|

Bearing NO. |

Boundary Dimensions |

Maximum Radial Load (KN) |

Weight |

||||

|

d |

D |

B |

C |

Dynamic |

Static |

Kg |

|

|

BNPF102256/2RZ |

50 |

110 |

56 |

55 |

96 |

136 |

2.9 |

|

BNUP112452 |

55 |

120 |

52 |

51.2 |

104 |

149 |

3.4 |

|

BNUPA112452 |

55 |

120 |

52 |

51.2 |

86 |

122 |

3.5 |

|

BKBF112452 |

55 |

120 |

52.2 |

52 |

166 |

235 |

3.5 |

|

BNNB112460/BH1 |

55 |

120 |

60 |

60 |

159 |

227 |

3.8 |

|

BNUP112464 |

55 |

120 |

64 |

63.2 |

130 |

185 |

4.2 |

|

BNNB123374 |

60 |

165 |

74 |

74 |

306 |

437 |

10 |

|

BNBA133370 |

65 |

165 |

70 |

70 |

185 |

264 |

9.5 |

|

BNUP143275 |

70 |

160 |

75 |

74.2 |

160 |

230 |

9 |

|

BNUP143290/2RZ |

70 |

160 |

90 |

89.2 |

220 |

320 |

10 |

|

BNPF143290/2RZ |

70 |

160 |

90 |

89.2 |

240 |

340 |

10.5 |

|

BNTB143290/IS |

70 |

160.02 |

90 |

90 |

330 |

480 |

10 |

|

BNTF143290/IS |

70 |

160.02 |

90 |

90 |

350 |

510 |

10.5 |

|

BNTF143290 |

70 |

160.02 |

90 |

90 |

350 |

510 |

10.5 |

|

NNCF143290V |

70 |

160 |

90 |

90 |

350 |

510 |

10.6 |

|

BNBA184494 |

90 |

220 |

94 |

94 |

310 |

440 |

21.5 |

|

BNAF184494 |

90 |

220 |

94 |

94 |

325 |

465 |

21 |

|

BNTBP1844120 |

90 |

220 |

120 |

120 |

390 |

555 |

26.5 |

|

BNTPF1844120 |

90 |

220 |

120 |

120 |

410 |

590 |

27 |

|

BNTF1844120 |

90 |

220.02 |

120 |

120 |

510 |

720 |

27.5 |

|

BNUP204596 |

100 |

225 |

96 |

95.2 |

350 |

500 |

22.5 |

|

BNUP2045120/2RZ |

100 |

225 |

120 |

119 |

370 |

520 |

28 |

|

BNPF2045120/2RZ |

100 |

225 |

120 |

119 |

390 |

550 |

28 |

|

BNUP2045120/BH1 |

100 |

225 |

120 |

119 |

370 |

520 |

28 |

|

BNPF2045120/BH1 |

100 |

225 |

120 |

119 |

390 |

550 |

28 |

|

BNTB2045120/IS |

100 |

225 |

120 |

120 |

600 |

860 |

24.5 |

|

BNTF2045120 |

100 |

225 |

120 |

120 |

630 |

890 |

28 |

|

BNFP2045120 |

100 |

225 |

120 |

120 |

630 |

890 |

28 |

|

BNUP2045126 |

100 |

225 |

126 |

119 |

370 |

520 |

28 |

|

NNCF2045130 |

100 |

225 |

130 |

130 |

600 |

850 |

32 |

|

NNCF224690 |

110 |

230 |

90 |

90 |

490 |

640 |

22 |

|

NNCF2246110 |

110 |

230 |

110 |

110 |

580 |

860 |

30 |

|

NNCF2246120 |

110 |

230 |

120 |

120 |

630 |

890 |

32 |

|

BNBA225298 |

110 |

260 |

98 |

98 |

310 |

440 |

31 |

|

BNPBF2252110 |

110 |

260 |

110 |

110 |

470 |

670 |

35 |

|

BNBA2252125 |

110 |

260 |

125 |

125 |

390 |

560 |

40 |

|

NNCF2260108 |

110 |

300 |

108 |

108 |

530 |

560 |

48 |

|

NNCF2452125 |

120 |

260 |

125 |

125 |

420 |

900 |

40 |

|

BNTB2452125 |

120 |

260 |

125 |

125 |

410 |

850 |

40 |

|

BNUP2452160 |

120 |

260 |

160 |

160 |

1000 |

1200 |

50 |

|

BNUP2660150 |

130 |

300.02 |

150 |

149 |

890 |

1280 |

61.5 |

|

BNUPA2660160 |

130 |

