|

Bearing Model |

Dimension |

Fixing Holes |

||||||||||||

|

d |

D |

T |

H |

C |

d1 |

dn |

dm |

Inner Ring |

Outer Ring |

|||||

|

Unit: mm |

d0 |

ds |

TS |

Quantity |

dL |

Quantity |

||||||||

|

mm |

mm |

|||||||||||||

|

YRTS200 |

200 |

300 |

45 |

30 |

15 |

274 |

215 |

285 |

7 |

11 |

6.2 |

46 |

7 |

45 |

|

YRTS260 |

260 |

385 |

55 |

36.5 |

18 |

345 |

280 |

365 |

9.3 |

15 |

8.2 |

34 |

9.3 |

33 |

|

YRTS325 |

325 |

450 |

60 |

40 |

20 |

415 |

342 |

430 |

9.3 |

15 |

8.2 |

34 |

9.3 |

33 |

|

YRTS395 |

395 |

525 |

65 |

42.5 |

20 |

486 |

415 |

505 |

9.3 |

15 |

8.2 |

46 |

9.3 |

45 |

|

YRTS460 |

460 |

600 |

70 |

46 |

22 |

560 |

482 |

580 |

9.3 |

15 |

8.2 |

46 |

9.3 |

45 |

|

Bearing Model |

Threaded Withdrawal Hole |

Angle t×number |

Screw Tightening Torque |

Rated Load |

Speed |

Weight |

||||

|

Axial |

Radial |

|||||||||

|

Dynamic Load |

Static Load |

Dynamic Load |

Static Load |

|||||||

|

MA |

Ca |

Coa |

Cr |

Cor |

Grease |

|||||

|

G |

Quantity |

qty×t |

Nm |

KN |

r/min |

Kg |

||||

|

Quantity |

||||||||||

|

YRTS200 |

M8 |

3 |

48×7.5° |

14 |

155 |

840 |

94 |

226 |

1160 |

9.7 |

|

YRTS260 |

M12 |

3 |

36×10° |

34 |

173 |

1050 |

110 |

305 |

910 |

18.3 |

|

YRTS325 |

M12 |

3 |

36×10° |

34 |

191 |

1260 |

109 |

320 |

760 |

25 |

|

YRTS395 |

M12 |

3 |

48×7.5° |

34 |

214 |

1540 |

121 |

390 |

650 |

33 |

|

YRTS460 |

M12 |

3 |

48×7.5° |

34 |

221 |

1690 |

168 |

570 |

560 |

45 |

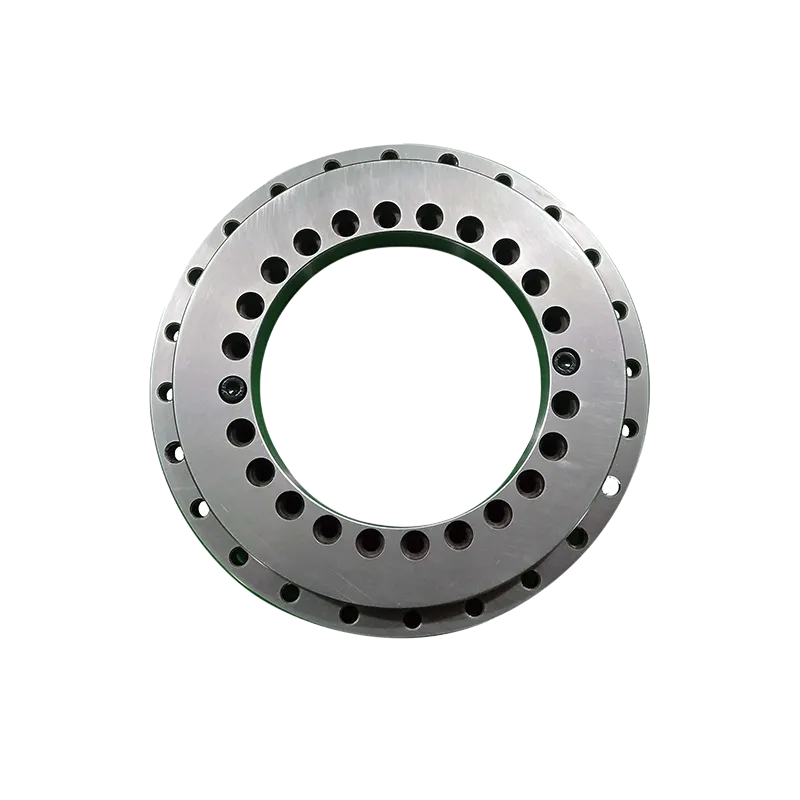

The YRTS type radial bearing has a nylon retainer, and the radial roller adopts a nylon retainer, which makes the YRTS bearing have the characteristics of higher limit speed and very low stable friction torque, so this bearing is suitable for engines with torque. The YRTS high-speed turntable bearing (referred to as YRTS turntable bearing) series has the same appearance and structural dimensions as the YRT series, but the internal structure is different from the YRT series. This determines that the limit speed of the YRTS turntable bearing series is higher than that of the YRT turntable bearing series, and the friction torque is lower and more uniform than that of the YRT turntable bearing series. Therefore, this series can be selected for occasions that require relatively low friction but relatively high speed, such as bearings used for shafts driven by direct drive motors.

Our company has professional sales and technical engineers who are responsible for providing users with precision bearing information and technical consultation, technical services and product technical training on installation and use. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating a good user experience and rich benefits for every customer.

If you have any questions about our products and services, please contact our customer service department directly.