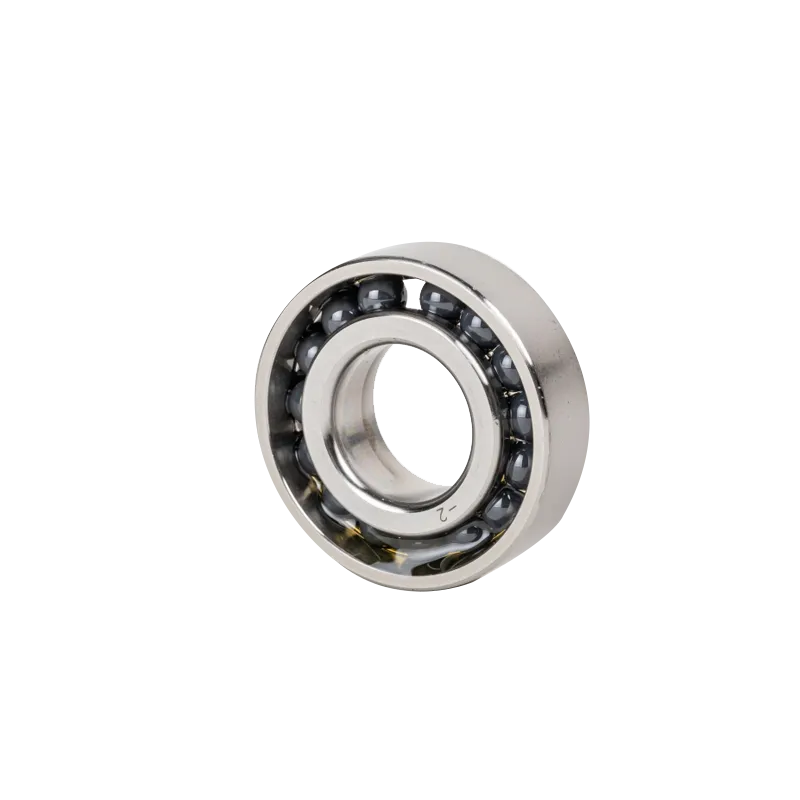

Non magnetic steel bearing is a special type of bearing used in non-magnetic or weak magnetic environments. Its core material is non-magnetic steel (non-magnetic steel), which has the characteristics of anti magnetic interference, corrosion resistance, high strength and toughness. It is mainly used in situations that are sensitive to magnetic fields or need to avoid magnetic field interference.

View Details

Aerospace is an emerging industry. With the advancement of aircraft engine design, the increase in energy transmission and speed, the continuous improvement of power, the continuous increase in thrust ratio and power-to-weight ratio, the aviation bearing material is required to have high temperature resistance of 350-500℃, high surface hardness, high wear resistance, good fracture toughness, impact toughness and excellent corrosion resistance. High nitrogen stainless bearing steel can meet the application environment requirements in the fields of aviation, aerospace, nuclear-powered aircraft engine main bearings, rocket fuel pump bearings, and nuclear-powered drive mechanisms.