300.02 |

160 |

159.5 |

610 |

870 |

64.5 |

|

BNTF2660160 |

130 |

300.02 |

160 |

160 |

795 |

1130 |

65.5 |

|

NNCF2660168 - 2RS |

130 |

300.02 |

170 |

168 |

795 |

1130 |

70 |

|

BNUP2660172 |

130 |

300.02 |

172.6 |

171.6 |

830 |

1180 |

68 |

|

BNTB2660172 |

130 |

300.02 |

172.6 |

172.6 |

790 |

1120 |

72.5 |

|

BNTF2660172 |

130 |

300.02 |

172.6 |

172.6 |

820 |

1160 |

71.5 |

|

BNUP2660172/2RZ |

130 |

300.02 |

172.6 |

171.6 |

620 |

890 |

70 |

|

BNUP2660172 |

130 |

300.02 |

172.6 |

171.6 |

620 |

890 |

70 |

|

NNCF3680170P4 |

180 |

406.42 |

170 |

170 |

1290 |

1840 |

130 |

|

NNCF3680170P4Y |

180 |

406.42 |

170 |

170 |

920 |

1310 |

130 |

|

NNCF3680224 |

180 |

406.42 |

224 |

224 |

1150 |

1620 |

170 |

|

NNCF3680224Y |

180 |

406.42 |

224 |

224 |

1150 |

1620 |

170 |

|

BNUP3681171 |

180 |

406.42 |

171 |

170 |

890 |

1270 |

130 |

|

BNUP3681224/2RZ |

180 |

406.42 |

224 |

223 |

1150 |

1620 |

170 |

|

BNUP3681224/BH1 |

180 |

406.42 |

224 |

223 |

1150 |

1620 |

170 |

|

BNTPA3681171 |

180 |

406.42 |

171 |

170 |

1070 |

1530 |

130 |

|

BNTB3681171/IS |

180 |

406.42 |

171 |

171 |

1290 |

1840 |

130 |

|

BNTF3681171/BH1 |

180 |

406.42 |

171 |

171 |

920 |

1310 |

130 |

|

NNCF3681182 - 2RS |

180 |

406.42 |

182 |

179 |

920 |

1310 |

135 |

|

BNTB3681217 |

180 |

406.42 |

217 |

217 |

1490 |

2110 |

165 |

|

BNTB3681224 |

180 |

406.42 |

224 |

224 |

1530 |

2170 |

170 |

|

BNTB3681224/BH2 |

180 |

406.42 |

224 |

224 |

1530 |

2170 |

170 |

|

BNTB4092171 |

200 |

460 |

171 |

170 |

1310 |

1860 |

166 |

|

BNUP4092241 |

200 |

460 |

241 |

240 |

1790 |

2540 |

239 |

|

06DC0846A |

31.75 |

76.2 |

46.23 |

45.85 |

121 |

183 |

1.27 |

|

11N1226V |

54.999 |

120 |

25.999 |

25.999 |

99.3 |

138 |

1.69 |

|

11DC1252 |

55 |

120 |

52.197 |

52 |

254 |

341 |

3.27 |

|

14DC1690LDS-1 |

70 |

160 |

90 |

90 |

434 |

546 |

10.1 |

|

14DC1690ADS |

70 |

160.07 |

90 |

90 |

475 |

667 |

10.5 |

|

18DC19100NDS |

90 |

190 |

100 |

100 |

593 |

770 |

14.7 |

|

20DC23080DS |

100 |

225.021 |

80 |

80 |

759 |

991 |

18.2 |

|

20DC23120MDS |

100 |

225.021 |

120 |

120 |

1020 |

1440 |

27.2 |

|

20DC23100NDS-1 |

100 |

225 |

100 |

100 |

683 |

838 |

21.7 |

|

20DC23120KDS-2 |

99.995 |

225 |

120 |

120 |

780 |

995 |

26 |

|

26DC30160DS |

130 |

300 |

160 |

159.5 |

1660 |

2340 |

64.8 |

|

26DC30170MDS |

130 |

300 |

172.644 |

172.644 |

1950 |

2900 |

72.6 |

|

26DC30170KDS-3 |

130 |

300 |

172.644 |

172.644 |

1650 |

2210 |

70 |

|

36DC41171DS |

180 |

406.42 |

171.04 |

171.04 |

2580 |

3810 |

130 |

|

36DC41171ADS |

180 |

406.42 |

171.04 |

171.04 |

2390 |

3340 |

124 |

|

36DC41171KDS |

180 |

406.42 |

171.04 |

