High-speed wire mill bearings are one of the core components in the production of wire rods and bars. High-speed wire mill bearings, such as the four-row tapered roller bearings used in roughing and medium rolling mills, and the double-row cylindrical roller bearings and angular contact ball bearings used in finishing mills, need to adapt to the environment of high speed and heavy load. Due to the impact loads in the work, the impact toughness of the bearings is very high. High-speed wire mill bearings need to be able to operate stably under high speed, high load and high impact conditions, and have a long fatigue life. Due to its special working conditions, the reliability, wear resistance, service life, impact toughness and other requirements of high-speed wire mill bearings are extremely strict, and the processing difficulty is particularly large. The high-speed wire mill production line requires the use of bearings with stable quality and high reliability due to the special working environment.

View Details

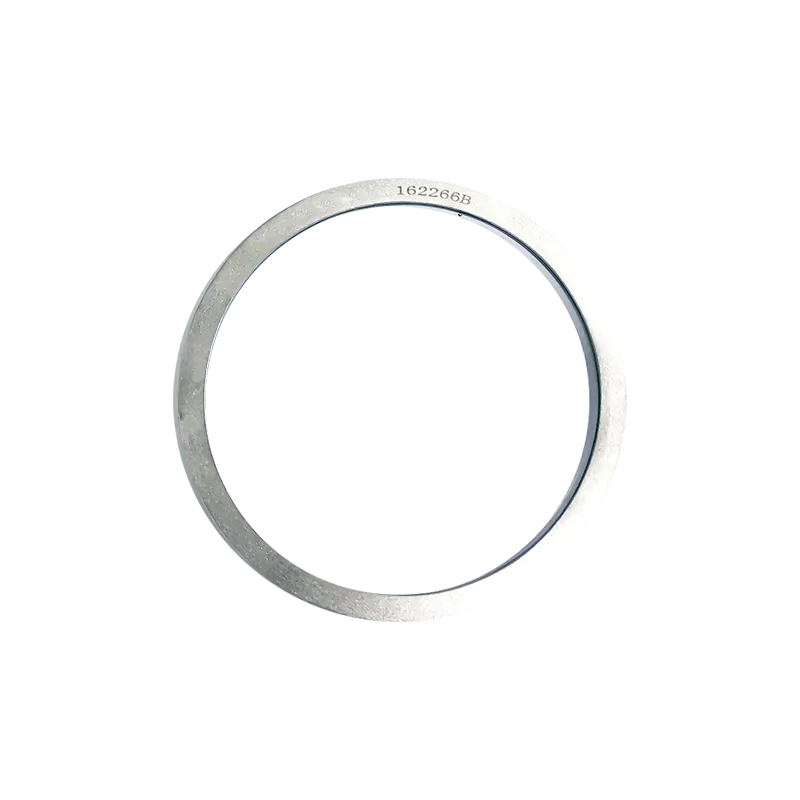

Damping gasketare also called damping washer. High-speed wire mill thrust bearings are equipped with Damping gasket when installed, and preload is required during installation. This Damping gasket can effectively solve the clearance problem of the bearing during operation. If the clearance of bearings too small, they may get stuck or the temperature rises, while if the clearance is too large, it will cause vibration. Adding damping gasket can eliminate vibration and avoid damage to the bearing due to too small clearance, which not only improves the working accuracy of the bearing, but also increases the life of the bearing.

