|

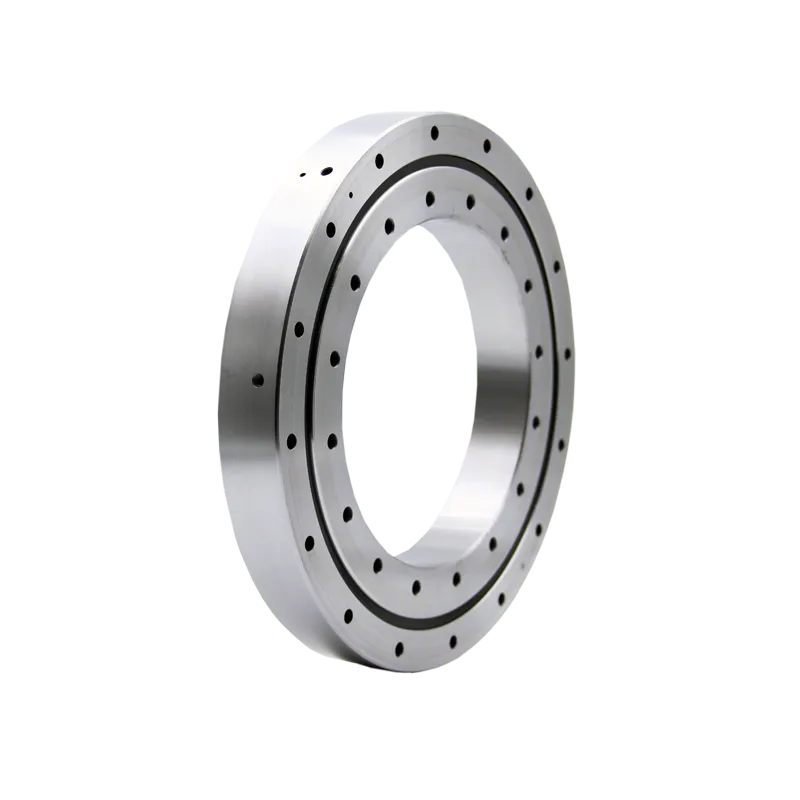

MRW Type Double row crossed roller bearing |

|||||

|

Designation |

Inner ring |

Outer Ring |

Height |

Loading rate |

|

|

d |

D |

B/B1 |

C KN |

Co KN |

|

|

MRW145 |

100 |

185 |

20 |

24.6 |

59.3 |

|

MRW164 |

120 |

210 |

30 |

48.6 |

112 |

|

MRW195 |

150 |

240 |

30 |

54.1 |

136 |

|

MRW228 |

160 |

295 |

35 |

59.3 |

161 |

|

MRW230 |

180 |

280 |

40 |

87 |

215 |

|

MRW250 |

200 |

300 |

40 |

89.7 |

231 |

|

MRW297 |

210 |

380 |

40 |

101 |

288 |

|

MRW323 |

260 |

385 |

50 |

168 |

422 |

|

MRW388 |

325 |

450 |

50 |

199 |

558 |

|

MRW445 |

350 |

540 |

50 |

216 |

652 |

|

MRW463 |

395 |

525 |

50 |

208 |

634 |

|

MRW530 |

460 |

600 |

50 |

233 |

771 |

|

MRW665 |

580 |

750 |

60 |

334 |

1120 |

|

MRW760 |

650 |

870 |

60 |

360 |

1290 |