Special bearings for medical devices mainly include high-temperature magnetron bearings, high-speed dental drill bearings, high-speed grinding drill bearings, etc.

High-temperature magnetron bearings are mainly used for high-power high-speed rotating anode X-ray electron tubes. The environmental characteristics of their use are: vacuum (1x10-6Pa), high temperature (maximum ambient temperature 550℃), and solid lubrication. Bearing materials generally use high-temperature resistant materials such as Cr13Mo4V and Cr4Mo4V.

High-speed dental drill bearings are mainly used for turbine assemblies for dental drill handpieces. The characteristics of their use environment are: 0.25mPa air pressure, high speed (350,000 to 400,000 rpm), low noise (below 70 decibels), and dripping oil lubrication.

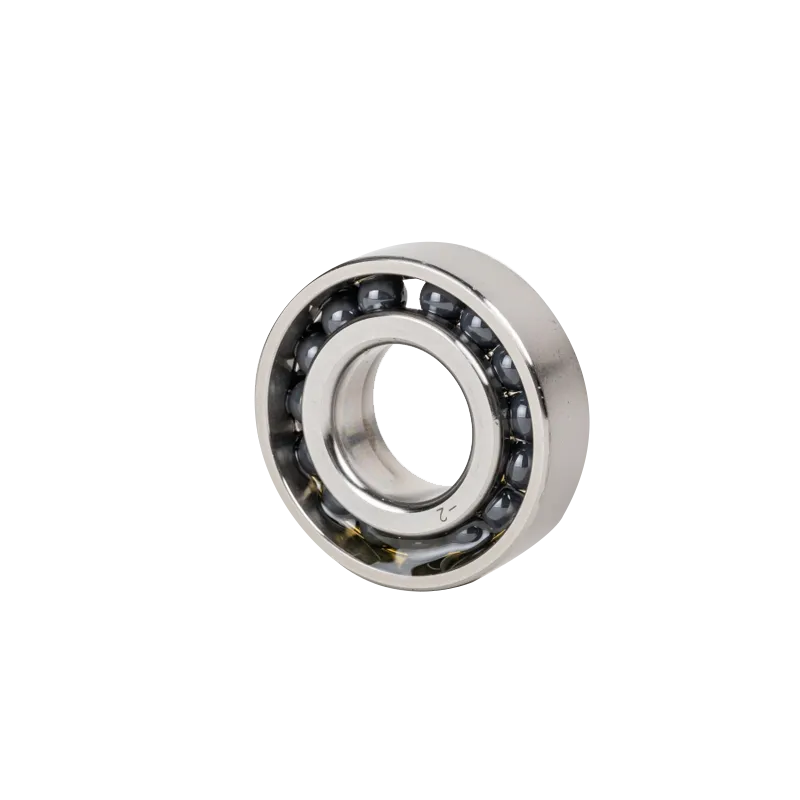

High-speed grinding drill bearings are mainly used for handheld high-speed grinding drill assemblies. The characteristics of their use environment are: low noise (below 60 decibels), operating room environment (physiological saline, human body fluids, blood), high speed (5000 to 100,000 rpm), and spray lubrication. High-temperature magnetron bearings generally have two structures: deep groove ball bearings and full ball without cages. Lubrication generally uses special high-temperature grease with molybdenum disulfide or polytetrafluoroethylene particles added to the grease. Special lubrication methods such as silver plating on the surface of the bearing and cage or coating on the surface of the bearing can also be used. High-speed dental drill and high-speed grinding drill bearings generally have a single-sided or double-sided deep groove ball with dust cover structure, and lubrication generally uses edible oil lubrication or spray lubrication.

Our company can develop special high-temperature magnetron bearings of various sizes and structures below 550℃ and speed below 10,000rpm, as well as high-speed dental drill and high-speed grinding drill bearings of various sizes and structures below 400,000 rpm.