|

Bearing model |

Dimension |

Basic Load Rating |

Speed Limit |

Radial Stiffness |

Quality |

||||

|

Dynamic Load |

Static Load |

nG Grease |

nG Oil |

c |

|||||

|

d |

D |

B |

Cr N |

C0r N |

min |

min |

N/μm |

m/kg |

|

|

NN3005-AS-K-M-SP |

25 |

47 |

16 |

25.8 |

30 |

20900 |

2500 |

640 |

0.12 |

|

NN3006-AS-K-M-SP |

30 |

55 |

19 |

29000 |

34000 |

16000 |

19000 |

680 |

0.19 |

|

NN3007-AS-K-M-SP |

35 |

62 |

20 |

36000 |

44000 |

14000 |

17000 |

790 |

0.25 |

|

NN3008-AS-K-M-SP |

40 |

68 |

21 |

45000 |

59000 |

12000 |

15000 |

950 |

0.3 |

|

NN3009-AS-K-M-SP |

45 |

75 |

23 |

54000 |

72000 |

11000 |

14000 |

1080 |

0.39 |

|

NN3010-AS-K-M-SP |

50 |

80 |

23 |

57000 |

80000 |

10000 |

13000 |

1180 |

0.43 |

|

NN3011-AS-K-M-SP |

55 |

90 |

26 |

72000 |

100000 |

9000 |

11000 |

1300 |

0.63 |

|

NN3012-AS-K-M-SP |

60 |

95 |

26 |

75000 |

110000 |

8500 |

10000 |

1410 |

0.67 |

|

NN3013-AS-K-M-SP |

65 |

100 |

26 |

77000 |

116000 |

8000 |

9500 |

1470 |

0.72 |

|

NNU4914-S-K-M-SP |

70 |

100 |

30 |

60000 |

104000 |

7500 |

9000 |

1700 |

0.73 |

|

NN3014-AS-K-M-SP |

70 |

110 |

30 |

98000 |

150000 |

7000 |

8500 |

1660 |

1.04 |

|

NNU4915-S-K-M-SP |

75 |

105 |

30 |

63000 |

114000 |

7000 |

8500 |

1870 |

0.77 |

|

NN3015-AS-K-M-SP |

75 |

115 |

30 |

100000 |

156000 |

6700 |

8000 |

1730 |

1.09 |

|

NNU4916-S-K-M-SP |

80 |

110 |

30 |

66000 |

122000 |

6700 |

8000 |

1980 |

0.81 |

|

NN3016-AS-K-M-SP |

80 |

125 |

34 |

120000 |

186000 |

6300 |

7500 |

1850 |

1.51 |

|

NNU4917-S-K-M-SP |

85 |

120 |

35 |

90000 |

166000 |

6300 |

7500 |

2280 |

1.2 |

|

NN3017-AS-K-M-SP |

85 |

130 |

34 |

125000 |

200000 |

6000 |

7000 |

1990 |

1.58 |

|

NNU4918-S-K-M-SP |

90 |

125 |

35 |

93000 |

176000 |

6000 |

7000 |

2420 |

1.26 |

|

NN3018-AS-K-M-SP |

90 |

140 |

37 |

140000 |

224000 |

5600 |

6700 |

2020 |

2.05 |

|

NNU4919-S-K-M-SP |

95 |

130 |

35 |

95000 |

186000 |

5600 |

6700 |

2560 |

1.32 |

|

NN3019-AS-K-M-SP |

95 |

145 |

37 |

143000 |

236000 |

5300 |

6300 |

2100 |

2.14 |

|

NNU4920-S-K-M-SP |

100 |

140 |

40 |

129000 |

255000 |

5300 |

6300 |

3000 |

1.86 |

|

NN3020-AS-K-M-SP |

100 |

150 |

37 |

146000 |

245000 |

5300 |

6300 |

2170 |

2.23 |

|

NNU4921-S-K-M-SP |

105 |

145 |

40 |

129000 |

260000 |

5300 |

6300 |

3080 |

1.93 |

|

NN3021-AS-K-M-SP |

105 |

160 |

41 |

190000 |

310000 |

4800 |

5600 |

2320 |

2.84 |

|

NNU4922-S-K-M-SP |

110 |

150 |

40 |

132000 |

270000 |

5000 |

6000 |

3170 |

2.01 |

|

NN3022-AS-K-M-SP |

110 |

170 |

45 |

220000 |

360000 |

4500 |

5300 |

2500 |

3.61 |

|

NNU4924-S-K-M-SP |

120 |

165 |

45 |

176000 |

340000 |

4500 |

5300 |

3200 |

2.71 |

|

NN3024-AS-K-M-SP |

120 |

180 |

46 |

232000 |

390000 |

4300 |

5000 |

2700 |

3.94 |

|

NNU4926-S-K-M-SP |

130 |

180 |

50 |

190000 |

390000 |

