|

Designation |

d |

D |

B |

Loading rate |

Speed |

|

|

6205-H-T35D |

25 |

52 |

15 |

14 |

7.8 |

17000 |

|

6206-H-T35D |

30 |

62 |

16 |

19.3 |

11.2 |

14000 |

|

6207-H-T35D |

35 |

72 |

17 |

25.5 |

15.3 |

12000 |

|

6208-H-T35D |

40 |

80 |

18 |

29 |

18 |

11000 |

|

6209-H-T35D |

45 |

85 |

19 |

31 |

20.4 |

10000 |

|

6210-H-T35D |

50 |

90 |

20 |

36.5 |

24 |

9500 |

|

6211-H-T35D |

55 |

100 |

21 |

43 |

29 |

8500 |

|

6213-H-T35D |

65 |

120 |

23 |

58 |

41.5 |

7000 |

|

6215-H-T35D |

75 |

130 |

25 |

64 |

48 |

6800 |

|

6217-H-T35D |

85 |

150 |

28 |

82.5 |

62 |

6500 |

|

6220-H-T35D |

100 |

180 |

34 |

122 |

93 |

5400 |

|

6222-H-T35D |

110 |

200 |

38 |

144 |

117 |

3000 |

|

6304-H-T35D |

20 |

52 |

15 |

15.2 |

8 |

24000 |

|

6305-H-T35D |

25 |

62 |

17 |

22 |

11 |

22000 |

|

6308-H-T35D |

40 |

90 |

23 |

42.5 |

25 |

11000 |

|

6311-H-T35D |

55 |

120 |

29 |

76 |

47.5 |

10000 |

|

6314-H-T35D |

70 |

150 |

35 |

102 |

66 |

9000 |

|

6318-H-T35D |

90 |

190 |

43 |

132 |

100 |

6000 |

|

6320-H-T35D |

100 |

215 |

47 |

160 |

130 |

5700 |

|

6322-H-T35D |

110 |

240 |

50 |

190 |

165 |

5400 |

|

6328-H-T35D |

140 |

300 |

62 |

255 |

250 |

4000 |

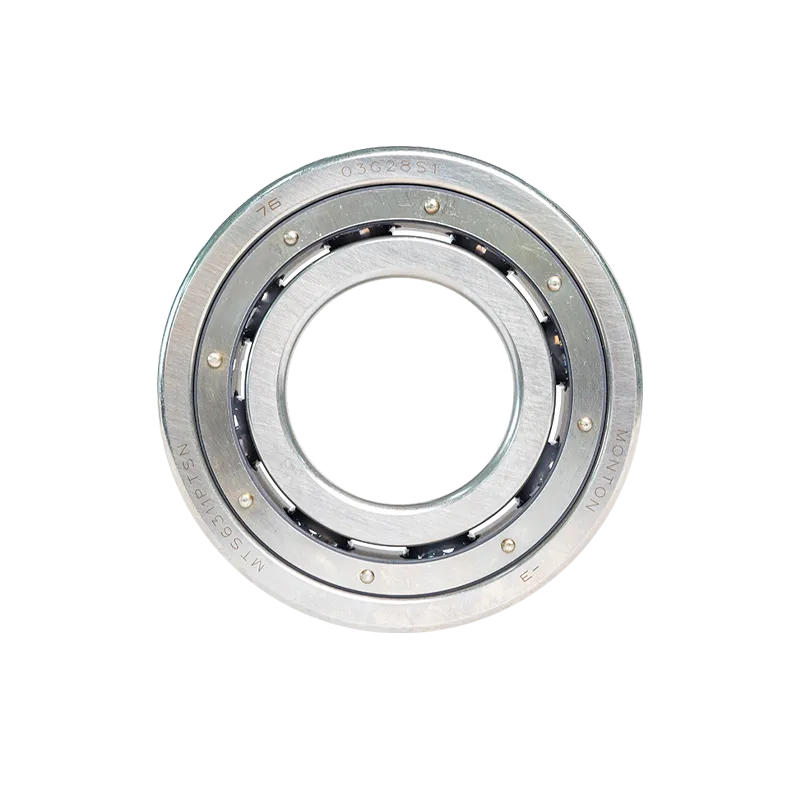

MONTON cryogenic bearings can be used in ultra-low temperature liquid pumps such as liquid oxygen pumps, liquid nitrogen pumps, liquefied gas pumps, liquid pumps for cryogenic equipment, and spacecraft. These ultra-low temperature pumps require bearings with long life, high reliability and can be lubricated with liquid oxygen, liquid nitrogen, liquefied gas and other media; in recent years, with the widespread application of ultra-low temperature pumps, the requirements for long life and working stability of bearings are getting higher and higher. The inner and outer rings of ultra-low temperature bearings are made of high-nitrogen stainless steel, combined with special heat treatment and cold treatment processes; the rolling elements are made of high-performance hot isostatically pressed ceramic balls, and the specially processed raceways with higher precision make the bearings have excellent corrosion resistance, wear resistance and fatigue resistance, and can be lubricated by liquid oxygen, liquid nitrogen, liquefied natural gas, etc., and have amazing performance in high reliability and long life.

MONTON low-temperature bearings are mainly used in low-temperature equipment such as LNG low-temperature submersible pumps. There are two main types of bearings used in low-temperature submersible pumps: deep groove ball bearings and angular contact ball bearings. The bearings work in an ultra-low temperature environment, and there is no lubricant during operation, and they are lubricated by the pumping medium. The bearing lubrication environment is quite harsh, requiring the bearings to have a long life. The bearing ring material is G95Cr18 and G102 Cr Mo stainless steel, or imported high nitrogen stainless steel Cronidur30 (X30 CrMoN15-2) and X.D15N.W (X40 CrMoVN16-2); the rolling element material is G95Cr18 and G102 Cr Mo stainless steel or silicon nitride (Si3N4) or zirconium oxide (ZrO2); the cage is made of non-metallic materials with self-lubrication, wear resistance and low temperature resistance.

Low-temperature bearings have the following characteristics:

1) Strong corrosive environment (suitable for any corrosive medium)

2) Medium lubrication environment (such as bearings immersed in water, water as lubricant, liquid hydrogen or liquid oxygen environment, etc.)

3) No lubrication environment (dry operation)

4) Low operating temperature

5) Anti-magnetic bearings, conductive or non-conductive can be achieved through different coatings.

6) The replacement cycle of ultra-low temperature pump bearings is about 6 times longer than that of conventional bearings;

7) Reduce maintenance and related costs, and reduce unplanned downtime for maintenance;

8) Avoid major pump failures, reduce production losses to a minimum, and extend equipment life;

9) Improve operational safety and reduce secondary damage to pump components;

Main application areas:

Aerospace: Mars probe, satellite probe

Medical equipment: MRI scanner

Chemical process: liquid nitrogen transportation, liquid oxygen storage, etc.

Food processing industry: refrigeration equipment, refrigerated vehicle bearings.

Liquid pumps: cryogenic pumps, LNG pumps, liquefied natural gas pumps, liquid nitrogen (hydrogen, oxygen) pumps, butane pumps, LN2, LO2, LH2, LAr, LNG, CNG, LPG, liquid methane, liquid ethylene, etc. Spacecraft: rocket cryogenic liquid pump, spacecraft liquid pump.

Cryogenic bearings are widely used in aerospace, medical equipment, chemical processes, food processing, liquid pumps and other fields. With the development of science and technology, the application field of cryogenic bearings will continue to expand. At the same time, the manufacturing materials, processes and technologies of cryogenic bearings are also constantly improving to meet more demanding conditions of use.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing data and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.