Designation

Dimensions

Basic loading

Limiting Speed

Weight

Dynamic

Static

nG Greas

nG Oil

d

D

B

Cr

C0r

Grease

Oil

m

mm

mm

mm

kN

kN

min

min

kg

B71900-C-T-P4S

10

22

6

3

1.53

75000

120000

0.009

B71900-E-T-P4S

10

22

6

2.9

1.46

70000

110000

0.009

B71901-C-T-P4S

12

24

6

3.35

1.86

67000

100000

0.01

B71901-E-T-P4S

12

24

6

3.2

1.76

60000

95000

0.01

B71902-C-T-P4S

15

28

7

5

2.9

56000

85000

0.02

B71902-E-T-P4S

15

28

7

4.8

2.75

50000

75000

0.02

B71903-C-T-P4S

17

30

7

5.3

3.15

50000

80000

0.02

B71903-E-T-P4S

17

30

7

5

3

45000

70000

0.02

B71904-C-T-P4S

20

37

9

7.35

4.55

43000

63000

0.03

B71904-E-T-P4S

20

37

9

6.95

4.4

38000

60000

0.03

B71905-C-T-P4S

25

42

9

8.15

5.7

36000

56000

0.04

B71905-E-T-P4S

25

42

9

7.8

5.5

32000

50000

0.04

B71906-C-T-P4S

30

47

9

8.65

6.55

30000

48000

0.05

B71906-E-T-P4S

30

47

9

8.15

6.3

28000

43000

0.05

B71907-C-T-P4S

35

55

10

11.8

9.5

26000

40000

0.07

B71907-E-T-P4S

35

55

10

11

9

24000

36000

0.07

B71908-C-T-P4S

40

62

12

17.6

13.7

24000

36000

0.11

B71908-E-T-P4S

40

62

12

16.6

13.2

20000

32000

0.11

B71909-C-T-P4S

45

68

12

18.6

15.6

20000

32000

0.13

B71909-E-T-P4S

45

68

12

17.6

15

19000

28000

0.13

B71910-C-T-P4S

50

72

12

19

16.6

19000

30000

0.13

B71910-E-T-P4S

50

72

12

18

15.6

17000

26000

0.13

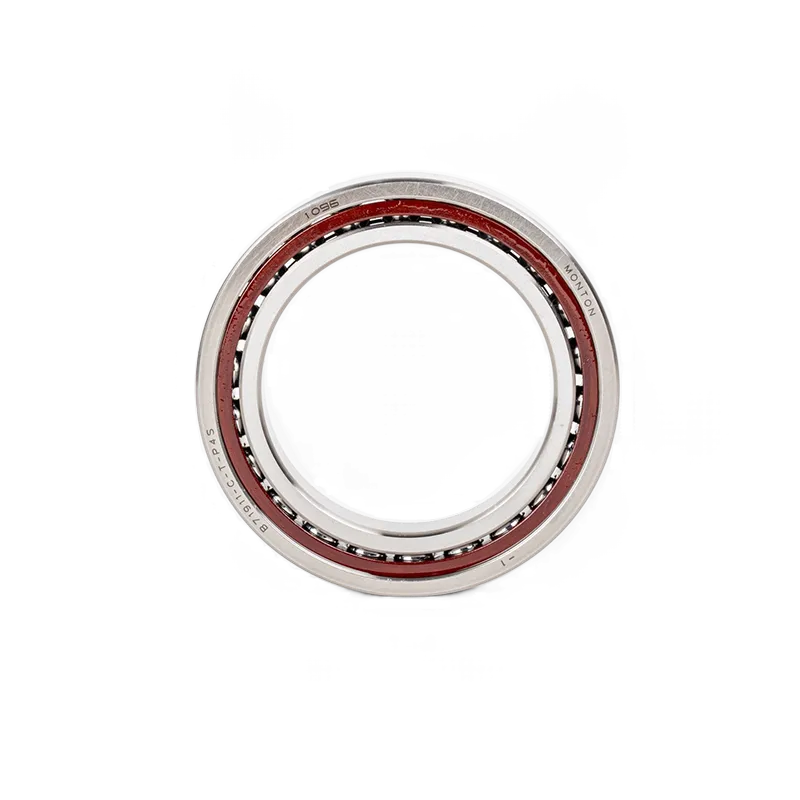

B71911-C-T-P4S

55

80

13

22.8

20.4

17000

26000

0.18

B71911-E-T-P4S

55

80

13

21.6

19.3

15000

24000

0.18

B71912-C-T-P4S

60

85

13

24

22.8

16000

24000

0.19

B71912-E-T-P4S

60

85

13

22.8

21.6

14000

22000

0.19

B71913-C-T-P4S

65

90

13

24.5

24

15000

22000

0.2

B71913-E-T-P4S

65

90

13

22.8

22.4

13000

20000

0.2

B71914-C-T-P4S

70

100

16

33.5

32.5

14000

20000

0.33

B71914-E-T-P4S

70

100

16

31.5

31

12000

19000

0.33

B71915-C-T-P4S

75

105

16

34

34.5

13000

20000

0.35

B71915-E-T-P4S

75

105

16

32

32.5

11000

18000

0.35

B71916-C-T-P4S

80

110

16

34.5

36

12000

19000

0.37

B71916-E-T-P4S

80

110

16

32.5

34

11000

17000

0.37

B71917-C-T-P4S

85

120

18

45

46.5

11000

17000

0.53

B71917-E-T-P4S

85

120

18

42.5

44

10000

15000

0.53

B71918-C-T-P4S

90

125

18

45.5

49

11000

16000

0.55

B71918-E-T-P4S

90

125

18

43

46.5

9500

15000

0.55

B71919-C-T-P4S

95

130

18

46.5

51

10000

16000

0.58

B71919-E-T-P4S

95

130

18

44

48

9000

14000

0.58

