Mud motor bearing are special bearings that transmit downhole power and torque and bear axial forces in oil screw drilling. This type of bearing is mainly composed of multiple rows of thrust balls and is mainly used for downhole power drilling tools and maintenance. In terms of design and production, the outer diameter of Mud motor bearing can be designed and produced according to user requirements, generally size from Φ50 to Φ290mm. In order to improve the wear resistance, service life, corrosion resistance, impact resistance and load bearing capacity of the bearings, the bearings will use a carbide layer, a supersonic thermal spray layer, and an internal thread and keyway for easy installation and positioning. The material of oil screw drill bearings is usually 55SiMoVa or 8620 carburizing steel, which has high hardness and wear resistance and impact resistance, and can meet the working requirements of complex downhole environments.

View Details

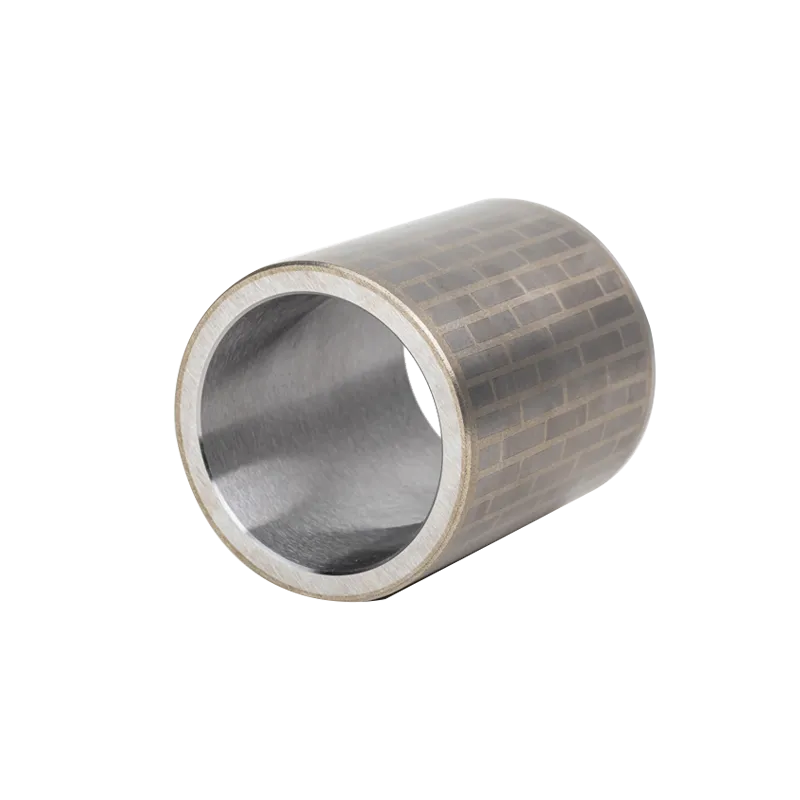

TC bearings are also called Tungsten Carbide Radial Bearing. TC bearings are a key part of oil drilling machinery made of a matrix, tungsten carbide powder and carbide, which are sintered and integrated in a high-temperature furnace and then machined. TC bearings are one of the important parts in screw power drills for oil development and drilling. They mainly bear the radial load generated by the power drill drive shaft during operation. Their quality and performance are directly related to the life of the entire drill. TC bearings are located in the transmission part and are key components that affect the life of screw drills. TC bearings are divided into inner and outer bearing sleeves. The inner sleeve is matched and locked with the drive shaft, and the outer sleeve is assembled with the downhole power drill housing. The two cooperate to form a working surface. The main function is to transmit the torque and speed of the motor to the drill bit.

View Details

Hydrodynamic bearings are special type of oil-lubricated sliding bearings that rely on the dynamic pressure of the liquid in the friction pair to support external loads. The operation of this type of bearing depends on the relative movement between the friction surfaces, allowing the lubricant to enter and maintain the liquid film between the two surfaces. For hydrodynamic bearings, the geometry and surface roughness of the journal and bearing surface are crucial. They muat have a precise shape so that the required liquid film can be formed and maintained during operation. During installation, accurate alignment is also essential to ensure stable operation and extended service life of the bearing.

View Details

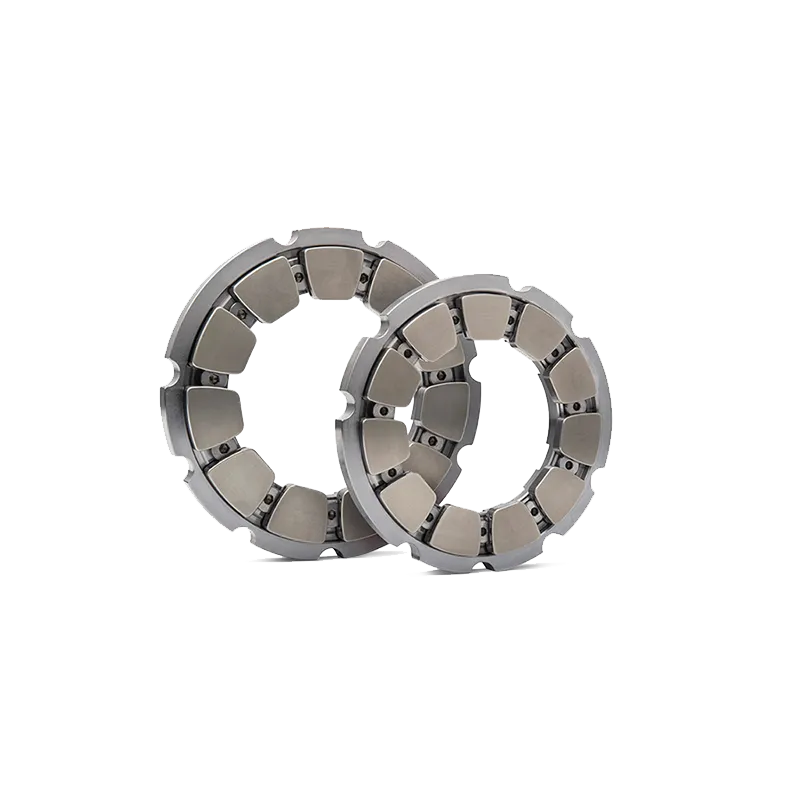

PCD bearings are widely used in turbo drills, mud motor engines and other oilfield applications. PCD bearings are divided into three types: thrust bearings, radial bearings and combined bearings. Compared with tungsten carbide bearings, PCD bearings have a longer service life, which is 4-10 times that of tungsten carbide bearings, while also being able to withstand increased load capacity. We can provide sizes from 1 inch to 10 inches in diameter with excellent product quality.

View Details