bearing or a deep groove ball bearing, you need to pay attention to the following points during installation: ensure the cleanliness of the bearing seat and shaft; choose the appropriate lubrication method and lubricant; install the bearing fasteners correctly; avoid The raceways and rolling elements of the bearing are damaged during installation.

Maintenance

The maintenance of angular contact ball bearings and deep groove ball bearings mainly includes regular inspection of the operating status of the bearings, timely replacement of severely worn bearings, and keeping the bearings clean and lubricated. In addition, for angular contact ball bearings that need to bear large axial loads, special attention needs to be paid to the accuracy of their axial positioning to avoid bearing damage caused by improper installation.

Angular contact ball bearings and deep groove ball bearings have obvious differences in structural characteristics, load-bearing capacity, usage scenarios, installation and maintenance. When selecting, comprehensive considerations should be made based on specific application scenarios and needs to ensure that the selected bearings can meet the operating requirements of the equipment and have a good service life.