B71920-C-T-P4S

100

140

20

58.5

64

9500

14000

0.79

B71920-E-T-P4S

100

140

20

55

60

8500

13000

0.79

B71921-C-T-P4S

105

145

20

58.5

64

9000

14000

0.8

B71921-E-T-P4S

105

145

20

55

60

8000

13000

0.8

B71922-C-T-P4S

110

150

20

58.5

67

8500

13000

0.8

B71922-E-T-P4S

110

150

20

56

63

8000

12000

0.8

B71924-C-T-P4S

120

165

22

73.5

85

8000

12000

1.2

B71924-E-T-P4S

120

165

22

69.5

80

7000

11000

1.2

B71926-C-T-P4S

130

180

24

86.5

100

7000

11000

1.5

B71926-E-T-P4S

130

180

24

81.5

95

6700

10000

1.5

B71928-C-T-P4S

140

190

24

90

108

6700

10000

1.6

B71928-E-T-P4S

140

190

24

85

102

6000

9500

1.6

B71930-C-T-P4S

150

210

28

122

143

6300

9500

2.5

B71930-E-T-P4S

150

210

28

114

134

5600

8500

2.5

B71932-C-T-P4S

160

220

28

125

150

6000

9000

2.7

B71932-E-T-P4S

160

220

28

116

140

5300

8000

2.7

B71934-C-T-P4S

170

230

28

129

163

5600

8500

2.8

B71934-E-T-P4S

170

230

28

122

150

5000

7500

2.8

B71936-C-T-P4S

180

250

33

163

204

5300

8000

4.2

B71936-E-T-P4S

180

250

33

156

193

4500

7000

4.2

B71938-C-T-P4S

190

260

33

166

212

5000

7500

4.4

B71938-E-T-P4S

190

260

33

156

200

4500

6700

4.4

B71940-C-T-P4S

200

280

38

204

255

4500

7000

6.1

B71940-E-T-P4S

200

280

38

193

240

4000

6300

6.1

B71944-C-T-P4S

220

300

38

216

285

4300

6700

6.7

B71944-E-T-P4S

220

300

38

204

270

3800

6000

6.7

B71948-C-T-P4S

240

320

38

224

310

4000

6000

7.2

B71948-E-T-P4S

240

320

38

212

285

3600

5300

7.2

B71952-C-T-P4S

260

360

46

285

415

3600

5300

12.1

B71952-E-T-P4S

260

360

46

270

390

3200

4800

12.1

B71956-C-T-P4S

280

380

46

300

450

3200

5000

12.9

B71956-E-T-P4S

280

380

46

280

425

3000

4500

12.9

B71960-C-T-P4S

300

420

56

360

570

3000

4500

20.4

B71960-E-T-P4S

300

420

56

340

540

2800

4300

20.4

B71964-C-T-P4S

320

440

56

375

620

2800

4300

21.6

B71964-E-T-P4S

320

440

56

355

585

2600

4000

21.6

B71968-C-T-P4S

340

460

56

380

640

2800

4300

22.7

B71968-E-T-P4S

340

460

56

360

610

2400

3800

22.7

B71972-C-T-P4S

360

480

56

390

695

2600

4000

23.9

B71972-E-T-P4S

360

480

56

375

640

2400

3600

23.9

B71976-C-T-P4S

380

520

65

490

900

2400

3600

35.1

B71976-E-T-P4S

380

520

65

465

850

2200

3400

35.1

B71980-C-T-P4S

400

540

65

500

950

2200

3600

35.9

B71980-E-T-P4S

400

540

65

475

880

2000

3200

35.9

B71984-C-T-P4S

420

560

