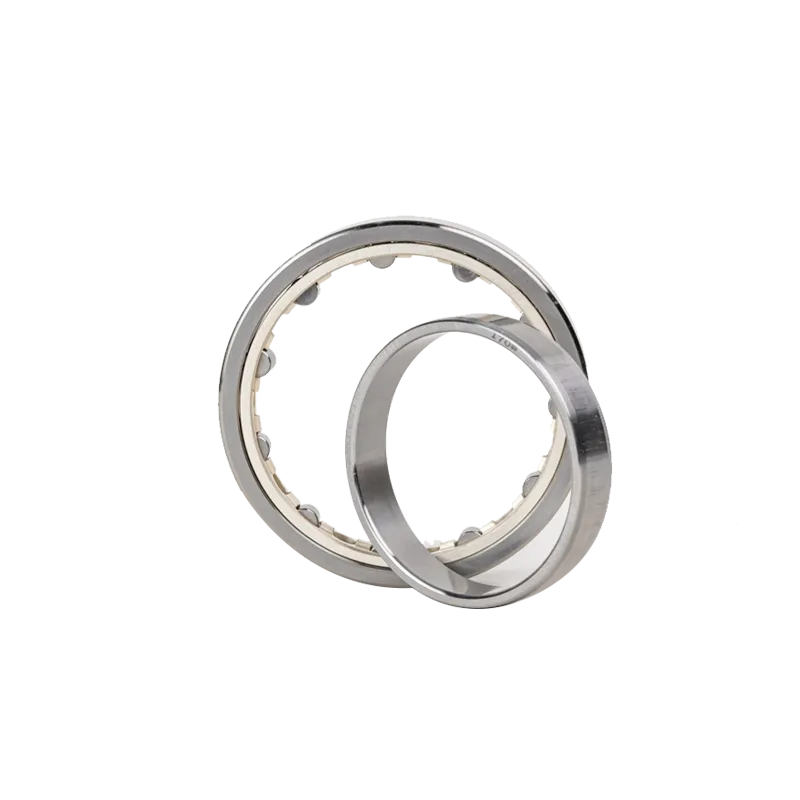

Aerospace precision bearings are used in a variety of aerospace applications, including aircraft engines, landing gear systems, control systems and other key components. Engine bearings are roughly divided into two categories of use; main shafts and reduction gears (auxiliary transmission systems). The design and manufacture of major products requires high technology for shaft bearings used in high-speed and high-speed temperature conditions.

Aerospace bearings require bearings to be high-precision, high-strength, low-friction, stable and reliable.

For example, main shaft bearings for turboshaft engines used in helicopter engines, transmissions and aircraft, and transmission bearings that transmit power to the main rotor and tail rotor. The drive mechanism of satellite solar cells provides bearings that operate stably in harsh environments, requiring bearings with high reliability, high vacuum, radiation and a wide temperature range. The bearings of the rotating shaft of the turbopump used in rocket turbopump engines are required to operate stably in ultra-high-speed cryogenic liquid fuel environments such as liquid hydrogen (−253°C) and liquid oxygen (−183°C). Our company improves the reliability of bearing design through simulated dynamic design. Our company provides highly reliable bearing technology to contribute to the development of the aerospace industry.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing data and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products and creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.