Designation

Dimension

Basic Load

Limited speed

Weight

d

D

B

Cr

C0r

Greas

Mass

mm

mm

mm

KN

KN

r/min

kg

H7000C-2RZHQ1/P4

10

26

8

2.2

1.2

90000

0.02

H7000AC-2RZHQ1/P4

10

26

8

2.1

1.2

75000

0.02

H7001C-2RZHQ1/P4

12

28

8

2.2

1.3

80000

0.02

H7001AC-2RZHQ1/P4

12

28

8

2.0

1.2

70000

0.02

H7002C-2RZHQ1/P4

15

32

9

3.6

2.3

70000

0.03

H7002AC-2RZHQ1/P4

15

32

9

3.5

2.2

60000

0.03

H7003C-2RZHQ1/P4

17

35

10

3.8

2.5

63000

0.01

H7003AC-2RZHQ1/P4

17

35

10

3.6

2.3

53000

0.04

H7004C-2RZHQ1/P4

20

42

12

6.1

4.3

53000

0.08

H7004AC-2RZHQ1/P4

20

45

12

5.8

4.1

45000

0.08

H7005C-2RZHQ1/P4

25

47

12

6.2

4.6

45000

0.09

H7005AC-2RZHQ1/P4

25

47

12

5.8

4.4

38000

0.09

H7006C-2RZHQ1/P4

30

55

13

8.6

6.6

38000

0.13

H7006AC-2RZHQ1/P4

30

55

13

8.1

6.3

32000

0.13

H7007C-2RZHQ1/P4

35

62

14

9.2

7.8

34000

0.18

H7007AC-2RZHQ1/P4

35

62

14

8.7

7.4

28000

0.18

H7008C-2RZHQ1/P4

40

68

15

9.8

8.9

30000

0.2

H7008AC-2RZHQ1/P4

40

68

15

9.3

8.4

26000

0.2

H7009C-2RZHQ1/P4

45

78

16

12.5

11.4

26000

0.26

H7009AC-2RZHQ1/P4

45

75

16

11.8

10.7

24000

0.26

H7010C-2RZHQ1/P4

50

80

16

12.9

12.4

24000

0.28

H7010AC-2RZHQ1/P4

50

80

16

12.2

11.7

22000

0.28

H7011C-2RZHQ1/P4

55

90

18

17.5

16.8

22000

0.41

H7011AC-2RZHQ1/P4

55

90

18

17.5

16.8

19000

0.41

H7012 C-2RZHQ1/P4

60

95

18

19.3

19.3

20000

0.43

H7012 AC-2RZHQ1/P4

60

95

18

18.2

18.2

18000

0.43

H7013 C-2RZHQ1/P4

65

100

18

19.9

20.8

20000

0.46

H7013 AC-2RZHQ1/P4

65

100

18

18.8

19.7

17000

0.46

H7014 C-2RZHQ1/P4

70

110

20

25.9

26.7

18000

0.64

H7014 AC-2RZHQ1/P4

70

110

20

24.4

25.2

15000

0.64

H7015 C-2RZHQ1/P4

75

115

20

26.2

27.8

17000

0.67

H7015 AC-2RZHQ1/P4

75

115

20

24.7

26.3

15000

0.67

H7016 C-2RZHQ1/P4

80

125

22

31.2

33.5

16000

0.9

H7016 AC-2RZHQ1/P4

80

125

22

29.5

31.7

13000

0.9

H7017C-2RZHQ1/P4

85

130

22

61.6

34.9

15000

0.94

H7017AC-2RZHQ1/P4

85

130

22

29.9

32.9

13000

0.94

H7018C-2RZHQ1/P4

90

140

24

37.1

41.4

14000

1.24

H7018AC-2RZHQ1/P4

90

140

24

35.1

39.1

12000

1.24

H7019C-2RZHQ1/P4

95

145

24

37.6

43.0

13000

1.26

H7019AC-2RZHQ1/P4

95

145

24

35.5

40.6

11000

1.26

H7020C-2RZHQ1/P4

100

150

24

38.1

44.6

12000

1.34

H7020AC-2RZHQ1/P4

100

150

24

36.0

42.1

11000

1.34

H7021 C-2RZHQ1/P4

105

160

26

49.1

56.3

12000

1.66

H7021 AC-2RZHQ1/P4

105

160

26

46.4

53.2

10000

1.66

H7022C-2RZHQ1/P4

110

170

28

49.7

58.5

11000

2.16

H7022AC-2RZHQ1/P4

110

170

28

46.9

55.3

9000

2.16