View Details

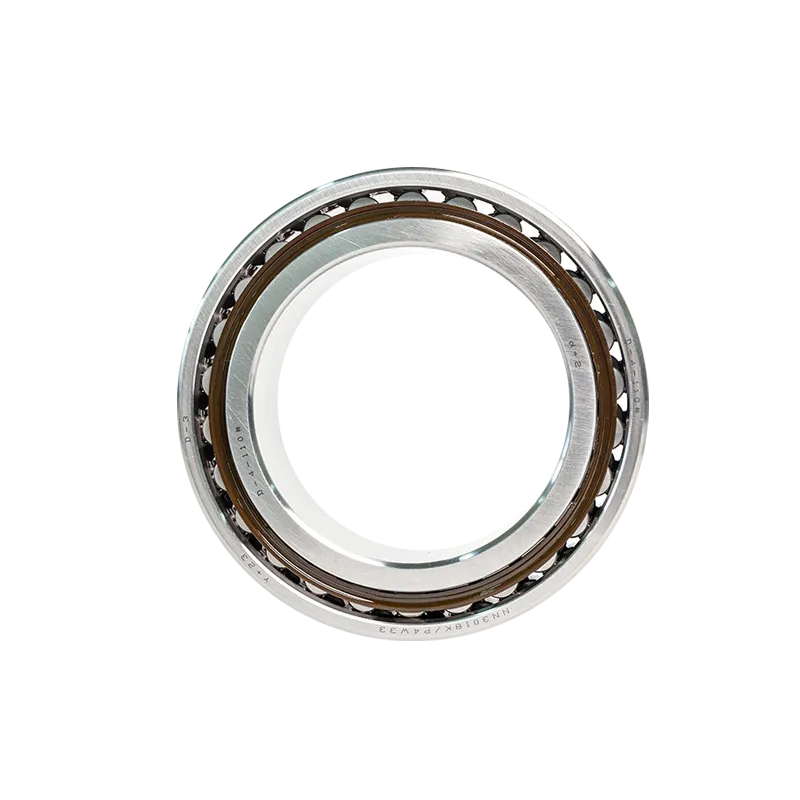

The rollers and raceways of double-row cylindrical roller bearings are in line contact, and the number of rollers arranged is large, so the radial rigidity is high and it is also suitable for high-speed operation. Double-row cylindrical roller bearings are available in two types: NN30 (inner ring with ribs) series and NNU49 (outer ring with ribs) series. The inner diameter of the bearing is available in two types: cylindrical bore and tapered bore (K). The tapered bore bearing can easily obtain the specified radial internal clearance by adjusting the amount of push-in of the bearing on the shaft. Bearings with oil holes and oil grooves in the center of the outer diameter of the outer ring can effectively supply lubricating oil to the inside of the bearing. The general lubrication method for bearings without annular grooves and lubricating oil holes is to fill the minimum amount of grease required, or to use accurately measured oil or oil-air lubrication.

View Details

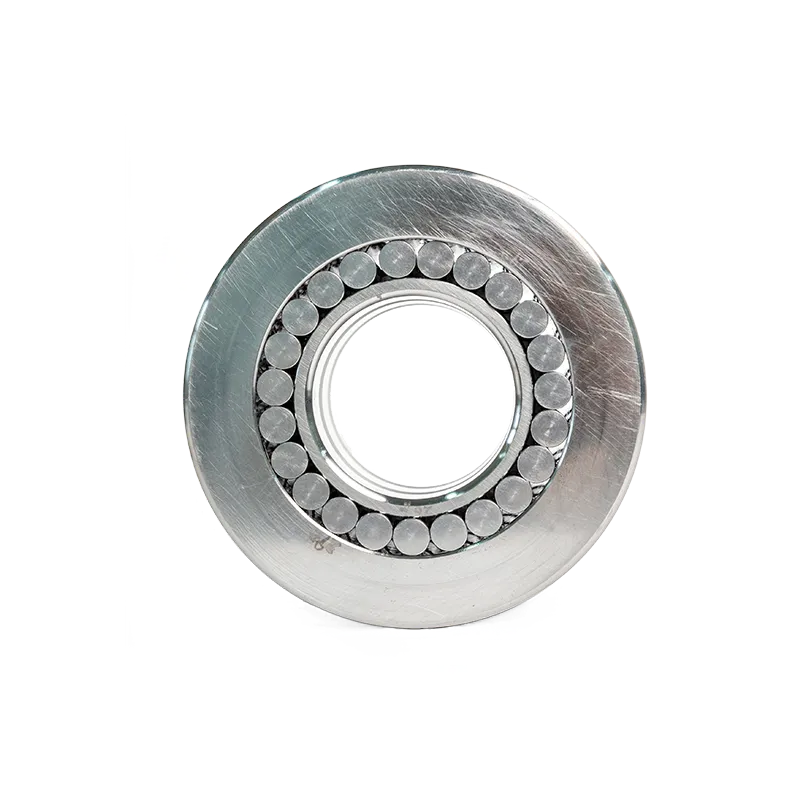

Sendzimir Bearings are also called back up roller bearing. They are used in multi-roll cold rolling mills and can also be used in straightening or bending machines. This type of bearing has a particularly thick outer ring and can be mounted on a fixed support shaft to form a support roll or straightening roll. When used, it is mounted in groups on a stationary shaft to form a support roll. The pressure on the working roll is transmitted to the support roll through the intermediate roll and to the frame through the saddle system. Sendzimir bearings are generally designed with two or three rows of rollers, with cages or full rollers (without cages). Its advantages are simple geometry and high radial load capacity. Backing bearings without flanges or movable retaining rings cannot withstand axial loads by themselves, so this type of bearing must use thrust washers made of copper or engineering plastics, which are installed between the end face of the outer ring and the saddle. This also applies to back up bearings in the form of needle rollers.

