|

Bearing Model |

Bearing Size |

Number of Fixing Holes |

||||||||||||||||

|

Inner Ring |

Outer Ring |

|||||||||||||||||

|

d |

D |

H |

H1 |

H2 |

C |

D1 |

D2 |

dn |

dm |

F |

L |

d1 |

d2 |

a |

qty |

d3 |

qty |

|

|

Unit: mm |

mm |

|

mm |

|

||||||||||||||

|

YRTM150 |

150 |

240 |

43 |

29 |

14 |

12 |

214 |

214 |

165 |

225 |

165 |

225 |

7 |

11 |

6.2 |

34 |

7 |

33 |

|

YRTM180 |

180 |

280 |

46 |

32 |

14 |

15 |

244.5 |

244 |

194 |

260 |

194 |

260 |

7 |

11 |

6.2 |

46 |

7 |

45 |

|

YRTM200 |

200 |

300 |

47 |

32 |

15 |

15 |

271.2 |

274 |

215 |

285 |

215 |

285 |

7 |

11 |

6.2 |

46 |

7 |

45 |

|

YRTM260 |

260 |

385 |

55 |

36.5 |

18.5 |

18 |

343.8 |

345 |

280 |

365 |

280 |

365 |

9.3 |

15 |

8.2 |

34 |

9.3 |

33 |

|

YRTM325 |

325 |

450 |

60 |

40 |

20 |

20 |

412.6 |

415 |

342 |

430 |

342 |

430 |

9.3 |

15 |

8.2 |

34 |

9.3 |

33 |

|

YRTM395 |

395 |

525 |

65 |

42.5 |

22.5 |

20 |

485.5 |

486 |

415 |

505 |

415 |

505 |

9.3 |

15 |

8.2 |

46 |

9.3 |

45 |

|

YRTM460 |

460 |

600 |

70 |

46 |

24 |

22 |

557.7 |

560 |

482 |

580 |

482 |

580 |

9.3 |

15 |

8.2 |

46 |

9.3 |

45 |

|

Bearing Model |

Number of Withdrawal Threads |

Angle t×Number |

Screw Tightening Torque MA |

Rated Load |

Weight |

||||

|

Axial |

Radial |

||||||||

|

Dynamic Load Ca |

Static Load Coa |

Dynamic Load Ca |

Static Load Coa |

||||||

|

G |

|

Qty×t |

Nm |

KN |

Kg |

||||

|

qty |

Qty |

||||||||

|

YRTM150 |

M8 |

3 |

36×10° |

14 |

112 |

630 |

56 |

170 |

6.2 |

|

YRTM180 |

M8 |

3 |

48×7.5° |

14 |

118 |

710 |

69.5 |

200 |

7.7 |

|

YRTM200 |

M8 |

3 |

48×7.5° |

14 |

120 |

765 |

81.5 |

220 |

9.7 |

|

YRTM260 |

M12 |

3 |

36×10° |

34 |

160 |

1060 |

93 |

290 |

18.3 |

|

YRTM325 |

M12 |

3 |

36×10° |

34 |

275 |

1930 |

120 |

345 |

25 |

|

YRTM395 |

M12 |

3 |

48×7.5° |

34 |

300 |

2280 |

186 |

655 |

33 |

|

YRTM460 |

M12 |

3 |

48×7.5° |

34 |

355 |

2800 |

200 |

765 |

45 |

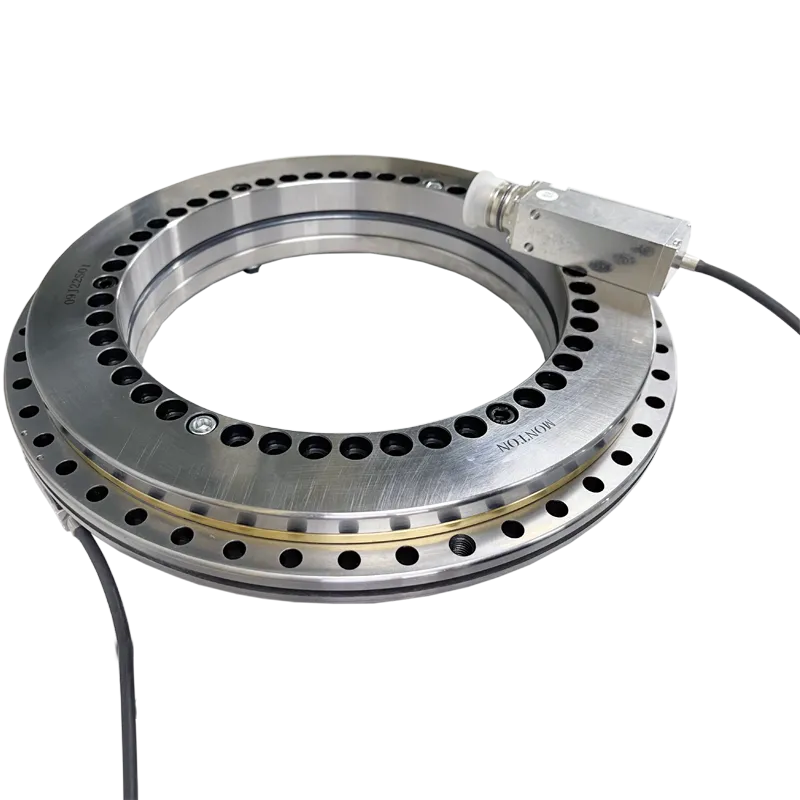

YRTM is a bidirectional thrust cylindrical roller YRT combination bearing with a steel scale installed, which can monitor and adjust the rotation accuracy of the bidirectional thrust cylindrical roller combination bearing in real time to ensure the high-precision operation of the machine. The measurement of angular displacement of turntable bearings with integrated angle measurement system plays a very important role in modern industrial processing, especially in the machine tool industry, which often has high requirements for the rotation angle of the workpiece, which requires accurate measurement and control of angular displacement.

Currently, the more commonly used methods for measuring angular displacement are grating encoders, magnetic grating encoders, etc., which have the advantages of high accuracy (maximum angular resolution is less than or equal to 2 arc seconds), pollution resistance, no electromagnetic influence, and strong environmental adaptability. At the same time, because it is installed on the YRT turntable bearing, the combined bearing has extremely high rotation accuracy and can withstand axial load, radial load and overturning moment at the same time. It is very suitable for high-precision CNC turntables, dividing heads, scientific research experiments and measurements in the machine tool industry. Real-time output signal is an ideal solution for direct drive. The entire steel scale system consists of three parts: steel scale, reading head, and electronic evaluator. The steel scale is a closed steel ring with evenly distributed grids installed on the inner ring of the bearing. The reading head is installed on the outer ring of the bearing, close to the steel scale but not in contact, with a gap of 0.1~0.2 between them.

When the bearing rotates during operation, the steel scale and the reading head make non-contact relative motion, and the data collected by induction are transmitted to the electronic evaluator via a cable. The electronic evaluator then converts the data into square wave or sine wave signals. These signals are input into the CNC system of the machine tool to achieve the measurement and control of angular displacement.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating a good user experience and rich benefits for every customer.

If you have any questions about products and services, please contact the company's service department directly.