65

510

980

2200

3400

37.6

B71984-E-T-P4S

420

560

65

475

915

2000

3000

37.6

B71988-C-T-P4S

440

600

74

520

1040

2000

3200

46.5

B71988-E-T-P4S

440

600

74

490

956

1900

2800

46.5

B71992-C-T-P4S

460

620

74

530

1080

2000

3000

55.4

B71992-E-T-P4S

460

620

74

500

1000

1800

2800

55.4

B71996-C-T-P4S

480

650

78

530

1100

1900

3000

61.8

B71996-E-T-P4S

480

650

78

500

1020

1700

2600

61.8

B719/500-C-T-P4S

500

670

78

550

1160

1800

2800

68.2

B719/500-C-T-P4S

500

670

78

520

1080

1600

2600

68.2

Smaller and lighter balls reduce the centrifugal load acting on the outer ring raceway, thereby reducing the rolling contact surface stress. Since smaller balls require less space, the bearing rings have a larger cross-sectional height, making them insensitive to deformation caused by irregularities in the bearing mounting surface, bearing seat or shaft. The outer ring of the direct-lubricated bearing has an annular groove with two lubrication holes and two annular grooves equipped with O-rings for direct oil lubrication. In applications where high speeds are required, bearings equipped with ceramic balls and capable of direct oil lubrication can exert their performance.

MONTON's different bearing variant designs include:

1. Single installation U (universal) or assembled in group ad D (Double) T (Triple) Q (Quater), etc.

2. Universal bearings or universal bearing sets

3. Bearings using steel balls or hybrid ceramic ball bearings

4. Open bearings or bearings with seals on both sides

5. Bearings directly lubricated through the circumferential lubrication grooves and radial lubrication holes on the outer ring of the bearing

6. Preload is divided into three types: light L, medium M, and heavy H

Main applications include:

1. Machining center

2. Milling machine/lathe/boring machine

3. External cylindrical and surface grinders

4. Cutting or polishing stone and glass Machine tools

5. Semiconductor industry, etc., fault detection unit on silicon wafers

6. Marine gyro stabilizers

7. Telescopes

8. Gas turbine engines

9. Racing/supercar wheels

10. Medical equipment

11. Spindle for PCB drilling

12. Woodworking machine tools

13. Turbomolecular pumps

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and application. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating excellent user experience and rich benefits for every user.

If you have any questions about products and services, please contact the company's service department directly.