171.04 |

2090 |

2960 |

125 |

|

36DC41217DS+DP |

179.984 |

406.43 |

223.96 |

217 |

2940 |

4500 |

161 |

|

36DC41224KDS |

179.984 |

406.43 |

224.25 |

220 |

2430 |

3530 |

160 |

|

36DC41224QDS |

180 |

406.42 |

224.25 |

224 |

2860 |

4230 |

162 |

|

10NUP1144 |

50 |

110 |

44.4 |

44.4 |

158 |

167 |

2.33 |

|

10NUP1346/48 |

50 |

125 |

48 |

46 |

202 |

213 |

3.39 |

|

10NUP1352 |

50 |

125 |

52 |

52 |

226 |

256 |

3.8 |

|

10DC1280DS |

50 |

120 |

80 |

80 |

335 |

379 |

5.15 |

|

10DC1285DS |

50 |

120 |

85 |

85 |

379 |

427 |

5.4 |

|

12DC1695DS |

60 |

160 |

95 |

95 |

498 |

589 |

11.5 |

|

13DC17100DS |

65 |

170 |

100 |

100 |

498 |

597 |

13.5 |

|

18DC23100DS |

90 |

230 |

100 |

100 |

802 |

982 |

24.2 |

|

20DC2695DS |

100 |

260 |

95 |

95 |

871 |

1060 |

30.2 |

|

20DC26105DS |

100 |

260 |

105 |

105 |

975 |

787 |

33.5 |

|

18DC26125DS |

90 |

260 |

125 |

125 |

1150 |

1520 |

41.3 |

|

20DC26130DS |

100 |

260 |

130 |

130 |

1190 |

1580 |

41.5 |

|

22DC28165DS |

110 |

280 |

165 |

165 |

1390 |

1880 |

60.2 |

|

24DC28165DS |

120 |

280 |

165 |

165 |

1380 |

1940 |

57.7 |

|

24DC35165ADS |

120 |

350 |

165 |

165 |

1710 |

2220 |

98.3 |

|

26DC35175DS |

130 |

350 |

175 |

175 |

1750 |

2300 |

101 |

|

12DC1690DS |

62 |

155 |

90 |

90 |

445 |

529 |

9.97 |

|

12DC16110DS |

62 |

155 |

110 |

110 |

505 |

622 |

12.2 |

|

18DC2295DS |

90 |

220 |

95 |

95 |

664 |

795 |

20.9 |

|

18DC22130ADS |

90 |

220 |

130 |

130 |

873 |

1130 |

28.7 |

|

23DC26140DS |

115 |

260 |

140 |

140 |

1220 |

1690 |

41.9 |

|

13DC1770DS |

65 |

165 |

70 |

70 |

531 |

586 |

8.83 |

|

18DC2294DS |

90 |

220 |

94 |

94 |

860 |

997 |

21.2 |

|

18DC2294/96DS |

90 |

220 |

96 |

94 |

618 |

700 |

21 |

|

26DC30130DS |

130 |

300.02 |

130 |

129 |

1300 |

1740 |

52.2 |

|

26DC30130BDS |

130 |

300.02 |

130 |

129 |

1340 |

1620 |

51.8 |

|

26DC30132ADS |

130 |

300.02 |

132 |

129 |

1430 |

1830 |

53.8 |

|

WGTR 25x55x31,2 2 |

25 |

55 |

31,2 |

30,5 |

30 |

42 |

0,4 |

|

WGTR 35x80x40 |

35 |

80 |

40 |

39,2 |

69 |

103 |

1,2 |

|

F-82547 |

45 |

125 |

78 |

77,5 |

225 |

325 |

5,6 |

|

WGTR 55x120x52 |

55 |

120 |

52 |

51,2 |

123 |

218 |

3,4 |

|

WGTR 55x120x64 |

55 |

120 |

64 |

63,2 |

155 |

300 |

4,2 |

|

F-560123.01 |

55 |

126,02 |

64 |

63 |

163 |

295 |

4,6 |

|

F-566100.01 |

60 |

150 |

75 |

73 |

222 |

335 |

7,9 |

|

WGTR 70x160x75 |

70 |

160 |

75 |

74,2 |

231 |

380 |

8,9 |

|

WGTR 70x160x90 |

70 |

160 |

90 |

89,2 |

300 |

550 |

10,7 |

|

F-566567.01 |

70 |

165 |

90 |

88 |

310 |

560 |

10,7 |

|

F-565718.01 |

70,02 |

160 |

90 |

89 |

300 |

550 |

10,7 |

|

Z-540268.02.WGTR |

70 |

160,02 |

90 |

90 |

650 |

285 |