H7024 C-2RZHQ1/P4

120

180

28

51.0

62.8

10000

2.21

H7024 AC-2RZHQ1/P4

120

180

28

48.2

58.5

8500

2.21

H7026 C-2RZHQ1/P4

130

200

33

65.4

81.5

9000

3.52

H7026 AC-2RZHQ1/P4

130

200

33

61.0

77.0

7500

3.52

H7028 C-2RZHQ1/P4

140

210

33

67.1

87.0

7500

3.73

H7028 AC-2RZHQ1/P4

140

210

33

63.4

82.2

7000

3.73

H7030 C-2RZHQ1/P4

150

225

35

82.4

106.5

6700

4.46

H7030 AC-2RZHQ1/P4

150

225

35

77.8

100.6

6300

4.46

H7032 C-2RZHQ1/P4

160

240

38

84.3

113.4

6300

5.64

H7032 AC-2RZHQ1/P4

160

240

38

79.6

107.2

5600

5.64

H7034 C-2RZHQ1/P4

170

260

42

102.7

139.6

6000

7.95

H7034 AC-2RZHQ1/P4

170

260

42

97.0

131.9

5300

7.95

H7036 C-2RZHQ1/P4

180

280

46

104.8

148.3

5300

10.2

H7036 AC-2RZHQ1/P4

180

280

46

99.0

140.1

4800

10.2

H7038 C-2RZHQ1/P4

190

290

45

116.9

164.3

4500

10.36

H7038 AC-2RZHQ1/P4

190

290

45

126.4

184.4

4500

13.81

H7040 C-2RZHQ1/P4

200

310

51

126.4

184.4

4500

13.81

H7040 AC-2RZHQ1/P4

200

310

51

119.4

174.2

4300

13.81

H7044 C-2RZHQ1/P4

220

340

56

147.7

219.5

4300

18.16

H7044AC-2RZHQ1/P4

220

340

56

139.5

207.4

4000

18.16

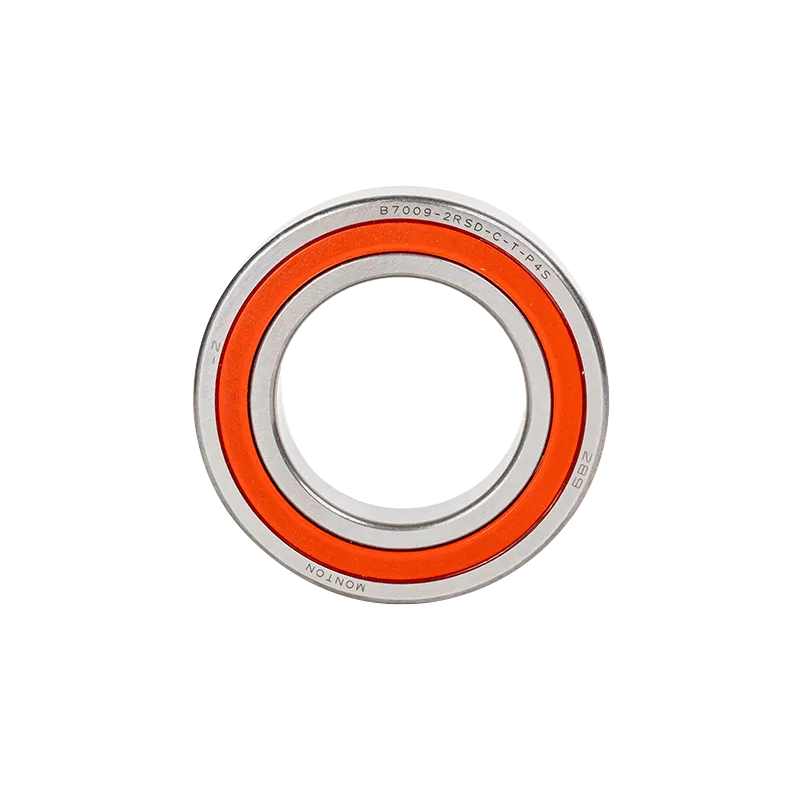

Engraving machine spindle bearing mainly use high quality bearing steel (GCr15), imported ceramic balls, and filling with Kluber grease. The bearing accuracy can reach P4 and P2 .

When choosing the spindle bearing , we should be pay attention to the following:

1. Bearing load capacity. Select the bearing that can meets the requirements according to the actual working static load and dynamic load of the engraving machine.

2. Working speed. Select the bearing according to the maximum spindle speed to ensure that the bearing can run stably at high speed.

3. The accuracy level should be selected well. Different engraving machines have different requirements for bearing accuracy. High-precision bearings have good stability during processing and can effectively reduce workpiece errors.

4. Durability of bearings. Try to choose wear-resistant and fatigue-resistant bearings so that the engraving machine is not easily damaged when working for a long time, reducing the company's maintenance costs.

5. Lubrication method. Choose the appropriate lubrication method according to the working environment, such as oil lubrication or grease lubrication, which should match the working conditions of the bearing.

6. When the engraving machine is running in a working environment with a lot of dust or water vapor, it is recommended to choose bearings with seals or protective devices.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.