View Details

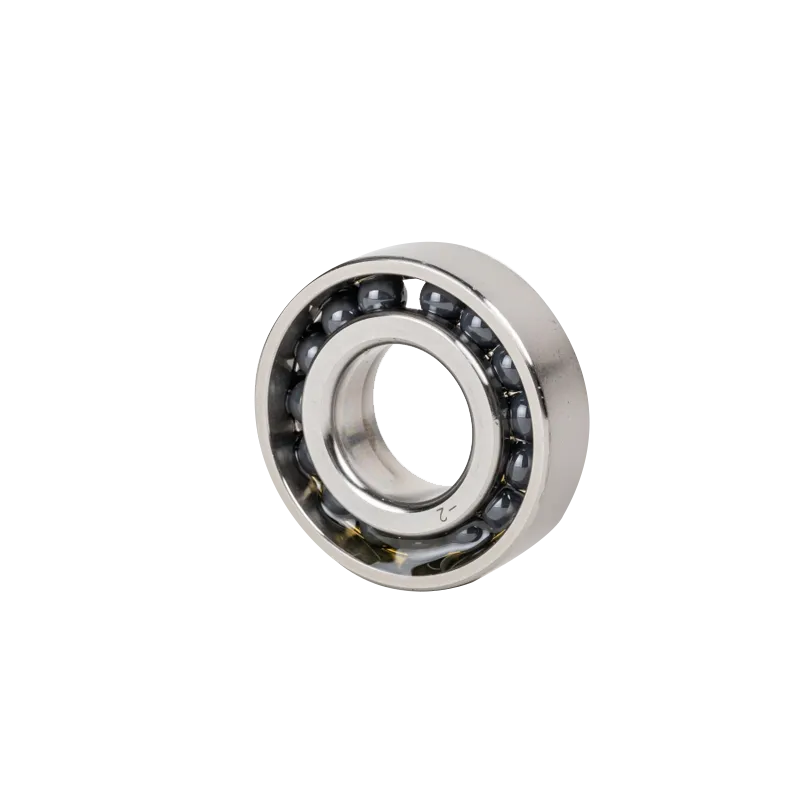

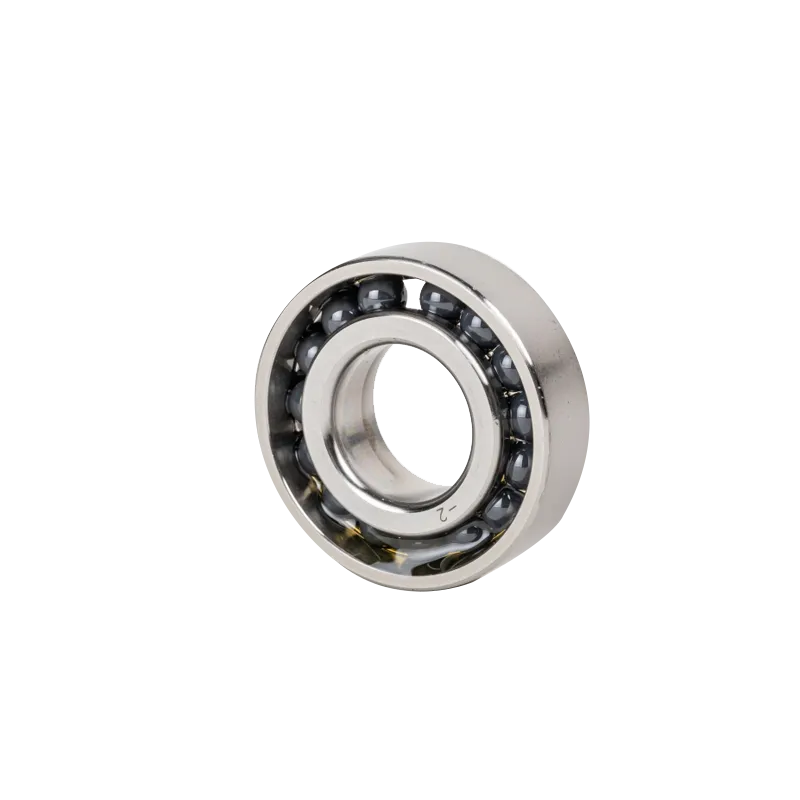

Monton can provide high-quality bearings for turbojets that can withstand high temperatures, high speeds and complex loads. The main type of bearings used in turbojets is angular contact ball bearings, which are mainly used to withstand other torques. Their structural characteristics enable them to withstand radial and axial loads at the same time. In turbojets, this type of bearing is often used in positions that need to support rotating parts and withstand axial thrust at the same time. In order to improve wear resistance and high temperature resistance, angular contact ball bearings are often made of ceramic materials, such as ceramic ball bearings. For small gas turbine engines (such as micro turbojets), due to their extremely high operating speeds (up to 60,000 to 150,000 r/m), the performance requirements for bearings are more stringent.

View Details

Navigation platform bearings can be divided into navigation platform bearings for ships, navigation platform bearings for rockets and navigation platform bearings for missiles. Bearings are required to have long life (more than 10 years), high precision, high reliability, corrosion resistance, and withstand certain vibration and impact loads. When the bearing works under low speed or swing conditions, the working or storage temperature is -40℃~+80℃.

View Details

High temperature and high speed bearings are resistant to high temperatures up to 300℃, ball bearings have a maximum speed of 60,000 r/min, cylindrical roller bearings have a maximum speed of 50,000 r/min, oil injection lubrication, high Dm·n value, and good dimensional stability at high temperatures. They are mainly used in gas turbine engines and other occasions with the highest requirements.

View Details

This type bearings have the properties of corrosion resistance, high temperature resistance, strong radiation resistance, wear resistance, and non-magnetic properties, and can work in strong magnetic fields. It is mainly used in instruments, nuclear reactors and high-sensitivity guidance systems. The non-magnetic materials used in bearings are mainly: 0Cr40Ni55AI3, Cr23Ni28M05T3AIV (G52# alloy), GH05 alloy, etc.

View Details