11,4 |

|

Z-541332.01.WGTR |

90 |

220,02 |

94 |

94 |

455 |

870 |

21 |

|

Z-541332.02.WGTR |

90 |

220,02 |

94 |

94 |

530 |

1100 |

21 |

|

F-801941.WGTR |

90 |

220,02 |

96 |

94 |

415 |

780 |

22,2 |

|

Z-567709.01.WGTR |

90 |

220,02 |

96 |

94 |

360 |

630 |

20 |

|

F-808398.WGTR |

90 |

220,02 |

120 |

120 |

485 |

1120 |

28.5 |

|

Z-517329.01.WGTR |

90 |

220,02 |

120 |

120 |

540 |

1500 |

28.6 |

|

F-550356.01.WGTR |

90 |

220,02 |

122 |

119 |

530 |

1030 |

27,1 |

|

F-801644.02.WGTR |

100 |

225 |

120 |

119 |

560 |

1310 |

26 |

|

F-801644.03.WGTR |

100 |

225 |

120 |

119 |

485 |

1050 |

26 |

|

Z-566148.WGTR |

100 |

225 |

120 |

119 |

520 |

1170 |

26 |

|

Z-543638.02.WGTR |

100 |

225 |

120 |

120 |

530 |

1380 |

27,7 |

|

Z-575633.WGTR |

110 |

260 |

98 |

98 |

510 |

1010 |

31,9 |

|

Z-577888.WGTR |

130 |

300,02 |

130 |

129 |

760 |

1560 |

54,9 |

|

Z-578270.01.WGTR |

130 |

300,02 |

132 |

129 |

760 |

1560 |

56,5 |

|

Z-564604.WGTR |

130 |

300,02 |

150 |

149 |

890 |

1860 |

60 |

|

Z-548963.WGTR |

130 |

300,02 |

161,5 |

160,5 |

910 |

1880 |

67,4 |

|

Z-567455.01.WGTR |

130 |

300,02 |

172,65 |

171,6 |

1010 |

2370 |

71,3 |

|

Z-567998.01.WGTR |

130 |

300,02 |

172,65 |

171,6 |

1010 |

2370 |

73,5 |

|

Z-549722.WGTR |

130 |

300,02 |

172,65 |

171,6 |

1010 |

2370 |

73,6 |

|

Z-549722.01.WGTR |

130 |

300,02 |

172,65 |

171,6 |

1010 |

2370 |

73,6 |

|

Z-512497.03.WGTR |

130 |

300,02 |

172,64 |

172,6 |

1030 |

2700 |

74,8 |

|

Z-564247.WGTR |

180 |

406,4 |

171,04 |

170 |

1250 |

3000 |

125 |

|

Z-564247.02.WGTR |

180 |

406,4 |

171,04 |

170 |

1250 |

3000 |

125 |

|

F-804209.WGTR |

180 |

406,4 |

224 |

220 |

1420 |

3450 |

174 |

|

F-800115.01.WGTR |

180 |

406,42 |

171,04 |

170 |

1170 |

2650 |

132 |

|

Z-527502.03.WGTR |

180 |

406,42 |

171,04 |

171 |

1420 |

3850 |

130 |

|

Z-543307.01.WGTR |

180 |

406,42 |

171,04 |

171 |

1420 |

3850 |

130 |

|

F-809717.WGTR |

180 |

406,42 |

176 |

170 |

1250 |

3000 |

136 |

|

Z-514278.01.WGTR |

180 |

406,42 |

217 |

217 |

1720 |

4900 |

150 |

|

Z-523247.02.WGTR |

180 |

406,42 |

224 |

224 |

1790 |

5100 |

169 |

|

Z-523247.03.WGTR |

180 |

406,42 |

224 |

224 |

1790 |

5100 |

169 |

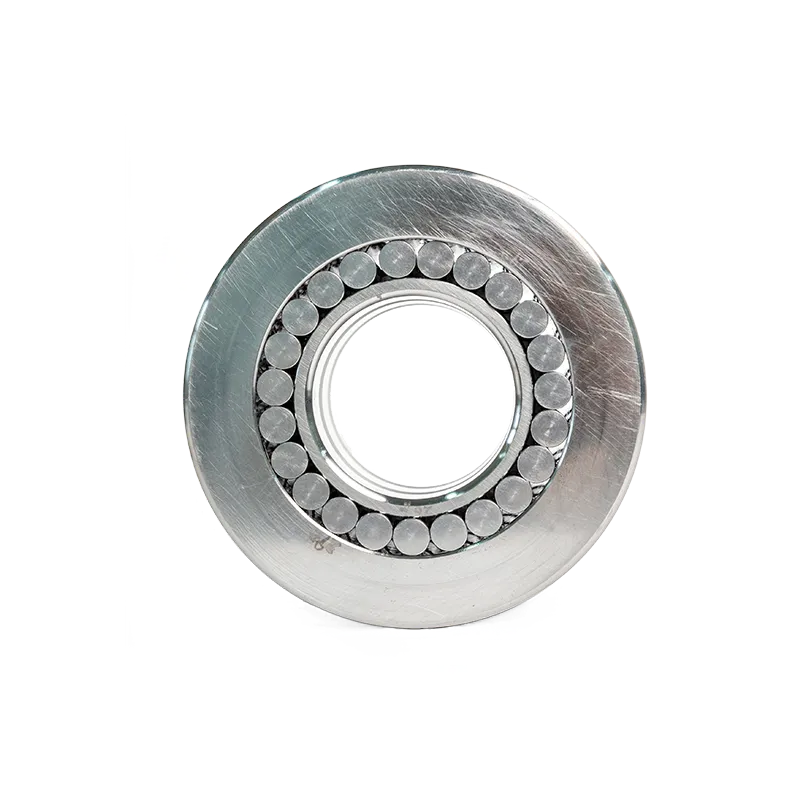

Multi-roll cold rolling mills are widely used for rolling high-precision strips of steel and non-ferrous metals. To prevent the working rolls from shaking, they are supported by intermediate rolls and support shafts. On these support shafts, several Sendzimir Bearings are arranged adjacent to each other separated by support frames. Such an arrangement meets the requirements of load distribution. Depending on the design form, the backing bearing can withstand high radial loads, and