4000 |

4800 |

3600 |

3.73 |

|

NN3026-AS-K-M-SP |

130 |

200 |

52 |

290000 |

500000 |

3800 |

4500 |

2980 |

5.79 |

|

NNU4928-S-K-M-SP |

140 |

190 |

50 |

190000 |

400000 |

3800 |

4500 |

3700 |

4.04 |

|

NN3028-AS-K-M-SP |

140 |

210 |

53 |

300000 |

520000 |

3600 |

4300 |

3090 |

6.22 |

|

NNU4930-S-K-M-SP |

150 |

210 |

60 |

325000 |

655000 |

3600 |

4300 |

4280 |

6.1 |

|

NN3030-AS-K-M-SP |

150 |

225 |

56 |

335000 |

585000 |

3400 |

4000 |

3300 |

7.58 |

|

NNU4932-S-K-M-SP |

160 |

220 |

60 |

335000 |

680000 |

3400 |

4000 |

4420 |

6.41 |

|

NN3032-AS-K-M-SP |

160 |

240 |

60 |

375000 |

670000 |

3200 |

3800 |

3510 |

9.23 |

|

NNU4934-S-K-M-SP |

170 |

230 |

60 |

340000 |

695000 |

3200 |

3800 |

4560 |

6.73 |

|

NN3034-AS-K-M-SP |

170 |

260 |

67 |

450000 |

800000 |

3000 |

3600 |

3770 |

12.5 |

|

NNU4936-S-K-M-SP |

180 |

250 |

69 |

405000 |

850000 |

3000 |

3600 |

5160 |

9.96 |

|

NN3036-AS-K-M-SP |

180 |

280 |

74 |

570000 |

1000000 |

2800 |

3400 |

4040 |

16.4 |

|

NNU4938-S-K-M-SP |

190 |

260 |

69 |

405000 |

880000 |

2800 |

3400 |

5310 |

10.4 |

|

NN3038-AS-K-M-SP |

190 |

290 |

75 |

585000 |

1040000 |

2600 |

3200 |

4190 |

17.3 |

|

NNU4940-S-K-M-SP |

200 |

280 |

80 |

490000 |

1040000 |

2600 |

3200 |

5510 |

14.7 |

|

NN3040-AS-K-M-SP |

200 |

310 |

82 |

655000 |

1200000 |

2400 |

3000 |

4410 |

22.2 |

|

NNU4944-S-K-M-SP |

220 |

300 |

80 |

510000 |

1140000 |

2400 |

3000 |

6000 |

15.9 |

|

NN3044-AS-K-M-SP |

220 |

340 |

90 |

800000 |

1460000 |

2200 |

2800 |

4770 |

29.1 |

|

NNU4948-S-K-M-SP |

240 |

320 |

80 |

530000 |

1200000 |

2200 |

2800 |

6320 |

17.1 |

|

NN3048-AS-K-M-SP |

240 |

360 |

92 |

850000 |

1560000 |

2000 |

2600 |

5140 |

31.6 |

|

NNU4952-S-K-M-SP |

260 |

360 |

100 |

750000 |

1700000 |

2000 |

2600 |

7080 |

29.7 |

|

NN3052-AS-K-M-SP |

260 |

400 |

104 |

1060000 |

2000000 |

1900 |

2400 |

5680 |

46.2 |

|

NNU4956-S-K-M-SP |

280 |

380 |

100 |

765000 |

1800000 |

1900 |

2400 |

7480 |

31.6 |

|

NN3056-AS-K-M-SP |

280 |

420 |

106 |

1080000 |

2080000 |

1800 |

2200 |

5890 |

49.7 |

|

NNU4960-S-K-M-SP |

300 |

420 |

118 |

1040000 |

2400000 |

1700 |

2000 |

8280 |

49.1 |

|

NN3060-AS-K-M-SP |

300 |

460 |

118 |

1270000 |

2400000 |

1600 |

1900 |

5930 |

68.8 |

|

NNU4964-S-K-M-SP |

320 |

440 |

118 |

1060000 |

2550000 |

1600 |

1900 |

8750 |

51.8 |

|

NN3064-AS-K-M-SP |

320 |

480 |

121 |

1320000 |

2600000 |

1600 |

1900 |

6440 |

74.2 |

|

NNU4968-S-K-M-SP |

340 |

460 |

118 |

1100000 |

2650000 |

1500 |

1800 |

9230 |

54.5 |

|

NN3068-AS-K-M-SP |

340 |

520 |

133 |

1630000 |

3250000 |

1400 |

1700 |

7170 |

99.3 |

|

NNU4972-S-K-M-SP |

360 |

480 |

118 |

1140000 |

2800000 |

1500 |

1800 |

9700 |

57.3 |

|

NN3072-AS-K-M-SP |

360 |

540 |

134 |

1660000 |

3350000 |

1400 |

1700 |

7430 |

