The Type C Deep groove ball bearing is a single row radial ball bearing of conventional design. It is a Conrad-type assembly, which means that it is assembled by eccentric displacement of the inner race within the outer race which permits insertion of about half of a full complement of balls.Although C type bearings are mainly used to withstand radial loads, they can also withstand limited axial (thrust) loads from a certain direction. If axial load is an important factor, using angular contact ball bearings would be more suitable.

View Details

The Type A bearing is also a conventional design. It features a circular pocket separator and a 30° contact angle along with approximately 67% of a full complement of balls.The chief benefit of the Type A bearing is that it provides greater thrust capacity than a Type C or Type X bearing. Because of its counter bored outer race, a Type A bearing has unidirectional thrust capacity. Thus, this bearing should be mounted opposed to another bearing to establish and maintain the contact angle, and to support reversing thrust loads.

View Details

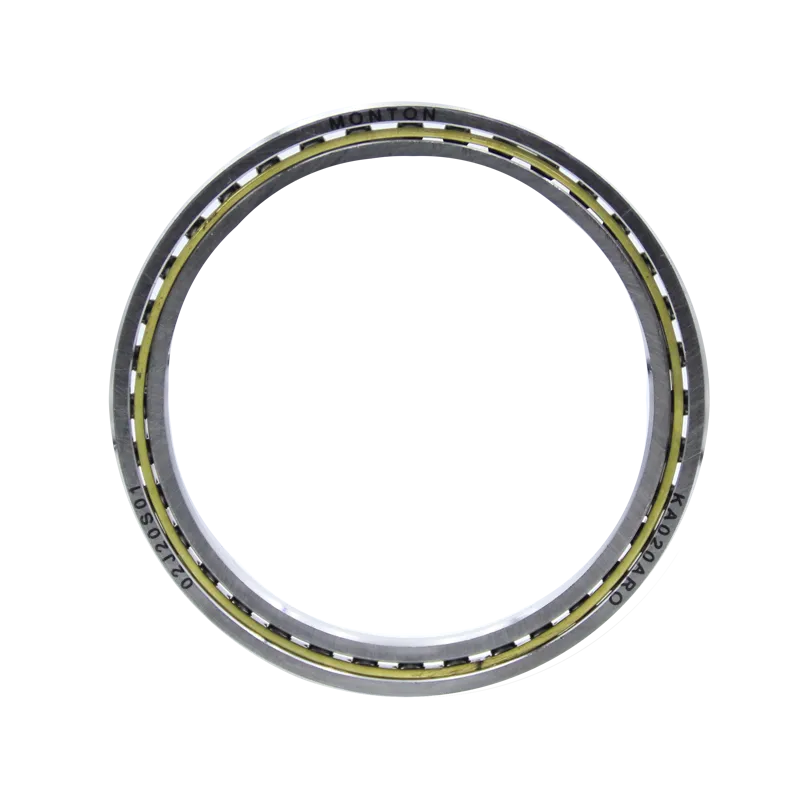

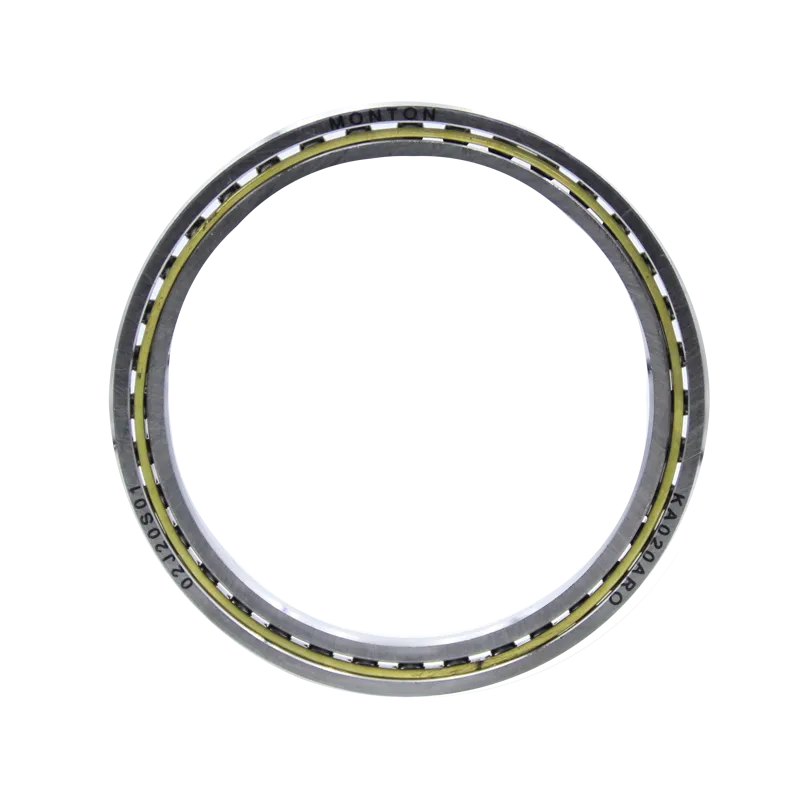

Four Point Contact ball bearing are design to handle both radial and axial load conditions. The four-point contact bearing enables a single bearing to carry three types of loading (radial, axial and moment) simultaneously. This makes it the bearing of choice for many applications since a single four-point contact bearing can often replace two bearings, providing a simplified design.