can also withstand high radial and axial loads transmitted to the frame through adjacent structures. The backing bearing has strict tolerance requirements and a precision of P4 level. It is used to withstand high loads and can withstand high rolling speeds, up to 1000 m/min depending on the operating conditions. These special properties effectively guarantee the surface quality and flatness of the rolled products. The inner ring of the backing bearing bears point loads and is loosely fitted when installed on the shaft.

With the continuous upgrading of rolling mill equipment and the further improvement of the precision requirements for rolled steel products, Sendzimir rolling mill bearings came into being. The outer diameter of this type of bearing is directly in contact with the intermediate roll and withstands the rolling force while rotating. The outer ring of the bearing has good wear resistance, the inner ring has a sufficiently long rolling fatigue life, the outer ring has the operability of re-grinding, and the outer ring still has good rotation accuracy after re-grinding; the sufficiently soft core has good impact resistance; the sufficiently deep surface hardening layer increases the number of outer diameter repairs while ensuring rigidity; the high-quality material organization ensures high fatigue strength. The difference between the installation wall thickness of all bearings used on one shaft is ≤0.005mm, and the difference between the installation wall thickness of adjacent bearings is ≤0.002mm.

The back up roller bearing have high load capacity; low friction; optimized internal geometry can reduce bearing friction and heat generation; long service life, and the logarithmic curve profile reduces the edge stress at the roller/raceway contact. In addition, the logarithmic curve profile on the outer surface of the bearing outer ring reduces the edge load generated during operation and helps to extend the service life of the bearing. Improve operating reliability The surface treatment of the roller and raceway contact surface is conducive to the formation of fluid dynamic lubrication film. For more effective lubrication, most MONTON backing bearings have lubrication holes, and many bearings have one or more annular lubricating oil grooves on the inner ring for lubrication through the support shaft. The lubricant is transported to the inside of the back up roller bearings through the support shaft, so all backing bearings have lubricating oil holes on the inner ring: some structural forms of bearings also have one or more annular oil grooves on the inner hole. You can contact us for consultation on the number and size of these holes and grooves.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing data and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating a good user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.