Bearing

Balls

d

D

B

6005VV-2RS/P4

Ceramic ball

25

47

12

6205VV-2RS/P4

Ceramic ball

25

52

15

6206VV-2RS/P4

Ceramic ball

30

62

16

6207VV-2RS/P4

Ceramic ball

35

72

17

6210VV-2RS/P4

Ceramic ball

50

90

20

6212VV-2RS/P4

Ceramic ball

60

110

22

6213VV-2RS/P4

Ceramic ball

65

120

23

6325VV-2RS/P4

Ceramic ball

25

62

17

6306VV-2RS/P4

Ceramic ball

30

72

19

6310VV-2RS/P4

Ceramic ball

50

110

27

62205VV-2RS/P4

Ceramic ball

25

52

18

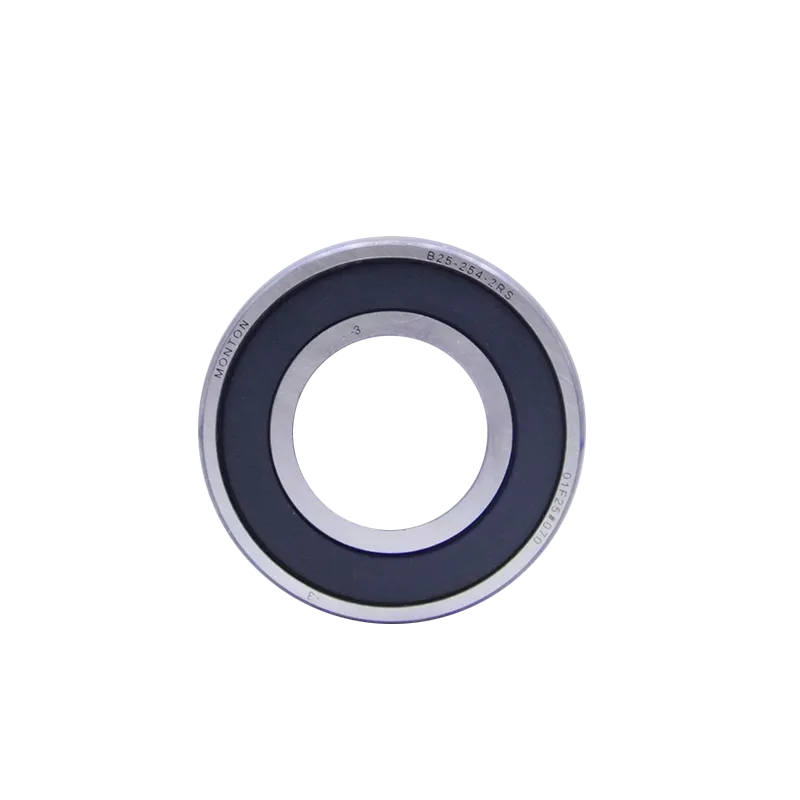

B25-254-2RS/P4

Ceramic ball

25

62

20.6

B25-224-2RS/P4

Ceramic ball

25

62

16

B25-302ZZ-2RS/P4

Ceramic ball

25

62

16

B25-302NXZZ-2RS/P4

Ceramic ball

25

62

16

EPB50-67-2RS/P4

Ceramic ball

50

130

31

EPB60-44-2RS/P4

Ceramic ball

60

130

31

EPB60-47-2RS/P4

Ceramic ball

60

130

31

B40-180-2RS/P4

Ceramic ball

40

90

23

B40-185-2RS/P4

Ceramic ball

40

80

30

B40-188-2RS/P4

Ceramic ball

40

80

18

B40-166-2RS/P4

Ceramic ball

40

90

23

B40-160-2RS/P4

Ceramic ball

30

72

19

F-568217-2RS/P4

Ceramic ball

35

72

23

F-568240-2RS/P4

Ceramic ball

40

80

23

F-568241-2RS/P4

Ceramic ball

40

90

23

F-568241-2RS/P4

Ceramic ball

40

90

23

F-563087-2RS/P4

Ceramic ball

50

90

23

F-563088-2RS/P4

Ceramic ball

50

110

23

F-563091-2RS/P4

Steel ball

60

110

28

F-567384-2RS/P4

Steel ball

50

110

23

F-569109-2RS/P4

Ceramic ball

60

130

28

F-569112-2RS/P4

Ceramic ball

75

130

31

F583269.05-2RS/P4

Ceramic ball

25

72

23

19BSW07

Ceramic ball

19

32

7

B25-83

Ceramic ball

25

58

16

32TM12

Ceramic ball

32

84

15

B27-12B

Ceramic ball

27

82

19

40TM11

Ceramic ball

40

90

19

B27Z-8

Ceramic ball

27.8

78

15

40TM18VZ

Ceramic ball

48

80

16

B28-30

Ceramic ball

28

78

20

60TM04N

Ceramic ball

60

101

17

B28-31

Ceramic ball

28

72

17

65TM02A

Ceramic ball

65

100

17

B28-34

Ceramic ball

28

75

19

B28-31

Ceramic ball

28

72

17

B29-11N

Ceramic ball

29

78

16.5/19

B29-11

Ceramic ball

29

78

18

B29-2NX

Ceramic ball

29

80

18/20

B31-15

Ceramic ball

31

72

9

B30-120

Ceramic ball

30

80

21

B31-16N

Ceramic ball

31

80

16

B30-126

Ceramic ball

30

75

20

B31-26N

Ceramic ball

31

93

21

B31-1

Ceramic ball

31

60

17

B31-26N

Ceramic ball

31

80

16.5

B31-10

Ceramic ball

31

80

16

B32-33

Ceramic ball

32

72

15

B31-13

Ceramic ball

31

93

19

B32Z-6

Ceramic ball

32.5

76

11

B31-15

Ceramic ball

31

72

9

B35-200

Ceramic ball

35

55

9

B31-16A1N

Ceramic ball

31

80

16

B35Z-7

Ceramic ball

35.5

95

12

B31-16N

Ceramic ball

31

80

16

