|

Designation |

Dimensions |

Basic Loading |

Limiting Speed |

Weight |

||||

|

Dynamic |

Static |

nG Greas |

nG Oil |

|||||

|

d |

D |

B |

Cr |

C0r |

Grease |

Oil |

m |

|

|

mm |

mm |

mm |

kN |

kN |

min |

min |

kg |

|

|

B706-C-T-P4S |

6 |

17 |

6 |

2.36 |

0.97 |

110000 |

170000 |

0.005 |

|

B706-E-T-P4S |

6 |

17 |

6 |

2.28 |

0.93 |

95000 |

150000 |

0.005 |

|

B707-C-T-P4S |

7 |

19 |

6 |

2.6 |

1.14 |

95000 |

150000 |

0.008 |

|

B707-E-T-P4S |

7 |

19 |

6 |

2.5 |

1.1 |

85000 |

130000 |

0.008 |

|

B708-C-T-P4S |

8 |

22 |

7 |

3.8 |

1.73 |

80000 |

130000 |

0.01 |

|

B708-E-T-P4S |

8 |

22 |

7 |

3.75 |

1.66 |

75000 |

110000 |

0.01 |

|

B709-C-T-P4S |

9 |

24 |

7 |

5.2 |

2.4 |

75000 |

110000 |

0.015 |

|

B709-E-T-P4S |

9 |

24 |

7 |

5.1 |

2.32 |

67000 |

100000 |

0.015 |

|

B7000-C-T-P4S |

10 |

26 |

8 |

4.25 |

2.08 |

67000 |

100000 |

0.02 |

|

B7000-E-T-P4S |

10 |

26 |

8 |

4.05 |

2 |

60000 |

95000 |

0.02 |

|

B7001-C-T-P4S |

12 |

28 |

8 |

4.75 |

2.6 |

60000 |

90000 |

0.02 |

|

B7001-E-T-P4S |

12 |

28 |

8 |

4.55 |

2.5 |

53000 |

85000 |

0.02 |

|

B7002-C-T-P4S |

15 |

32 |

9 |

6.2 |

3.4 |

53000 |

80000 |

0.03 |

|

B7002-E-T-P4S |

15 |

32 |

9 |

6 |

3.25 |

45000 |

70000 |

0.03 |

|

B7003-C-T-P4S |

17 |

35 |

10 |

8.65 |

4.9 |

45000 |

70000 |

0.04 |

|

B7003-E-T-P4S |

17 |

35 |

10 |

8.3 |

4.75 |

43000 |

63000 |

0.04 |

|

B7004-C-T-P4S |

20 |

42 |

12 |

10.4 |

6 |

38000 |

60000 |

0.07 |

|

B7004-E-T-P4S |

20 |

42 |

12 |

10 |

5.7 |

34000 |

53000 |

0.07 |

|

B7005-C-T-P4S |

25 |

47 |

12 |

14.6 |

9.15 |

34000 |

50000 |

0.08 |

|

B7005-E-T-P4S |

25 |

47 |

12 |

13.7 |

8.65 |

30000 |

45000 |

0.08 |

|

B7006-C-T-P4S |

30 |

55 |

13 |

15 |

10.2 |

28000 |

43000 |

0.11 |

|

B7006-E-T-P4S |

30 |

55 |

13 |

14.3 |

9.8 |

24000 |

38000 |

0.11 |

|

B7007-C-T-P4S |

35 |

62 |

14 |

19 |

13.7 |

24000 |

38000 |

0.15 |

|

B7007-E-T-P4S |

35 |

62 |

14 |

18.3 |

12.9 |

22000 |

34000 |

0.15 |

|

B7008-C-T-P4S |

40 |

68 |

15 |

20.4 |

16 |

22000 |

34000 |

0.19 |

|

B7008-E-T-P4S |

40 |

68 |

15 |

19.6 |

15 |

20000 |

30000 |

0.19 |

|

B7009-C-T-P4S |

45 |

75 |

16 |

27.5 |

21.2 |

19000 |

30000 |

0.23 |

|

B7009-E-T-P4S |

45 |

75 |

16 |

26.5 |

20 |

17000 |

26000 |

0.23 |

|

B7010-C-T-P4S |

50 |

80 |

16 |

28.5 |

22.8 |

18000 |

28000 |

0.25 |

|

B7010-E-T-P4S |

50 |

80 |

16 |

27 |

21.6 |

16000 |

24000 |

0.25 |

|

B7011-C-T-P4S |

55 |

90 |

18 |

38 |

31 |

16000 |

24000 |

0.37 |

|

B7011-E-T-P4S |

55 |

90 |

18 |

36 |

29 |

14000 |

22000 |

0.37 |

|

B7012-C-T-P4S |

