Designation

Dimensions

Basic Loading

Limiting Speed

Weight

Dynamic

Static

nG

nG

d

D

B

Cr

C0r

Grease

Oil

m

mm

mm

mm

kN

kN

min

min

kg

B7000CHQ1

10

26

8

3.0

1.2

100000

160000

0.02

B7001CHQ1

12

28

8

3.3

1.3

85000

130000

0.02

B7002CHQ1

15

32

9

3.6

1.6

75000

110000

0.03

B7003CHQ1

17

35

10

3.9

1.7

67000

100000

0.04

B7004CHQ1

20

42

12

5.7

2.7

56000

85000

0.06

B7005CHQ1

25

47

12

7.4

3.8

45000

67000

0.08

B7006CHQ1

30

55

13

9.1

4.8

38000

56000

0.11

B7007CHQ1

35

62

14

10.9

6.0

34000

53000

0.15

B7008CHQ1

40

68

15

12.9

7.4

32000

48000

0.19

B7009CHQ1

45

75

16

15.0

9.0

30000

45000

0.24

B7010CHQ1

50

80

16

15.9

10.0

26000

43000

0.26

B7011CHQ1

55

90

18

19.9

12.9

22000

38000

0.41

B7012CHQ1

60

95

18

20.4

13.6

21000

36000

0.44

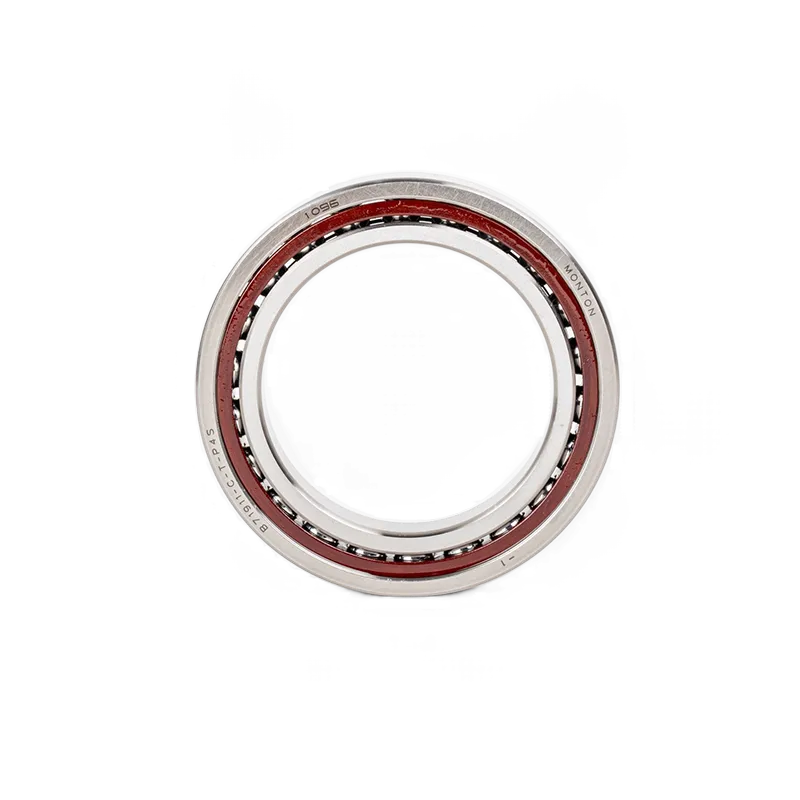

While the CNC machine tool spindle is developing in the direction of high speed and precision, it is required to improve its processing accuracy and production efficiency. The key to realizing these technologies is closely related to high-speed precision bearing technology. At the same time, in order to meet the requirements of high stiffness and low temperature rise of the spindle, the multi-link back-to-back assembly structure of angular contact ball bearings is often used to increase the support span and stiffness of the spindle bearing. In order to achieve more superior performance of the electric spindle, hybrid ceramic ball bearings are widely used in electric spindles. Because of their own special properties, such as the use of silicon nitride ceramic balls for rolling elements and high nitride alloy steel for bearing rings, they are cheap, have low weight and long life. More importantly, the changes to the machine tool mechanism are not significant, and the high degree of standardization also facilitates later maintenance, so this type of bearing is more suitable for high-speed electric spindles. As mentioned in the previous cooling technology, reducing the total friction torque, that is, reducing the friction between the rolling element and the raceway, can control the temperature rise of the bearing, thereby achieving high-speed performance of the spindle, so hybrid ceramic ball bearings are the first choice for realizing this series of technologies. With the development of machine tool technology, the speed of the spindle is getting higher and higher. A key link in achieving high-speed cutting is the development of high-speed precision spindle bearings. Common high-speed rolling bearings have contact angles of 15° and 25°. One is a small steel ball bearing with a reduced steel ball diameter and increased number of steel balls; the other is a small ceramic ball bearing; there are also ceramic ball bearings with the same size as ordinary bearing balls. This type of bearing is only a ceramic ball, and the inner and outer rings are still made of bearing steel, so it is called a hybrid ceramic ball bearing. High-speed electric spindles have very strict and even harsh requirements for their bearing and motor performance. High-speed bearings need to have good rigidity, damping resistance and long service life. There are usually three options: dynamic and static pressure bearings, composite ceramic bearings or electromagnetic suspension bearings. Among them, composite ceramic bearings use hot-pressed ceramic balls and steel bearing rings. Because of their heat resistance and wear resistance, high standardization and easy maintenance, they are most widely used in electric spindle units.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and use. Perfect pre-sales, sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable bearing products and creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.