B37-10

Ceramic ball

37

88

18

B31-23N

Ceramic ball

31

94

21

B37-9N

Ceramic ball

37

85

13

B31-28N

Ceramic ball

31

80

16.5/19

B43-3

Ceramic ball

43

73

12

B32-10

Ceramic ball

32

72

19

B43-4

Ceramic ball

43

87

19.5

B32-10/S

Ceramic ball

32

72

19

B45-106N

Ceramic ball

45

90

17

B32-14NR

Ceramic ball

32

80

20

B45-111E

Ceramic ball

45

105

21

B32-18NR

Ceramic ball

32

80

23

B45-90

Ceramic ball

45

100

17.9/21

B32-33

Ceramic ball

32

72

15

B49-5

Ceramic ball

49

95

18

B32-34

Ceramic ball

32

80

10

B49-7

Ceramic ball

49

87

14

B32Z-6

Ceramic ball

32.5

76

11

B57Z-8

Ceramic ball

57.5

80

14

B34Z-5E1

Ceramic ball

34.288

62

14

B60-57

Ceramic ball

60

101

17.2

B33Z-12

Ceramic ball

33.5

76

11

B67-1

Ceramic ball

67

92

13

B35-200

Ceramic ball

35

55

9

B67Z-7

Ceramic ball

57.5

80

12/13.0

B35-221

Ceramic ball

35

72

15

DG328012

Ceramic ball

32.5

80

11.5

B35-27

Ceramic ball

35.5

95

12

DG4880

Ceramic ball

48

80

16

B35Z-7

Ceramic ball

35.5

95

12

B40-121

Ceramic ball

40

72

14

B36Z-10

Ceramic ball

36

67

29

B17-123

Ceramic ball

17

52

21

B37-10

Ceramic ball

37

88

18

B17-126D

Ceramic ball

17

62

17.5

B37-9N

Ceramic ball

37

85

13

B17-127D

Ceramic ball

17

62

20

B37Z-1

Ceramic ball

37.8

68

18

B17-136

Ceramic ball

17

35

10

B39-5

Ceramic ball

39

86

20

B17-29

Ceramic ball

17

52

22

B40-121

Ceramic ball

40

72

14

B17-47D

Ceramic ball

17

47

24

B40-123

Ceramic ball

40

123.2

32

B17-96

Ceramic ball

17

47

18

B40-134N

Ceramic ball

40

100

25

B18Z-1B1

Ceramic ball

18.7

38

10

B40-167A

Ceramic ball

40

90

19

B20-112

Ceramic ball

20

47

14

B43-1

Ceramic ball

43

80

17

B20-122

Ceramic ball

20

47

16

B43-2

Ceramic ball

43

80

17

B20-141

Ceramic ball

20

62

16

B43-8

Ceramic ball

43

87

19.5

B20-151

Ceramic ball

20

52

16

B45-108

Ceramic ball

45

90

17

B20-160

Ceramic ball

20

52

12

B45-130NX2UR

Ceramic ball

45

85

15

B20-161

Ceramic ball

20

52

14

B49-3

Ceramic ball

49

90

19.7

B20-49NR

Ceramic ball

20

55

15

B57Z-7

Ceramic ball

57.7

80

13

B22-19

Ceramic ball

22

62

17

B58-1

Ceramic ball

58

104/108

21

B23-9

Ceramic ball

23

42

7

B60-44

Ceramic ball

60

130

22/31

B24Z-2URN

Ceramic ball

25

63

17

B60-57N

Ceramic ball

60

101

17.2

B25-109

Ceramic ball

25

52

15

B67-1

Ceramic ball

67

92

13

B25-10BC3

Ceramic ball

25

65

17

B67Z-7

Ceramic ball

67.5

80

12.0/13.0

B25-139

Ceramic ball

25

68

18

B75-55NX

Ceramic ball

75

110

