Turbojet bearings are main components that support rotating components such as compressors and turbine rotors in turbojet engines, and their performance directly determines the reliability, efficiency, and lifespan of the engine.During the development of many turbojet engines, standard size bearings were used. Since bearings play a vital role, their accuracy and durability are key to ensuring that turbojet engines continue at the lowest cost.

Hence, we spent a lot of time developing high-precision ceramic hybrid bearings. Proposed an all-ceramic bearing solution suitable for most types of gas turbines. We can now provide a full set of (without cage/with cage) ceramic bearing solutions. The bearings our company provides for the turbojet engine market are ABEC 7 precision ( Also known as P4 level) and has competitive advantages in quality and price! Use Si3N4 (silicon nitride) ceramic balls as it is best suited for high speed, long durability applications. Bearings with these ceramic balls significantly increase component life through optimized improvements that reduce bearing weight and reduce the inertia of the ceramic balls. This ceramic-on-ceramic system also significantly resists the rolling of hard particles into the raceways. Turbojet engines There are various types of bearings used in turbojet engines, including angular contact ball bearings, fully floating bearings, thrust bearings, air bearings and anti-friction bearings. These bearings have high requirements in terms of material selection, design and manufacturing to ensure that the turbojet engine can operate stably and achieve optimal performance under complex working conditions.

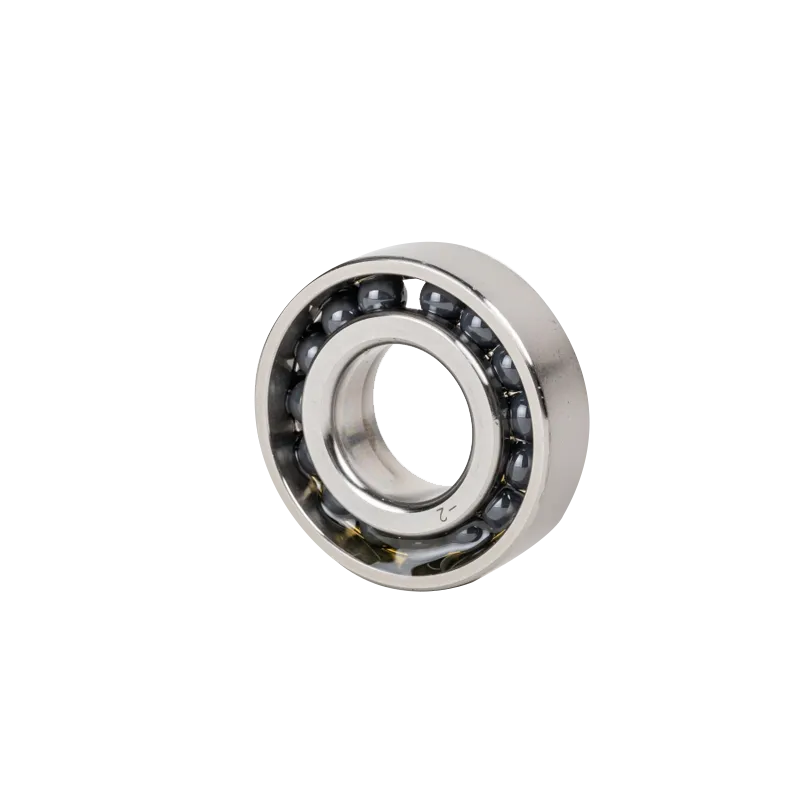

MONTON normal Turbojet bearing:

