Low temperature deep groove ball bearings consist stainless steel outer ring, stainless steel inner ring,ceramic(Si3N4) rollers and non-metal cage with self-lubrication, wear resistance and low temperature resistance, that have low friction resistance, high speed, can be used to withstand radial load or radial and axial combined load at the same time, can also be used to withstand axial load, low temperature environment. In the low temperature environment of minus 60 degrees to minus 196 degrees, bearing steel will lose its original strength and toughness due to low temperature makes bearing failure. Therefore, stainless steel bearing steel 9Cr18.9Cr18Mo ceramics and other materials become the first choice because of their excellent low temperature performance. In particular, ceramic materials, not only have extremely high hardness and wear resistance, but also can maintain good thermal stability at extremely low temperatures, which is a ideal materials for low temperature bearings.

View Details

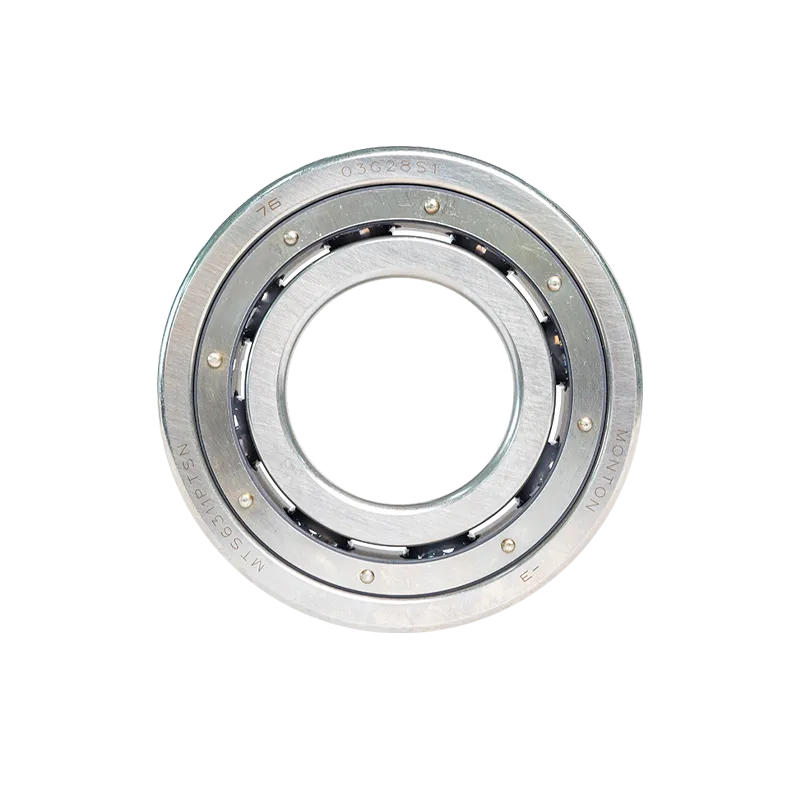

Low temperature angular contact ball bearings areconsist of stainless steel outer rings, stainless steel inner rings, silicon nitride (Si3N4) rolling elements and non-metallic cages that are self-lubricating, wear-resistant and low-temperature resistant. They can withstand radial and axial loads at the same time and can work in low-temperature environments at higher speeds. Low temperature angular contact ball bearings use special materials and structural designs to reduce the friction coefficient, thereby reducing frictional heat, so that the bearings can remain at low temperatures during long-term operation. Ultra-low temperature bearings have an operating temperature below -60 degrees Celsius. The low operating temperature will correspondingly extend the service life of the bearings and improve the bearing performance.

View Details

Cryogenic bearings are one of the key components of cryogenic liquid pumps. Its operating conditions have the following characteristics: the bearings work in a low temperature environment, LNG generally reaches -196℃; there is no lubricant during operation, and the pumping medium is used for lubrication, and the bearing lubrication environment is quite harsh; the working conditions are complex: the conveying medium often contains impurities, is corrosive, and may contain water vapor; high reliability requirements: the downtime maintenance cost is high, and the loss caused by bearing failure is large; for the use of cryogenic bearings, in order to adapt to its requirements under low temperature conditions, the above aspects should be considered during design.

LNG ultra-low temperature bearings are mainly used in cryogenic equipment such as LNG cryogenic submersible pumps. There are two main types of bearings used in cryogenic submersible pumps: deep groove ball bearings and angular contact ball bearings. This type of bearing has been serialized and produced according to international standard model sizes.

View Details