18

B25-145

Ceramic ball

25

63

17

B8-75ZZ

Ceramic ball

8

24

10.0/9.0

B25-147

Ceramic ball

25

62

19

BD22-2ENX1

Ceramic ball

22

47

20.6

B25-157

Ceramic ball

25

68

18

BD25-9

Ceramic ball

25

52

23.5

B25-163

Ceramic ball

25

60

19/27

B8-74

Ceramic ball

8

22

11

B25-164ZNXC3

Ceramic ball

25

60

17

BD17-29

Ceramic ball

17

52

22

B25-166

Ceramic ball

25

67

26

BD25-49NX

Ceramic ball

25

60

27

B25-185V

Ceramic ball

25

61

20

BD29-2B

Ceramic ball

29

55

22.5

B25-19

Ceramic ball

25

63

18

BD35-12B

Ceramic ball

35

64

37

B25-198

Ceramic ball

25

63

18

BD35-15

Ceramic ball

35

65

26

B25-214

Ceramic ball

25

62

16

BDZ27-1AUR

Ceramic ball

27

63

33

B25-224

Ceramic ball

25

62

16

BDZ27-2NX

Ceramic ball

27

60

27

B25-238

Ceramic ball

25

68

19

BDZ27-3N

Ceramic ball

27

63

28

B25-238NX

Ceramic ball

25

68

19

BDZ38-1

Ceramic ball

38

68

26

B25-249

Ceramic ball

25

68

19

BDZ45-1

Ceramic ball

45

79

26

B25-254

Ceramic ball

25

52

22

BDZ56-2

Ceramic ball

56

84

23.5/25

B25-63DA2

Ceramic ball

25

63

18

The material of the high-speed motor bearing ring is high-purity bearing steel, combined with special heat treatment process, cold treatment process and material stabilization technology, which greatly improves the fatigue life of this series of bearings. The spindle motor bearing is a deep groove structure, used individually, generally distributed one at the front and rear ends of the motor. The cage adopts a nylon (PEEK) cage guided by rolling elements. The rolling elements adopt imported ceramic balls, which have the characteristics of fast heat dissipation, high temperature resistance, and high-speed operation. The rolling elements adopt imported ceramic balls, which have the characteristics of fast heat dissipation, high temperature resistance, and high-speed operation. Ceramic ball high-speed motor bearings can meet the high speed requirements of the motor. Ceramic ball high-speed motor bearings can also solve the problems of bearing temperature rise and quietness caused by excessive speed. The life of ceramic ball high-speed motor bearings is more than 3 times that of ordinary deep groove ball bearings, and the high-speed performance of the motor is improved by 50%, which can save a lot of costs and improve the reliability and market competitiveness of the product.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and use. Perfect pre-sales, sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable bearing products and creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.