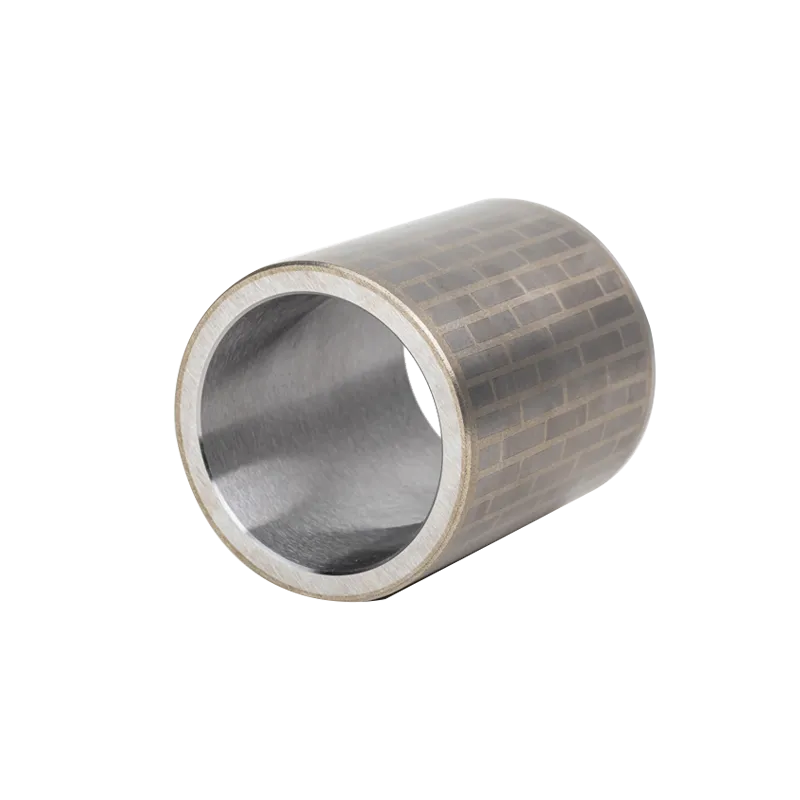

TC bearings are characterized by strong wear resistance, erosion resistance, high hardness, firm bonding between the sintered layer and the steel body, no peeling or falling off, and a service life of more than 300 hours. We can provide all kinds of carbide radial bearings (TC bearings) for all specifications of screw drills.

Features of our bearings:

(1) Our TC bearings adopt the overall sintering process of ordinary high-temperature furnaces and unique sintering formula.

(2) Strictly control the quality of raw materials to ensure that the carbide and tungsten carbide meet the standards and use requirements.

(3) Implement strict sintering production processes to ensure that the sintering process is heated and kept warm in accordance with the set temperature rise curve.

(4) Take advanced protective process measures, the sintered material will not oxidize under high temperature, the surface is purified and activated, the liquid solder is well infiltrated, and the sintered layer shrinks evenly, which not only completely eliminates sintering defects such as shrinkage and pores, but also prevents cracking during the sintering process. The sintered layer is firmly bonded to the matrix and integrated without peeling or falling off.

(5) As the selected cemented carbide has good strength and high hardness, there will be no peeling and cracking problems during use. It is wear-resistant, impact-resistant and corrosion-resistant under harsh working conditions, and its service life can reach more than 300 hours.

(6) The product has exquisite appearance, and the cemented carbide coverage rate is ≥60%. The matrix hardness can be adjusted within the range of 200-330HB as needed.

MONTON generally bearing size:

1. 73mm( 2 7/8")

2. 89mm( 3 1/2")

3. 120mm ( 4 3/4")

4. 165mm (6 1/2")

5. 172mm( 6 3/4")

6. 203mm ( 8")

7. 244mm(9 2/3")

Screw drill is one of the most widely used downhole power tools in oil drilling. TC bearing is located in its transmission part and is a key component affecting the life of screw drill. TC bearing is divided into inner and outer bearing sleeves. The inner sleeve is matched and locked with the transmission shaft, and the outer sleeve is assembled with the downhole power drill housing. The two cooperate to form a working surface. The main function is to transmit the torque and speed of the motor to the drill bit. During the working process, the TC bearing is subjected to axial and radial forces from the universal bearing and the drill bit, and the inner sleeve has an eccentric movement trend around the outer sleeve. The normal failure form of TC bearing is cylindrical layer wear. Due to the long-term erosion of sand-containing well fluid, it is required to have good wear and corrosion resistance.

Our company uses advanced laser technology to combine metallurgy and brazing technology in TC bearings. Tungsten carbide particles are melted on the corrosion-resistant nickel-chromium matrix to form a dense diffusion layer with a porosity of less than 2%. The treatment layer and the metal matrix are metallurgically bonded, with a bonding strength of more than 480 MPa and a thickness of 0. 50 ~ 6. 35 mm, with good resistance to erosion and corrosion, wear and mechanical fatigue.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, creating a good user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.