Designation

Dimensions

Basic Loading

Limiting Speed

Weight

d

D

B

Dynamic C

Static C0

Greas

Oil

mm

kN

r/min

kg

H71902C

15

28

7

3.19

1.4

75000

115000

0.015

H71902C/HC

15

28

7

3.19

1.4

90000

140000

0.013

H71902AC

15

28

7

3.02

1.34

68000

106000

0.015

H71902AC/HC

15

28

7

3.02

1.34

83000

127000

0.013

H7002C

15

32

9

4.42

1.93

68000

106000

0.028

H7002C/HC

15

32

9

4.42

1.93

83000

127000

0.025

H7002AC

15

32

9

4.23

1.83

63000

95000

0.028

H7002AC/HC

15

32

9

4.23

1.83

75000

115000

0.025

H71903C

17

30

7

3.32

1.56

70000

106000

0.016

H71903C/HC

17

30

7

3.32

1.56

83000

127000

0.014

H71903AC

17

30

7

3.19

1.46

63000

95000

0.016

H71903AC/HC

17

30

7

3.19

1.46

75000

115000

0.014

H7003C

17

35

10

5.85

2.55

63000

95000

0.035

H7003C/HC

17

35

10

5.85

2.55

75000

115000

0.03

H7003AC

17

35

10

5.59

2.45

56000

88000

0.035

H7003AC/HC

17

35

10

5.59

2.45

68000

103000

0.03

H71904C

20

37

9

4.88

2.4

56000

88000

0.036

H71904C/HC

20

37

9

4.88

2.4

68000

106000

0.032

H71904AC

20

37

9

4.68

2.28

52000

78000

0.036

H71904AC/HC

20

37

9

4.68

2.28

60000

95000

0.032

H7004C

20

42

12

7.41

3.35

54000

83000

0.064

H7004C/HC

20

42

12

7.41

3.35

65000

100000

0.056

H7004AC

20

42

12

7.15

3.25

48000

75000

0.064

H7004AC/HC

20

42

12

7.15

3.25

58000

88000

0.056

H71905C

25

42

9

5.27

2.85

49000

75000

0.04

H71905C/HC

25

42

9

5.27

2.85

58000

90000

0.036

H71905AC

25

42

9

4.94

2.7

44000

68000

0.04

H71905AC/HC

25

42

9

4.94

2.7

52000

83000

0.036

H7005C

25

47

12

8.32

4.15

46000

70000

0.074

H7005C/HC

25

47

12

8.32

4.15

56000

85000

0.065

H7005AC

25

47

12

7.93

3.9

42000

63000

0.074

H7005AC/HC

25

47

12

7.93

3.9

50000

75000

0.065

H71906C

30

47

9

5.59

3.25

41000

63000

0.05

H71906C/HC

30

47

9

5.59

3.25

49000

75000

0.045

H71906AC

30

47

9

5.27

3.1

37000

58000

0.05

H71906AC/HC

30

47

9

5.27

3.1

44000

70000

0.045

H7006C

30

55

13

9.36

5.2

39000

60000

0.11

H7006C/HC

30

55

13

9.36

5.2

47000

73000

0.1

H7006AC

30

55

13

8.84

5

35000

54000

0.11

H7006AC/HC

30

55

13

8.84

5

42000

65000

0.1

H71907C

35

55

10

7.61

4.75

36000

54000

0.075

H71907C/HC

35

55

10

7.61

4.75

43000

65000

0.067

H71907AC

35

55

10

7.28

4.5

32000

50000

0.075

H71907AC/HC

35

55

10

7.28

4.5

38000

60000

0.067

H7007C

35

62

14

11.4

6.55

34000

50000

0.15

H7007C/HC

35

62

14

11.4

6.55

40000

63000

0.13

H7007AC

35

62

14

11.1

6.3

31000

46000

0.15

H7007AC/HC

35

62

14

11.1

6.3

36000

56000

0.13

