Designation

Dimensions(mm)

Basic loading (kN)

Limiting Speed (min)

Weight

d

D

B

Dynamic

Stastic

HCS71900-C-T-P4S

10

22

6

1,360

760

100,000

0.01

HCS71900-E-T-P4S

10

22

6

1,290

720

85,000

0.009

HCS7000-C-T-P4S

10

26

8

1,900

1,100

90,000

0.02

HCS7000-E-T-P4S

10

26

8

1,800

1,050

75,000

0.02

HCS71901-C-T-P4S

12

24

6

1,410

840

90,000

0.01

HCS71901-E-T-P4S

12

24

6

1,330

800

75,000

0.010

HCS7001-C-T-P4S

12

28

8

1,870

1,130

80,000

0.02

HCS7001-E-T-P4S

12

28

8

1,770

1,070

70,000

0.02

HCS71902-C-T-P4S

15

28

7

1,940

1230

75,000

0.02

HCS71902-E-T-P4S

15

28

7

1,830

1170

63,000

0.015

HCS7002-C-T-P4S

15

32

9

2,600

1,700

70,000

0.03

HCS7002-E-T-P4S

15

32

9

2,450

1,610

60,000

0.03

HCS71903-C-T-P4S

17

30

7

1,990

1330

70,000

0.02

HCS71903-E-T-P4S

17

30

7

1,880

1260

60,000

0.017

HCS7003-C-T-P4S

17

35

10

2,650

1,840

63,000

0.04

HCS7003-E-T-P4S

17

35

10

2,500

1,740

53,000

0.04

HCS71904-C-T-P4S

20

37

9

2,700

1980

56,000

0.04

HCS71904-E-T-P4S

20

37

9

2,550

1870

48,000

0.041

HCS7004-C-T-P4S

20

42

12

4,300

3,200

53,000

0.07

HCS7004-E-T-P4S

20

42

12

4,100

3,000

45,000

0.07

HCS71905-C-T-P4S

25

42

9

2,900

2360

48,000

0.05

HCS71905-E-T-P4S

25

42

9

2,750

2200

40,000

0.047

HCS7005-C-T-P4S

25

47

12

4,350

3,450

45,000

0.09

HCS7005-E-T-P4S

25

47

12

4,100

3,250

38,000

0.09

HCS71906-C-T-P4S

30

47

9

4,400

3650

43,000

0.05

HCS71906-E-T-P4S

30

47

9

4,150

3450

36,000

0.047

HCS7006-C-T-P4S

30

55

13

6,000

4,950

38,000

0.12

HCS7006-E-T-P4S

30

55

13

5,700

4,700

32,000

0.12

HCS71907-C-T-P4S

35

55

10

4,800

4350

36,000

0.08

HCS71907-E-T-P4S

35

55

10

4,500

4050

30,000

0.076

HCS7007-C-T-P4S

35

62

14

6,500

5,800

34,000

0.17

HCS7007-E-T-P4S

35

62

14

6,100

5,400

28,000

0.17

HCS71908-C-T-P4S

40

62

12

5,000

4800

32,000

0.12

HCS71908-E-T-P4S

40

62

12

4,750

4500

28,000

0.122

HCS7008-C-T-P4S

40

68

15

6,800

6,500

30,000

0.21

HCS7008-E-T-P4S

40

68

15

6,400

6,100

26,000

0.21

HCS71909-C-T-P4S

45

68

12

6,900

6700

28,000

0.14

HCS71909-E-T-P4S

45

68

12

6,500

6300

24,000

0.135

HCS7009-C-T-P4S

45

75

16

8,900

8,600

26,000

0.25

HCS7009-E-T-P4S

45

75

16

8,400

8,000

24,000

0.25

HCS71910-C-T-P4S

50

72

12

7,100

7200

26,000

0.14

HCS71910-E-T-P4S

50

72

12

6,700

6700

22,000

0.136

HCS7010-C-T-P4S

50

80

16

9,200

9,200

24,000

0.27

HCS7010-E-T-P4S

50

80

16

8,700

8,600

22,000

0.27

HCS71911-C-T-P4S

55

80

13

9,300

9500

24,000

0.17

HCS71911-E-T-P4S

