Hydrodynamic bearings are widely used in submersible electric pump units, centrifugal blowers, high-speed centrifugal compressors, steam turbines, steam turbine generator sets, etc., aiming to achieve longer reliable operation. Liquid hydrodynamic bearings operate mainly in a non-contact manner. When properly designed and maintained, they will theoretically achieve an unlimited service life.

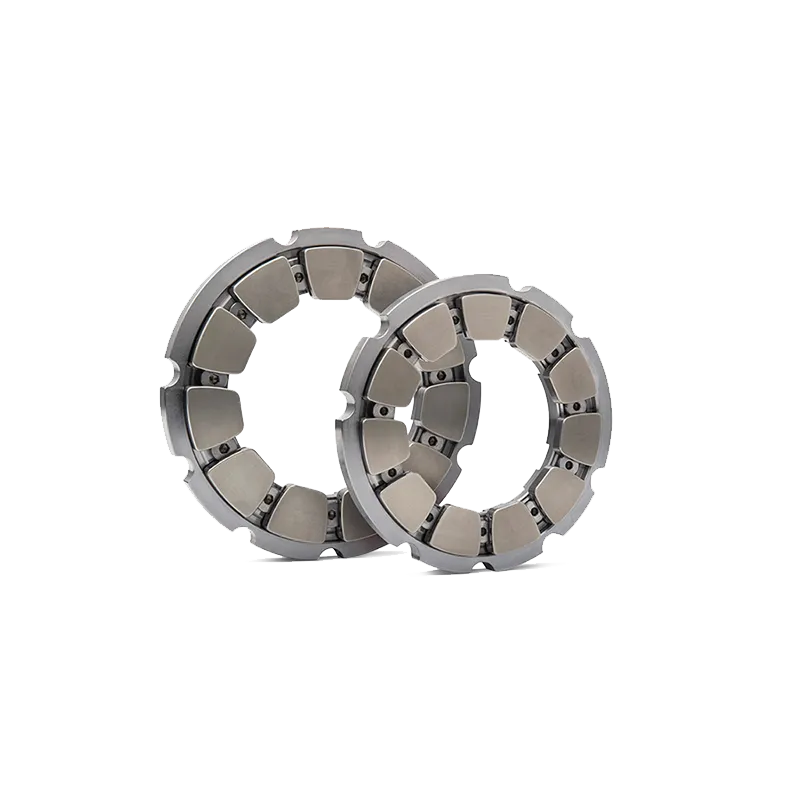

The necessary conditions for hydrodynamic oil film: the two friction pairs must have a certain pressure; the two surfaces must have a certain relative speed so that the large port brings in oil and the small port brings out oil. The two surfaces must be filled with lubricating oil; the two friction pair surfaces must form a wedge shape. Liquid hydrodynamic bearings are divided into radial hydrodynamic bearings and thrust hydrodynamic bearings according to different loads. The radial hydrodynamic bearings have various structures, including three-oil wedge bearings, stepped surface bearings, tilting pad bearings, etc.

Please contact us for more technical information.

Our company has professional sales and technical engineers who are responsible for providing users with precision bearing information and technical consultation, technical services and product technical training on installation and use. Perfect pre-sales, sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable bearing products and creating a good user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.