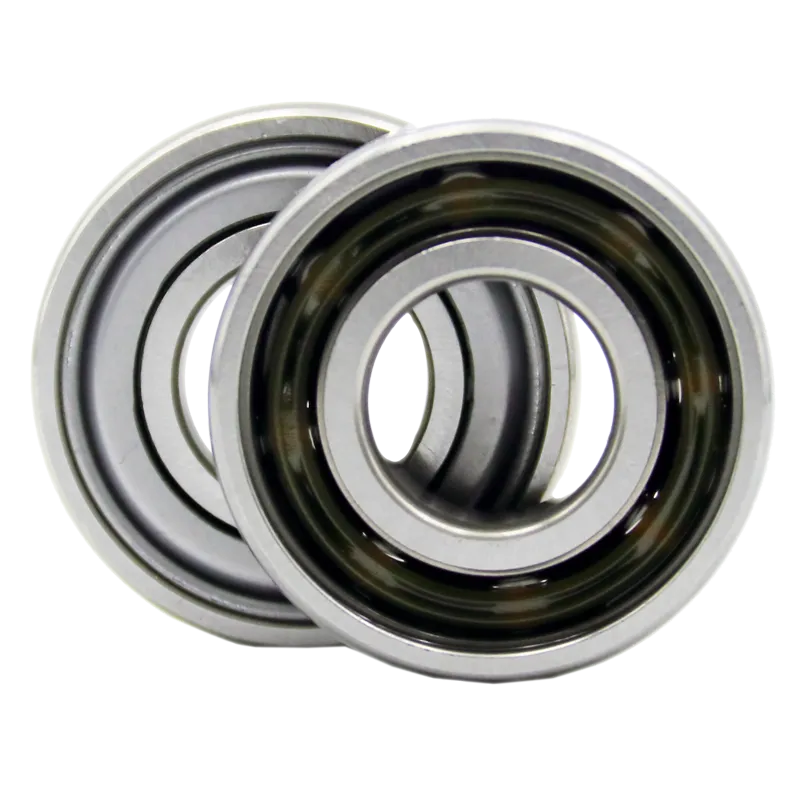

The high-speed wire rod rolling mill guide bearing produced by MONON adopts a deep groove ball bearing structure, which has high precision, high speed, and high reliability. The precision of the high-speed wire guide bearing provided by our company reaches P5 level. The cage adopts a nylon pocket hole structure shape, with one side sealed and low operating noise. It can run at a speed of up to 100 meters per second when used on the high-speed wire guide wheel in the steel rolling mill. The high-speed wire guide bearing designed by MONON has a thermal barrier layer on the outer diameter and end face of the outer ring. The guide bearing with the thermal barrier layer can improve the insulation performance of the bearing, enhance the sealing of the bearing, and enable the bearing to be used on the guide wheel for wire and steel pipe rolling.

Guide wheels are widely used in the rolling process of wire and steel pipes, and their shape matches the shape of the steel. In the process of wire rolling, guide wheels mainly guide the rolled steel forward, playing a role in straightening and guiding. The speed of guide wheels is generally between 20000-3000 RPM. The temperature of the rolled steel is high, and coupled with pollution such as cooling water and oxide skin, bearings work in high-speed, high-temperature, and polluted environments. Traditional sealed deep groove ball bearings work in such poor working conditions, shorten their service life, and cause losses such as equipment shutdown. MONON Bearing has made technological improvements to the high wire guide bearing in the steel rolling mill, fundamentally enhancing the bearing's insulation performance, improving the sealing structure, and enabling the steel rolling wire guide deep groove ball bearing to be applied precisely to the guide wheel.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and application. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating excellent user experience and rich benefits for every user.

If you have any questions about products and services, please contact the company's service department directly.