View Details

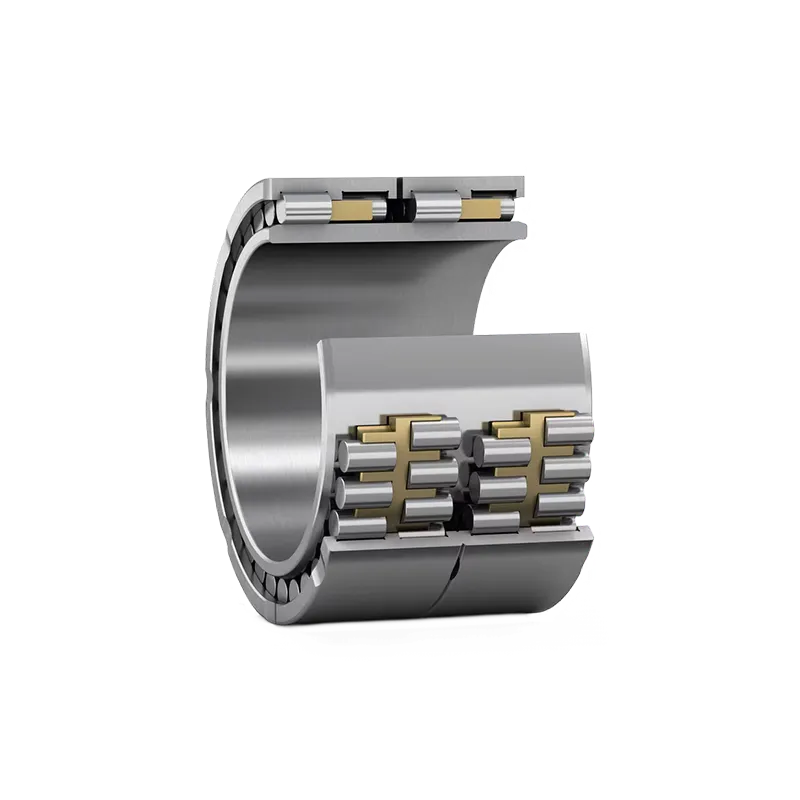

Four-row cylindrical roller bearings are mainly used in roll necks, including support rolls, intermediate rolls and work rolls, rolling stands, calenders and roller presses in plate, long product and section mills. These bearings are usually mounted on the roll neck with an interference fit. Four-row cylindrical roller bearings are well suited for rolling mill applications with high rolling speeds.

Four-row cylindrical roller bearings can only carry radial loads. They are mounted together with deep groove ball bearingor angular contact ball bearings, or with tapered roller bearings that carry axial loads.

View Details

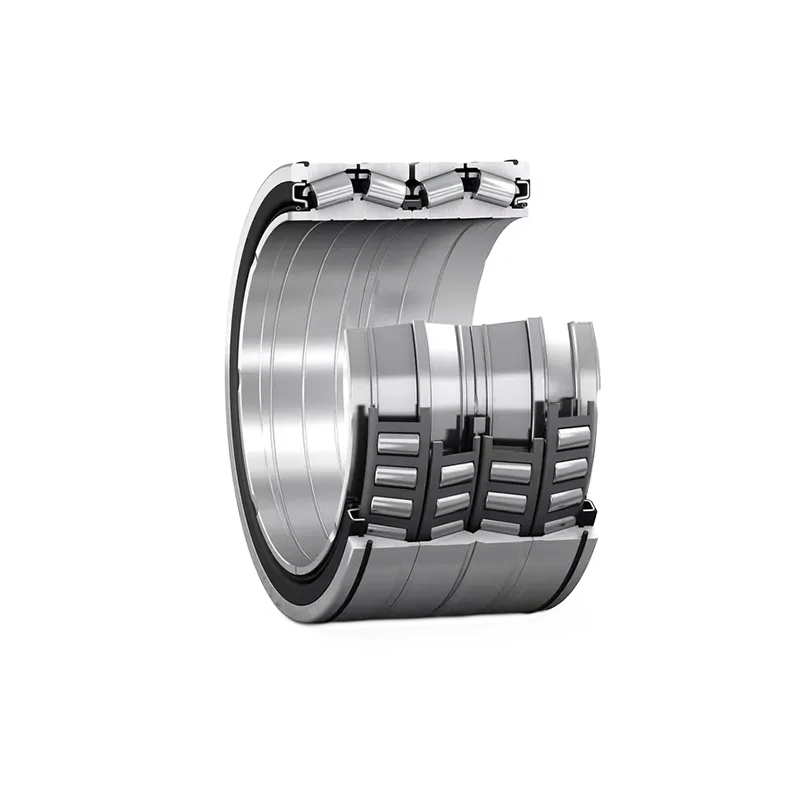

The performance of four-row tapered roller bearings is basically the same as that of double-row tapered roller bearings, but the radial load is greater than that of double-row tapered roller bearings, and the limiting speed is slightly lower. It is mainly used in heavy machinery, rolling mills, etc. Four-row tapered roller bearings are suitable for low-speed and medium-speed rolling mills. The internal clearance of the bearings is pre-adjusted, easy to use, and designed to withstand the maximum rated load in a limited installation space. Four-row tapered roller bearings (open type) are include three outer rings, two inner rings, four rows rollers, two outer spacers, and one inner spacer. Sealed bearings are added with two sealing rings. The clearance of four-row tapered roller bearings can be adjusted with two outer spacers and one inner spacer. This ensures the rotation accuracy and normal operation of the machine parts, and greatly extends the service life of the bearings.

View Details