Ball screw support bearings can meet the application for high precision, high load capacity, high rigidity, low friction, easy installation, maintenance-free or low maintenance screw drive . These applications require safe radial and axial support and extremely precise axial guidance of thespindle.Ball screw support bearings have contact angle of 60°, which can withstand high axial and radial forces. Commonarrangment include DB, DF, DT, etc. This series also have design with two seals, which is convenient for customers to install and use. The main principles for selecting screw drive bearings are axial rigidity, load capacity, running accuracy, speed and friction torque. Other factors that need to be considered are the moment rigidity of the bearing and the ability to adapt to the deflection between the shaft and the bearing seat. Installation and seals also need to be considered.

View Details

76030 ball screw support bearings can meet the requirements of high precision, high load capacity, high rigidity, low friction, easy installation, maintenance-free or low maintenance screw drive applications. These applications require safe radial and axial support and extremely precise axial guidance of the shaft. Ball screw support bearings have a contact angle of 60°. This type of bearing can withstand high axial forces as well as radial forces. Common pairing methods include DB, DF, DT, etc. This series also has a design with a sealing ring device for easy installation and use by customers. The main principles for selecting screw drive bearings are axial rigidity, load capacity, running accuracy, speed and friction torque. Other factors that need to be considered are the moment rigidity of the bearing configuration or the ability to adapt to the deflection between the shaft and the bearing seat. The requirements for installation and sealing also need to be considered.

View Details

BS/TAC Ball screw support bearings are special thrust angular contact ball bearings for supporting the screw shaft of precision ball screws. Support bearings for precision ball screws also have contact seals. Common configurations are DB, DF, DT, etc. The contact angle of support bearings for precision ball screws is designed to be 60°, the steel balls are small in diameter and large in number, and the wall thickness of the inner and outer rings is thicker, which can simultaneously withstand large axial loads and a certain degree of radial loads. This series of products is commonly used in machine tool screw support parts, injection molding machines, and electric injection molding machines.

View Details

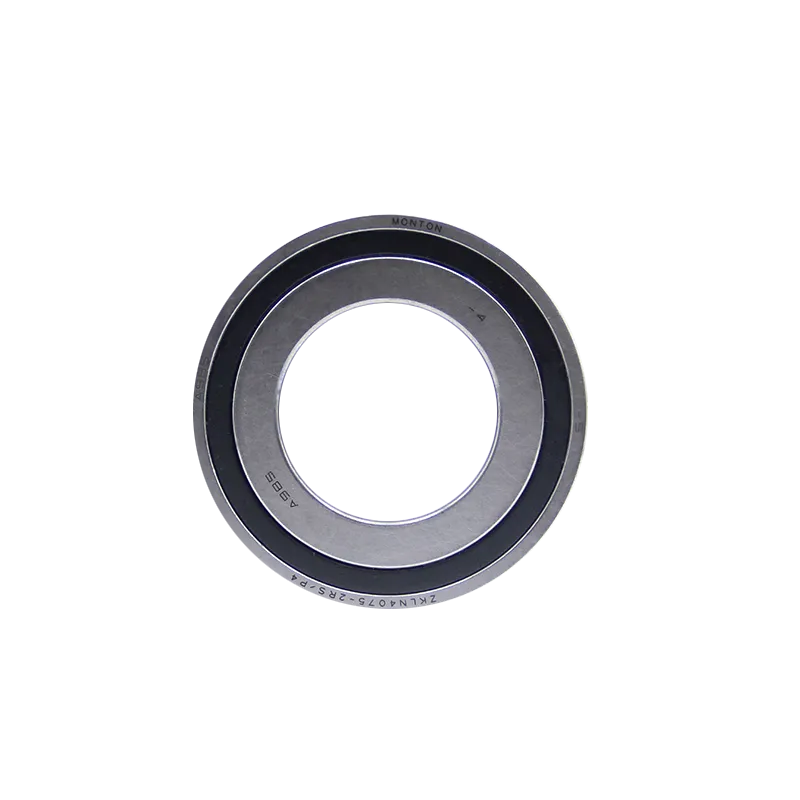

ZKLN screw support bearing is a support bearing with an integrated outer ring and double row thrust angular contact ball structure without mounting holes. This series has four structures: sealed series ZKLN..-2RS, ZKLN..-2Z, ZKLN..-2RS-PE and ZKLN..-2RS-2AP matched bearings. Due to the improvement in raceway accuracy and raceway quality, compared with standard bearings, the contact stress between the rolling elements and the raceway is significantly reduced under the same load. The improvement of quality reduces the friction and temperature rise of the bearing, thereby reducing the operating resistance, reducing the lubrication resistance, extending the life of the grease, and at the same time, under appropriate circumstances, the relubrication cycle is extended. Under low-friction conditions, the efficiency of the bearing arrangement increases simultaneously.

View Details

The ZKLF screw support bearing is a double-row ball with mounting holes. This series has four structures of bearings paired with sealed series ZKLF..-2RS, ZKLF..-2Z, ZKLN..-2RS-PE and ZKLF..-2RS-2AP. The ZKLF screw support bearing is directly mounted on the adjacent structure or in the locating hole by bolts. When installed without radial alignment, the bearing is aligned in the radial direction using the linear guide system and the screw drive as a reference. This prevents misalignment between the screw drive and the bearing position and extends the rated service life of the bearing. A disassembly groove is designed on the circumference of the bearing outer ring to facilitate the removal of the bearing from the locating hole. The radial and axial threaded holes with removable grub screws make the bearing lubrication work simple.

View Details