60 |

95 |

18 |

39 |

33.5 |

15000 |

22000 |

0.4 |

|

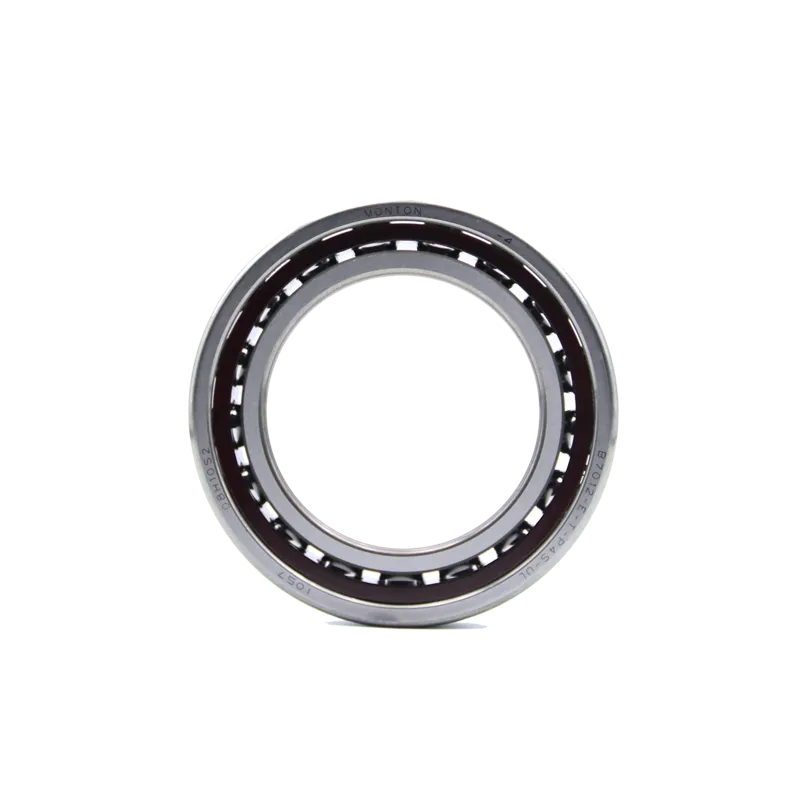

B7012-E-T-P4S |

60 |

95 |

18 |

36.5 |

31.5 |

13000 |

20000 |

0.4 |

|

B7013-C-T-P4S |

65 |

100 |

18 |

40 |

35.5 |

14000 |

22000 |

0.42 |

|

B7013-E-T-P4S |

65 |

100 |

18 |

38 |

33.5 |

13000 |

19000 |

0.42 |

|

B7014-C-T-P4S |

70 |

110 |

20 |

50 |

43 |

13000 |

20000 |

0.59 |

|

B7014-E-T-P4S |

70 |

110 |

20 |

46.5 |

41.5 |

11000 |

18000 |

0.59 |

|

B7015-C-T-P4S |

75 |

115 |

20 |

51 |

46.5 |

12000 |

19000 |

0.62 |

|

B7015-E-T-P4S |

75 |

115 |

20 |

48 |

44 |

11000 |

17000 |

0.62 |

|

B7016-C-T-P4S |

80 |

125 |

22 |

63 |

58.5 |

11000 |

17000 |

0.84 |

|

B7016-E-T-P4S |

80 |

125 |

22 |

60 |

55 |

10000 |

15000 |

0.84 |

|

B7017-C-T-P4S |

85 |

130 |

22 |

65.5 |

62 |

11000 |

16000 |

0.89 |

|

B7017-E-T-P4S |

85 |

130 |

22 |

62 |

58.5 |

9500 |

15000 |

0.89 |

|

B7018-C-T-P4S |

90 |

140 |

24 |

76.5 |

72 |

10000 |

15000 |

1.15 |

|

B7018-E-T-P4S |

90 |

140 |

24 |

72 |

68 |

9000 |

14000 |

1.15 |

|

B7019-C-T-P4S |

95 |

145 |

24 |

78 |

76.5 |

9500 |

15000 |

1.2 |

|

B7019-E-T-P4S |

95 |

145 |

24 |

75 |

72 |

8500 |

13000 |

1.2 |

|

B7020-C-T-P4S |

100 |

150 |

24 |

81.5 |

81.5 |

9000 |

14000 |

1.26 |

|

B7020-E-T-P4S |

100 |

150 |

24 |

76.5 |

76.5 |

8000 |

13000 |

1.26 |

|

B7021-C-T-P4S |

105 |

160 |

26 |

83 |

85 |

8500 |

13000 |

1.6 |

|

B7021-E-T-P4S |

105 |

160 |

26 |

78 |

81.5 |

7500 |

12000 |

1.6 |

|

B7022-C-T-P4S |

110 |

170 |

28 |

110 |

110 |

8000 |

12000 |

2 |

|

B7022-E-T-P4S |

110 |

170 |

28 |

104 |

104 |

7500 |

12000 |

2 |

|

B7024-C-T-P4S |

120 |

180 |

28 |

112 |

116 |

7500 |

12000 |

2.1 |

|

B7024-E-T-P4S |

120 |

180 |

28 |

106 |

110 |

6700 |

10000 |

2.1 |

|

B7026-C-T-P4S |

130 |

200 |

33 |

143 |

150 |

6700 |

10000 |

3.2 |

|

B7026-E-T-P4S |

130 |

200 |

33 |

137 |

143 |

6000 |

9500 |

3.2 |

|

B7028-C-T-P4S |

140 |

210 |

33 |

146 |

160 |

6300 |

10000 |

3.4 |

|

B7028-E-T-P4S |

140 |

210 |

33 |

140 |

150 |

5600 |

9000 |

3.4 |

|

B7030-C-T-P4S |

150 |

225 |

35 |

183 |

193 |

6000 |

9000 |

4.1 |

|

B7030-E-T-P4S |

150 |

225 |

35 |

173 |

186 |

5300 |

8000 |

4.1 |

|

B7032-C-T-P4S |

160 |

240 |

38 |

190 |

208 |

5600 |

8500 |

5.1 |

|

B7032-E-T-P4S |

160 |

240 |

38 |

176 |

196 |

5000 |

7500 |

5.1 |

|

B7034-C-T-P4S |

170 |

260 |

42 |

236 |

270 |

5300 |

8000 |

6.7 |

|

B7034-E-T-P4S |

170 |

260 |

42 |

224 |

255 |

4500 |

7000 |

6.7 |

|

B7036-C-T-P4S |

180 |

280 |

46 |

245 |

285 |

4800 |

7500 |

8.9 |

|

B7036-E-T-P4S |