H71908C

40

62

12

9.75

6.1

32000

49000

0.1

H71908C/HC

40

62

12

9.75

6.1

38000

58000

0.088

H71908AC

40

62

12

9.23

5.85

28000

44000

0.1

H71908AC/HC

40

62

12

9.23

5.85

34000

52000

0.088

H7008C

40

68

15

12.4

7.65

30000

45000

0.19

H7008C/HC

40

68

15

12.4

7.65

36000

56000

0.17

H7008AC

40

68

15

11.7

7.2

27000

41000

0.19

H7008AC/HC

40

68

15

11.7

7.2

32000

50000

0.17

H71909C

45

68

12

10.1

6.95

29000

44000

0.13

H71909C/HC

45

68

12

10.1

6.95

34000

52000

0.12

H71909AC

45

68

12

9.75

6.55

25000

39000

0.13

H71909AC/HC

45

68

12

9.75

6.55

30000

47000

0.12

H7009C

45

75

16

13

8.5

27000

41000

0.24

H7009C/HC

45

75

16

13

8.5

32000

50000

0.22

H7009AC

45

75

16

12.1

8.15

24000

37000

0.24

H7009AC/HC

45

75

16

12.1

8.15

29000

45000

0.22

H71910C

50

72

12

12.7

8.65

26000

40000

0.13

H71910C/HC

50

72

12

12.7

8.65

32000

48000

0.11

H71910AC

50

72

12

12.1

8.15

23000

36000

0.13

H71910AC/HC

50

72

12

12.1

8.15

28000

43000

0.11

H7010C

50

80

16

15.6

10.6

25000

38000

0.25

H7010C/HC

50

80

16

15.6

10.6

30000

46000

0.23

H7010AC

50

80

16

14.8

10

23000

34000

0.25

H7010AC/HC

50

80

16

14.8

10

27000

41000

0.23

H71911C

55

80

13

15.3

10.6

24000

36000

0.17

H71911C/HC

55

80

13

15.3

10.6

28000

43000

0.14

H71911AC

55

80

13

14.6

10.2

21000

32000

0.17

H71911AC/HC

55

80

13

14.6

10.2

25000

39000

0.14

H7011C

55

90

18

16.8

12.2

22000

34000

0.39

H7011C/HC

55

90

18

16.8

12.2

25000

39000

0.36

H7011AC

55

90

18

15.9

11.6

19000

30000

0.39

H7011AC/HC

55

90

18

15.9

11.6

23000

35000

0.36

H71912 C

60

85

13

16.3

11.8

22000

34 000

0.19

H71912 C/HC

60

85

13

16.3

11.8

26000

40 000

0.16

H71912 AC

60

85

13

15.3

11.2

19500

30 000

0.19

H71912 AC/HC

60

85

13

15.3

11.2

23000

36 000

0.16

H7012 C

60

95

18

17.2

12.9

20000

31 000

0.42

H7012 C/HC

60

95

18

17.2

12.9

24000

37 000

0.39

H7012 AC

60

95

18

16.3

12.2

18000

28 000

0.42

H7012 AC/HC

60

95

18

16.3

12.2

22000

33 000

0.39

H71913 C

65

90

13

16.5

12.5

20000

31 000

0.2

H71913 C/HC

65

90

13

16.5

12.5

24000

38 000

0.17

H71913 AC

65

90

13

15.6

11.8

18000

28 000

0.2

H71913 AC/HC

65

90

13

15.6

11.8

22000

34 000

0.17

H7013 C

65

100

18

20.3

15.6

19000

30 000

0.43

H7013 C/HC

65

100

18

20.3

15.6

22000

34 000

0.39

H7013 AC

65

100

18

19.5

14.6

17000

26 000

0.43

H7013 AC/HC

65

100

18

19.5

14.6

20000

31 000

0.39

H71914 C

70

100

16

22.1

16.3

18500

28 000

0.32

H71914 C/HC

70

100

16

22.1

16.3

22000

34 000

0.27