55

80

13

8,800

8800

20,000

0.170

HCS7011-C-T-P4S

55

90

18

13,000

13,200

22,000

0.35

HCS7011-E-T-P4S

55

90

18

12,200

12,300

19,000

0.35

HCS71912-C-T-P4S

60

85

13

9,600

10100

22,000

0.19

HCS71912-E-T-P4S

60

85

13

9,000

9400

19,000

0.190

HCS7012-C-T-P4S

60

95

18

13,400

14,000

20,000

0.39

HCS7012-E-T-P4S

60

95

18

12,600

13,100

18,000

0.39

HCS71913-C-T-P4S

65

90

13

9,900

10700

20,000

0.19

HCS71913-E-T-P4S

65

90

13

9,300

10000

18,000

0.194

HCS7013-C-T-P4S

65

100

18

13,800

15,000

20,000

0.40

HCS7013-E-T-P4S

65

100

18

13,000

14,000

17,000

0.40

HCS71914-C-T-P4S

70

100

16

12,700

14000

19,000

0.32

HCS71914-E-T-P4S

70

100

16

11,900

13100

16,000

0.321

HCS7014-C-T-P4S

70

110

20

18,000

19,500

18,000

0.61

HCS7014-E-T-P4S

70

110

20

17,000

18,200

15,000

0.61

HCS71915-C-T-P4S

75

105

16

13,000

14800

18,000

0.35

HCS71915-E-T-P4S

75

105

16

12,200

13800

15,000

0.346

HCS7015-C-T-P4S

75

115

20

18,200

20,100

17,000

0.65

HCS7015-E-T-P4S

75

115

20

17,200

18,700

15,000

0.64

HCS71916-C-T-P4S

80

110

16

14,500

16800

17,000

0.32

HCS71916-E-T-P4S

80

110

16

13,700

15600

15,000

0.317

HCS7016-C-T-P4S

80

125

22

21,700

24,300

16,000

0.87

HCS7016-E-T-P4S

80

125

22

20,500

22,700

13,000

0.87

HCS71917-C-T-P4S

85

120

18

15,100

18100

16,000

0.51

HCS71917-E-T-P4S

85

120

18

14,200

16900

13,000

0.511

HCS7017-C-T-P4S

85

130

22

22,000

25,000

15,000

0.92

HCS7017-E-T-P4S

85

130

22

20,700

23,400

13,000

0.92

HCS71918-C-T-P4S

90

125

18

16,400

19800

15,000

0.59

HCS71918-E-T-P4S

90

125

18

15,500

18500

13,000

0.587

HCS7018-C-T-P4S

90

140

24

26,000

30,000

14,000

1.19

HCS7018-E-T-P4S

90

140

24

24,300

28,000

12,000

1.18

HCS71919-C-T-P4S

95

130

18

16,800

20800

14,000

0.62

HCS71919-E-T-P4S

95

130

18

15,800

19400

12,000

0.614

HCS7019-C-T-P4S

95

145

24

26,000

31,000

13,000

1.24

HCS7019-E-T-P4S

95

145

24

24,600

28,500

11,000

1.24

HCS71920-C-T-P4S

100

140

20

20,200

25000

13,000

0.82

HCS71920-E-T-P4S

100

140

20

19,000

23400

11,000

0.816

HCS7020-C-T-P4S

100

150

24

26,500

31,500

12,000

1.29

HCS7020-E-T-P4S

100

150

24

24,900

29,500

11,000

1.29

HCS71921-C-T-P4S

105

145

20

20,700

26500

12,000

0.85

HCS71921-E-T-P4S

105

145

20

19,500

24600

11,000

0.850

HCS7021-C-T-P4S

105

160

26

34,000

40,500

12,000

1.59

HCS7021-E-T-P4S

105

160

26

32,000

38,000

10,000

1.59

HCS71922-C-T-P4S

110

150

20

24,100

30500

12,000

0.86

HCS71922-E-T-P4S

110

150

20

22,600