104 |

|

NNU4976-S-K-M-SP |

380 |

520 |

140 |

1430000 |

3600000 |

1400 |

1700 |

10970 |

85.8 |

|

NN3076-AS-K-M-SP |

380 |

560 |

135 |

1700000 |

3450000 |

1300 |

1600 |

7690 |

110 |

|

NNU4980-S-K-M-SP |

400 |

540 |

140 |

1500000 |

3800000 |

1300 |

1600 |

11540 |

89.4 |

|

NN3080-AS-K-M-SP |

400 |

600 |

148 |

2160000 |

4500000 |

1200 |

1500 |

8660 |

143 |

|

NNU4984-S-K-M-SP |

420 |

560 |

140 |

1530000 |

4000000 |

1300 |

1600 |

12120 |

93.2 |

|

NN3084-AS-K-M-SP |

420 |

620 |

150 |

2120000 |

4500000 |

1200 |

1500 |

8660 |

150 |

|

NNU4988-S-K-M-SP |

440 |

600 |

160 |

2040000 |

5200000 |

1200 |

1500 |

12690 |

129 |

|

NN3088-AS-K-M-SP |

440 |

650 |

157 |

2450000 |

5100000 |

1100 |

1400 |

9240 |

172 |

|

NNU4992-S-K-M-SP |

460 |

620 |

160 |

2120000 |

5500000 |

1100 |

1400 |

13390 |

134 |

|

NN3092-AS-K-M-SP |

460 |

680 |

163 |

2600000 |

5400000 |

1100 |

1400 |

9430 |

197 |

|

NNU4996-S-K-M-SP |

480 |

650 |

170 |

2360000 |

6100000 |

1100 |

1400 |

14110 |

158 |

|

NN3096-AS-K-M-SP |

480 |

700 |

165 |

2700000 |

5850000 |

1000 |

1300 |

10060 |

206 |

|

NNU49/500-S-K-M-SP |

500 |

670 |

170 |

2320000 |

6100000 |

1000 |

1300 |

14110 |

162 |

|

NN30/500-AS-K-M-SP |

500 |

720 |

167 |

2650000 |

5850000 |

1000 |

1300 |

10060 |

214 |

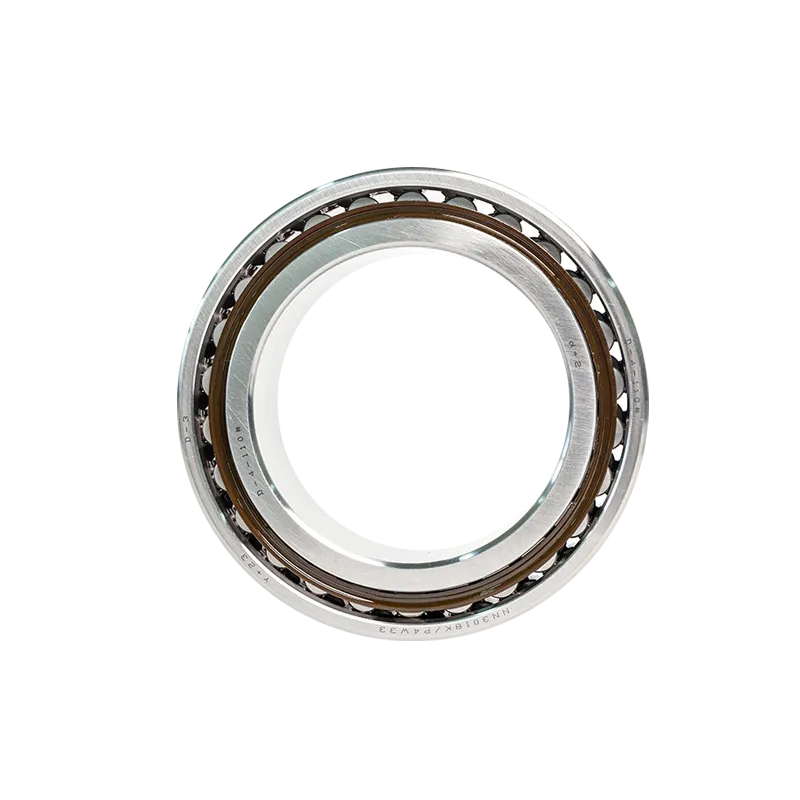

Compared with angular contact ball bearings, double-row cylindrical roller bearings have more advantages in radial stiffness and radial load capacity, and are suitable for lathe spindles with higher stiffness requirements and free-side bearings that bear heavier belt loads. Double-row cylindrical roller bearings can only bear radial loads, and have a larger radial load bearing capacity. In general, double-row cylindrical roller bearings are used when high stiffness is required (mainly lathes). Therefore, this type of bearing is particularly suitable for machine tool spindles that must bear heavy radial loads, high speeds, and have higher stiffness. Bearings with a 1:12 tapered bore (code suffix K) are superior to cylindrical bore bearings because the tapered surface can accurately adjust the clearance and preload during installation. NN30 series bearings can provide a unique balance between load capacity, rigidity and speed, and are therefore generally used as drive-end bearings for machine tool spindles. The inner ring of the NN30 series bearings has three integral ribs, while the outer ring has no ribs. The cross-sectional height of the NNU49 series bearings is very low. This design has higher stiffness than the NN30 series bearings, but slightly lower load capacity. The outer ring of the NN49 series bearing has three integral flanges, while the inner ring has no flanges.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing data and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, creating excellent user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.