H71914 AC

70

100

16

20.8

15.3

16500

26 000

0.32

H71914 AC/HC

70

100

16

20.8

15.3

20000

31 000

0.27

H7014 C

70

110

20

23.8

18.3

17000

27 000

0.61

H7014 C/HC

70

110

20

23.8

18.3

20500

32 000

0.56

H7014 AC

70

110

20

22.5

17.3

15500

24 000

0.61

H7014 AC/HC

70

110

20

22.5

17.3

18500

29 000

0.56

H71915 C

75

105

16

22.5

17

17500

27 000

0.34

H71915 C/HC

75

105

16

22.5

17

20500

32 000

0.29

H71915 AC

75

105

16

21.2

16.3

15500

24 000

0.34

H71915 AC/HC

75

105

16

21.2

16.3

18500

29 000

0.29

H7015 C

75

115

20

26

21.6

16000

26 000

0.65

H7015 C/HC

75

115

20

26

21.6

19000

29 000

0.59

H7015 AC

75

115

20

24.7

20.4

14500

23 000

0.65

H7015 AC/HC

75

115

20

24.7

20.4

17000

27 000

0.59

H71916 C

80

110

16

22.5

18

16500

25 000

0.36

H71916 C/HC

80

110

16

22.5

18

19000

30 000

0.31

H71916 AC

80

110

16

21.2

17

14500

22 000

0.36

H71916 AC/HC

80

110

16

21.2

17

17500

27 000

0.31

H7016 C

80

125

22

33.8

28

15000

24 000

0.86

H7016 C/HC

80

125

22

33.8

28

17500

27 000

0.77

H7016 AC

80

125

22

32.5

26.5

13700

21 000

0.86

H7016 AC/HC

80

125

22

32.5

26.5

15500

24 000

0.77

H71917C

85

120

18

29.6

23.2

15 500

24000

0.5

H71917C/HC

85

120

18

29.6

23.2

18 000

28000

0.42

H71917AC

85

120

18

28.1

22

13 700

21000

0.5

H71917AC/HC

85

120

18

28.1

22

16 500

25000

0.42

H7017C

85

130

22

34.5

29

14 000

22000

0.9

H7017C/HC

85

130

22

34.5

29

16 500

26000

0.81

H7017AC

85

130

22

32.5

28

13 000

20000

0.9

H7017AC/HC

85

130

22

32.5

28

15 000

23000

0.81

H71918C

90

125

18

30.2

24.5

14 500

22000

0.54

H71918C/HC

90

125

18

30.2

24.5

17 000

27000

0.46

H71918AC

90

125

18

28.6

23.2

13 000

20000

0.54

H71918AC/HC

90

125

18

28.6

23.2

15 500

24000

0.46

H7018C

90

140

24

35.8

32

13 300

21000

1.2

H7018C/HC

90

140

24

35.8

32

15 500

24000

1.1

H7018AC

90

140

24

33.8

30

12 000

19000

1.2

H7018AC/HC

90

140

24

33.8

30

14 000

22000

1.1

H71919C

95

130

18

30.7

25.5

14 000

21000

0.56

H71919C/HC

95

130

18

30.7

25.5

16 000

25000

0.48

H71919AC

95

130

18

29.1

24

12 300

19000

0.56

H71919AC/HC

95

130

18

29.1

24

15 000

23000

0.48

H7019C

95

145

24

44.2

38

12 700

20000

1.2

H7019C/HC

95

145

24

44.2

38

15 000

23000

1.1

H7019AC

95

145

24

41.6

36

11 500

18000

1.2

H7019AC/HC

95

145

24

41.6

36

13 300

20500

1.1

H71920C

100

140

20

39

31.5

13 300

20500

0.77

H71920C/HC

100

140

20

39

31.5

15 500

24000

0.65

H71920AC

100

140

20

36.4

30

11 500

18000

0.77

H71920AC/HC

100