Type X bearings may also be furnished with an internal diameter preload for those applications requiring greater stiffness or zero free play. This is accomplished by using balls that are larger than the space provided between the raceways. The balls and raceways, therefore, have some elastic deformation in the absence of an external load.

View Details

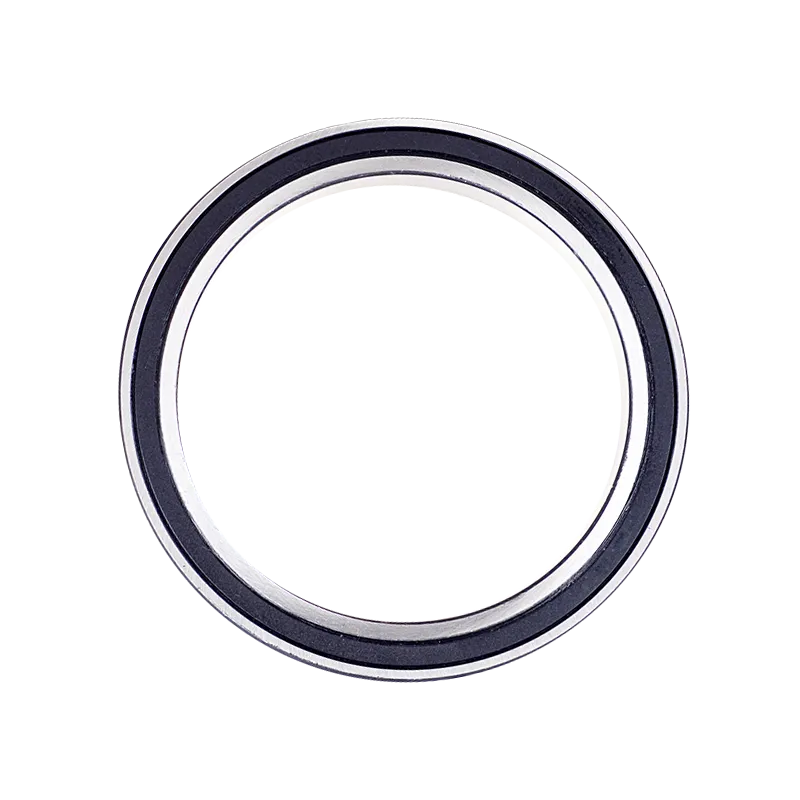

The sealed slim bearings is installed on the outer ring of the bearing and is in direct contact with the inner ring to keep the lubricant inside the bearing from flowing out and prevent foreign substances from entering the bearing. Proper design and installation of bearing seals can help improve the wear resistance of bearings, ensuring their cleanliness and proper lubrication.

View Details

The sealed slim bearings is installed on the outer ring of the bearing and is in direct contact with the inner ring to keep the lubricant inside the bearing from flowing out and prevent foreign substances from entering the bearing. Proper design and installation of bearing seals can help improve the wear resistance of bearings, ensuring their cleanliness and proper lubrication.

View Details

The metric slim Bearing mainly includes specifications with cross-sectional sizes of 8, 13, and 20mm, with inner diameters ranging from 20mm to 360mm. MONTON can provide ceramic ball or integral sealed slim Bearing with cross-section. The metric slim Bearing have three structures: angular contact ball, deep groove ball, and four point ball. The main uses of slim Bearing are stepper motors, medical equipment, office equipment, testing instruments, and speed reducers. Transmission devices, robots, optics. Imaging equipment, rotary encoder.

View Details