28500

10,000

0.858

HCS7022-C-T-P4S

110

170

28

34,500

42,000

11,000

2.05

HCS7022-E-T-P4S

110

170

28

32,500

39,000

9,000

2.05

HCS71924-C-T-P4S

120

165

22

25,000

33500

11,000

1.22

HCS71924-E-T-P4S

120

165

22

23,700

31000

9,000

1.220

HCS7024-C-T-P4S

120

180

28

35,500

44,500

10,000

2.20

HCS7024-E-T-P4S

120

180

28

33,000

41,500

8,500

2.20

HCS71926-C-T-P4S

130

180

24

29,000

39,000

9,500

1.59

HCS71926-E-T-P4S

130

180

24

27,000

36,500

8,000

1.59

HCS7026-C-T-P4S

130

200

33

45,500

58,000

9,000

3.52

HCS7026-E-T-P4S

130

200

33

42,500

54,000

7,500

3.51

nG Greas

m≈kg

CrN

C0rN

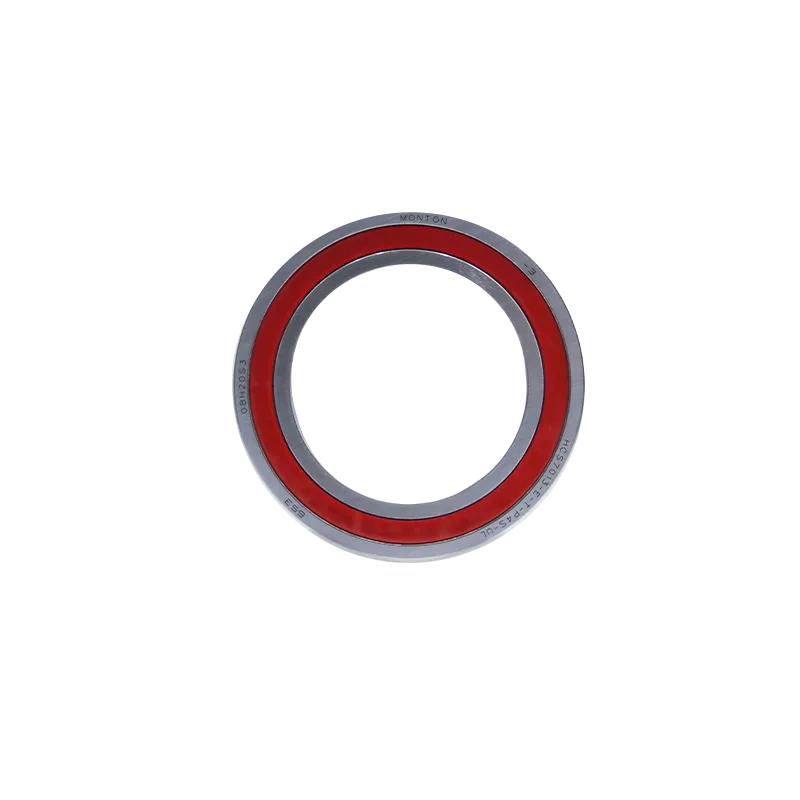

The HCS70XX small ball sealed ceramic ball bearing adopts a non-contact sealing structure that can significantly raise the high-speed performance of the bearing, and can also maintain a stable operating state under high-speed rotation. This feature makes it widely used in high-speed motors, turbochargers and other equipment. This series adopts a pre-lubricated design, and no additional lubrication is required during installation, which simplifies the installation process to a certain extent and improves efficiency. Sealed angular contact ball bearings reduce the possibility of lubricant leakage, greatly reduce maintenance costs, support long-term use in equipment, and reduce the frequency and cost of bearing replacement. Spindle bearings, especially those located at the spindle end, must be effectively sealed.

The non-contact labyrinth seal with dust cover has a compact radial clearance, wide axial clearance and drainage holes, which can effectively isolate cutting fluids, metal chips and dust from the bearing in working and non-working conditions. Sealed grease-lubricated bearings enhance the effect of labyrinth seals and prevent air from flowing in the bearing arrangement. Since the grease life is the bearing life, the appropriate amount of grease and the choice of lubricant are also the key to directly affecting the service life of the machine tool. The sealed bearings have therefore been added with the right amount of high-performance grease.

The widespread application of sealed bearings (ready-to-install, maintenance-free, and lifetime lubrication) has led to the conversion of lubrication from oil lubrication to grease lubrication.Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services, and product technical training on precision bearing information and installation and use. Perfect pre-sales, in-sales, and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products and creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.