Bearing

d

D

B

Brand

MTSV7000

10

26

8

MONTON

MTSV708

8

22

7

MONTON

MTSV788

8

16

6

MONTON

MTSV7001

12

28

8

MONTON

MTSV7002

15

32

9

MONTON

MTSV71904

20

37

9

MONTON

796V/P4 HV3 HQ1

6

15

5

MONTON

786V/P4 HV3 HQ1

6

13

3.5

MONTON

797V/P4 HV3 HQ1

7

17

5

MONTON

787V/P4 HV3 HQ1

7

14

3.5

MONTON

798V/P4 HV3 HQ1

8

19

6

MONTON

788V/P4 HV3 HQ1

8

16

4

MONTON

708V/P4 HV3 HQ1

8

22

7

MONTON

799V/P4 HV3 HQ1

9

20

6

MONTON

789V/P4 HV3 HQ1

9

17

4

MONTON

709V/P4 HV3 HQ1

9

24

7

MONTON

7900V/P4 HV3 HQ1

10

22

6

MONTON

7000V/P4 HV3 HQ1

10

26

8

MONTON

7200V/P4 HV3 HQ1

10

30

9

MONTON

7901V/P4 HV3 HQ1

12

24

6

MONTON

7001V/P4 HV3 HQ1

12

28

8

MONTON

7201V/P4 HV3 HQ1

12

32

10

MONTON

7902V/P4 HV3 HQ1

15

28

7

MONTON

7002V/P4 HV3 HQ1

15

32

9

MONTON

7202V/P4 HV3 HQ1

15

35

11

MONTON

7903V/P4 HV3 HQ1

17

30

7

MONTON

7003V/P4 HV3 HQ1

17

35

10

MONTON

7203V/P4 HV3 HQ1

17

40

12

MONTON

7904V/P4 HV3 HQ1

20

37

9

MONTON

7004V/P4 HV3 HQ1

20

42

12

MONTON

7204V/P4 HV3 HQ1

20

47

14

MONTON

7905V/P4 HV3 HQ1

25

42

9

MONTON

7005V/P4 HV3 HQ1

25

47

12

MONTON

A7000 TPFK 2730

10

26

8

MONTON

A7000 TPFK 273T

10

26

8

MONTON

CX B7000VTPFK 273

10

26

8

MONTON

7202 TPFK 108

15

35

11

MONTON

7202 TPFK 109

15

35

11

MONTON

C 7202VTPFK 109

15

35

11

MONTON

A7202 TPFK 415

15

35

11

MONTON

XA7202 TPFK 415

15

35

11

MONTON

A7203 TPFK 374

17

40

12

MONTON

A7304CEMA P4C8OM TPF 82

20

52

15

MONTON

7304LATPFK 118

20

52

15

MONTON

A7305CEMAP4C8OM TPF 82

25

62

17

MONTON

7305LATPFK 118

25

62

17

MONTON

7305X2LATPFK 118

25.2

62

17

MONTON

A730GCEMA P4C8OM TPF 82

30

72

19

MONTON

7306LATPFK 118

30

72

19

MONTON

7306 TPFK-11-3

30

72

19

MONTON

A7308CEMAP4C8OM TPF 82

40

90

23

MONTON

7308LATPFK 118

40

90

23

MONTON

7309 TPFK-11-3

40

100

25

MONTON

7309 TPFK 169

40

1002

5

MONTON

7310 TPFK 169

50

110

27

MONTON

7312 TPFK 169

60

130

31

MONTON

SV7900C TA

10

22

6

MONTON

HYQ SV7900C TA

10

22

6

MONTON

SV7900 AC TA

10

22

6

MONTON

HYQ SV7900 AC TA

10

22

6

MONTON

SV7900C 2VZ TA

10

22

6

MONTON

HYQ SV7900C 2VZ TA

10

22

6

MONTON

SV7900 AC 2VZ TA

10

22

6

MONTON

HYQ SV7900AC 2VZ TA

10

22

6

MONTON

SV7000 C TA

10

26

8

MONTON

HYQ SV7000 C TA

10

26

8

MONTON

SV7000 AC TA

10

26

8

MONTON

HYQ SV7000 AC TA

10

26

8

MONTON

SV7000 C 2VZ TA

10

26

8

MONTON

HYQ SV7000 C 2VZ TA

10

26

8

MONTON

SV7000 AC 2VZ TA

10

26

8

MONTON

HYQ SV7000 AC 2VZ TA

10

26

8

MONTON

SV7200 C TA

10

30

9

MONTON

HYQ SV7200 C TA

10

30

9

MONTON

SV7200 AC TA

10

30

9

MONTON

HYQ SV7200 AC TA

10

30

9

MONTON

SV7200 C 2VZ TA

10

30

9

MONTON

HYQ SV7200 C 2VZ TA

10

30

9

MONTON

SV7200 AC 2VZ TA

10

30

9

MONTON

HYQ SV7200 AC 2VZ TA

10

30

9

MONTON

SV7701 C TA

12

18

3

MONTON

HYQ SV7701 C TA

12

18

3

MONTON

SV7701 AC TA

12

18

3

MONTON

HYQ SV7701 AC TA

12

18

3

MONTON

SV7801 C TA

12

21

5

MONTON

HYQ SV7801 C TA

12

21

5

MONTON

SV7801 AC TA

12

21

5

MONTON

HYQ SV7801 AC TA

12

21

5

MONTON

SV7801 C 2VZ TA

12

21

5

MONTON

HYQ SV7801 C 2VZ TA

12

21

5

MONTON

SV7801 AC 2VZ TA

12

21

5

MONTON

HYQ SV7801 AC 2VZ TA

12

21

5

MONTON

Customized bearing available

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technology training on precision bearing information, installation and use. Perfect pre-sales, in-sales and after-sales services form a guarantee system for high-quality services, providing users with reliable quality bearing products and creating excellent user experience and generous benefits for every customer.

If you have any questions about products and services, please contact the company service department directly.