140

20

36.4

30

13 700

22000

0.65

H7020C

100

150

24

44.9

40

12 300

19000

1.35

H7020C/HC

100

150

24

44.9

40

14 500

22000

1.1

H7020AC

100

150

24

42.3

38

11 200

17500

1.25

H7020AC/HC

100

150

24

42.3

38

12 700

20000

1.1

H71922C

110

150

20

39.7

34.5

12 000

18000

0.83

H71922C/HC

110

150

20

39.7

34.5

14 000

22000

0.7

H71922AC

110

150

20

37.7

32.5

10 300

16000

0.83

H71922AC/HC

110

150

20

37.7

32.5

12 300

19000

0.7

H7022C

110

170

28

47.5

45

10 900

17000

2.1

H7022C/HC

110

170

28

47.5

45

12 700

20000

1.95

H7022AC

110

170

28

44.9

42.5

10 000

15500

2.1

H7022AC/HC

110

170

28

44.9

42.5

11 500

17500

1.95

H71924 C

120

165

22

47.5

40.5

11200

16000

1.1

H71924 C/HC

120

165

22

47.5

40.5

12700

19000

0.93

H71924 AC

120

165

22

44.9

38

9500

15000

1.1

H71924 AC/HC

120

165

22

44.9

38

11500

17500

0.93

H7024 C

120

180

28

57.2

55

9300

14500

2.2

H7024 C/HC

120

180

28

57.2

55

11200

17500

1.95

H7024 AC

120

180

28

54

52

8300

13000

2.2

H7024 AC/HC

120

180

28

54

52

10000

15500

1.95

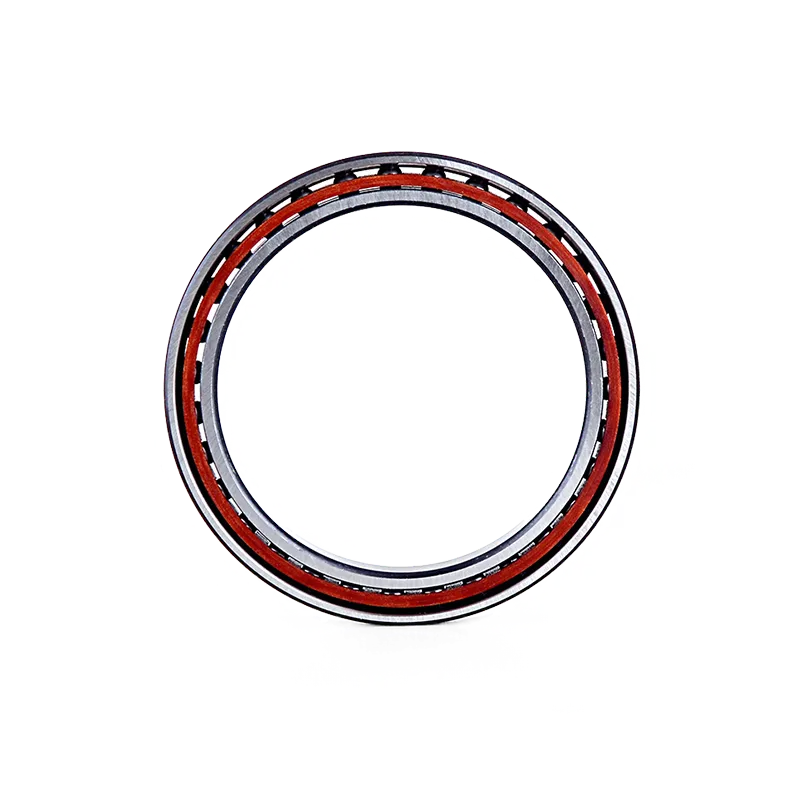

H7XXX series ultra-high speed angular contact ball bearings can meet the high speed performance of bearings, enhance running accuracy, improve system stiffness, reduce heat generation, reduce noise and vibration, which are the challenges faced by the bearing industry. In applications such as high-speed machining centers, milling machines, internal grinders and woodworking machines, they have high reliability and excellent operating results. Bearings with high-speed design are conducive to bearing radial loads and axial loads in one direction. The larger number of spherical rolling elements in the bearings is also conducive to bearing heavier loads.

The cage guided by the outer ring of the bearing is made of fiber-reinforced phenolic resin, which is to better provide lubrication for the contact area of the spherical rolling element raceway. The optimized guiding clearance between the cage and the outer ring significantly improves the performance under high-speed operation. The chamfer shape at the inner and outer rings has been optimized to improve the installation accuracy, depending on the bearing series and size. This not only simplifies the installation process, but also reduces the risk of damage to related components. The open fit of the H7XXX series ultra-high speed angular contact ball bearings gives the bearings high speed performance.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing materials and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products and creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.