180 |

280 |

46 |

232 |

275 |

4300 |

6700 |

8.9 |

|

B7038-C-T-P4S |

190 |

290 |

46 |

250 |

305 |

4500 |

7000 |

9.3 |

|

B7038-E-T-P4S |

190 |

290 |

46 |

236 |

290 |

4000 |

6300 |

9.3 |

|

B7040-C-T-P4S |

200 |

310 |

51 |

305 |

390 |

4300 |

6700 |

12 |

|

B7040-E-T-P4S |

200 |

310 |

51 |

290 |

365 |

3800 |

6000 |

12 |

|

B7044-C-T-P4S |

220 |

340 |

56 |

325 |

440 |

4000 |

6000 |

16 |

|

B7044-E-T-P4S |

220 |

340 |

56 |

310 |

415 |

3600 |

5300 |

16 |

|

B7048-C-T-P4S |

240 |

360 |

56 |

335 |

465 |

3600 |

5600 |

17 |

|

B7048-E-T-P4S |

240 |

360 |

56 |

315 |

440 |

3200 |

5000 |

17 |

MONTON B70XX light series is mainly suitable for applications with large space and not too heavy load. MONTON provide customer with different products and combinations according to working conditions. MONTON can provide customers with products of different precision levels of P5, P4, and P2. Our hybrid ceramic ball bearings use silicon nitride Si3N4 ceramic balls, which have higher stiffness, higher speed, low friction, low loss, longer bearing lubrication service life, higher precision, and reduce the outer ring rolling contact stress at high speed. Universal matching bearings with the same bearing inner diameter deviation and the same bearing outer diameter deviation, a single bearing can be installed in any bearing arrangement requirements.

MONTON's bearingdesigns :

1. Single installation U (universal) or assembled in group ad D (Double) T (Triple) Q (Quater), etc.

2. Universal bearings or universal bearing sets

3. Bearings using steel balls or hybrid ceramic ball bearings

4. Open type or bearings with seals on both sides

5. Bearings directly lubricated through the circumferential lubrication grooves and radial lubrication holes on the outer ring of the bearing

6. Preload is divided into three types: light L, medium M, and heavy H

Main applications include:

1. Machining center (horizontal or vertical)

2. High speed milling machine

3. Lathe

4. External cylindrical and surface grinders

5. Boring machine

6. Cutting Machine tools for cutting or polishing stone and glass

7. Semiconductor industry, etc., fault detection units on silicon wafers

8. Marine gyro stabilizers

9. Telescopes

10. Gas turbine engines

11. Racing/supercar wheels

12. Medical equipment

13. Electric spindles

14. Spindle for PCB drilling

15. Woodworking machine tools

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and application. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating excellent user experience and rich benefits for every user.

If you have any questions about products and services, please contact the company's service department directly.