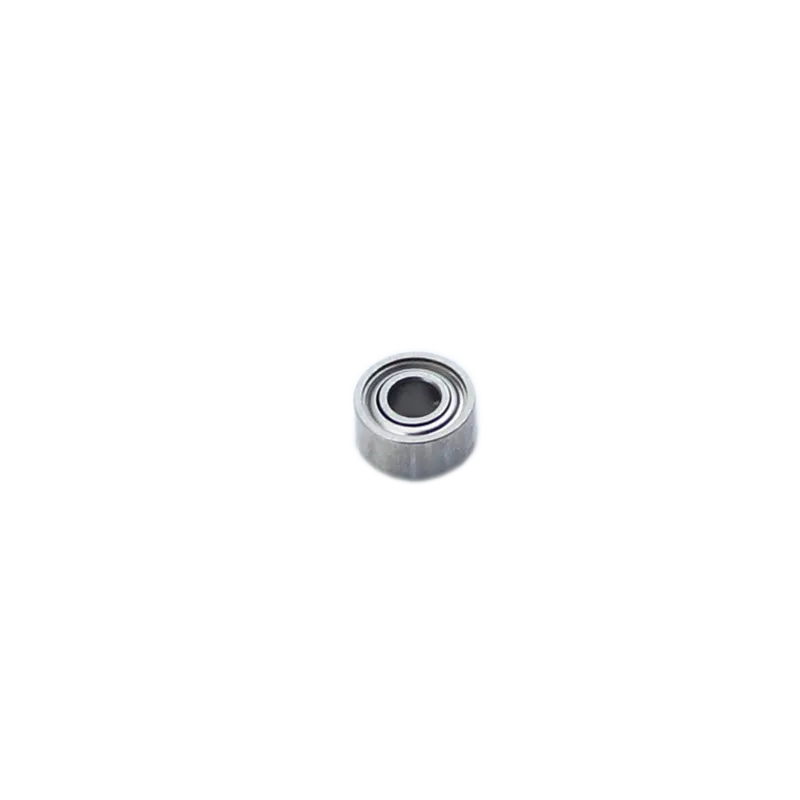

Non magnetic steel bearing is a special type of bearing used in non-magnetic or weak magnetic environments. Its core material is non-magnetic steel (non-magnetic steel), which has the characteristics of anti magnetic interference, corrosion resistance, high strength and toughness. It is mainly used in situations that are sensitive to magnetic fields or need to avoid magnetic field interference.

High strength and wear resistance: Non magnetic steel materials typically have high mechanical strength and wear resistance.

Non magnetic steel achieves non-magnetic or low magnetic properties by adding a large amount of alloying elements such as nickel, manganese, chromium, copper, etc. to the steel to lower the austenite transformation point below room temperature. According to the composition of steel, non-magnetic steel can be divided into high Ni steel, high Mn steel, high Cr Ni steel, high Cr-Mn-N steel, etc; According to their performance, non-magnetic steel can be divided into austenitic non-magnetic stainless steel and non-magnetic structural steel. In order to ensure the stability of austenite, sufficient amounts of Ni and Mn must be added to the former. At the same time, to ensure stainless performance, the mass fraction of Cr in the steel should be at least 13%. Non magnetic structural steels are mostly made of Fe Mn series non-magnetic steels, which mainly utilize high Mn and C contents to obtain austenitic structures at room temperature, including Fe Mn, Fe Mn Cr, and Fe Mn Al series non-magnetic structural steels.

304N austenitic stainless steel, low permeability medical device and electronic equipment casing.

Energy sector: Bearings for nuclear reactor cooling pumps, corrosion-resistant and non-magnetic.