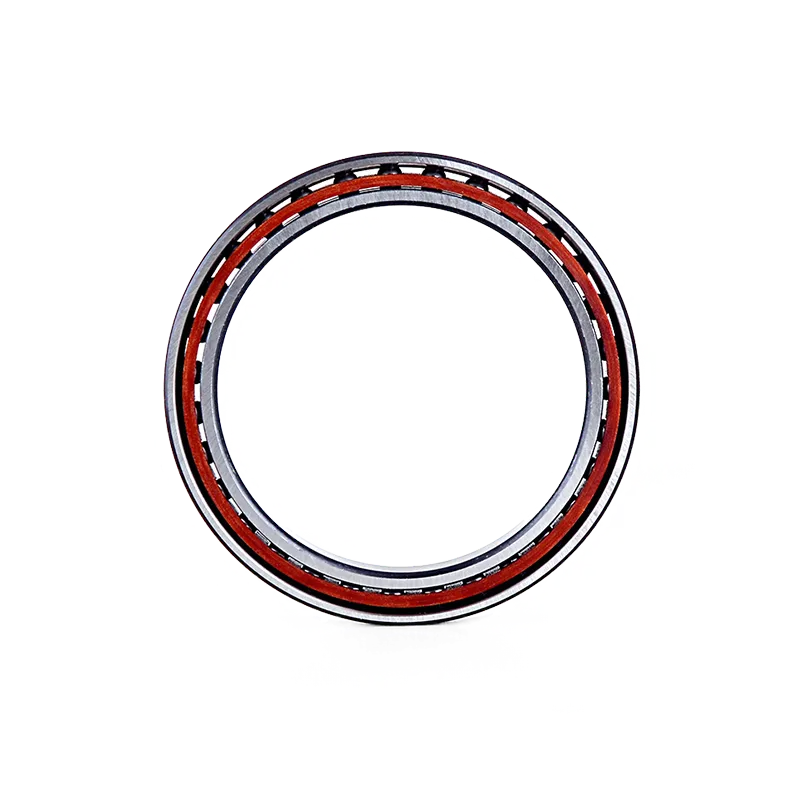

BNR/BER series ultra high speed sealed angular contact ball bearings are add with dust-proof seals, sealing rings on the outer ring to prevent dust, dirt, and other pollutants entering the bearing, effectively reducing the impact of pollutants on bearing performance, extending bearing service life, and reducing maintenance costs. This series is BNR/BER29 and 20 sealing series, with two contact angles of 18 ° (BNR) and 25 ° (BER). The ball materials include steel balls (S), ultra long life bearing rolling elements (E), and ceramic balls (H, X). The cage includes four types: outer ring guided phenolic resin cage (T), outer ring guided PPS resin cage (TSR), and rolling element guided polyamide resin cage (TYN). Due to the sealing structure design, the lubricant inside the bearing can maintain cleanliness for a long time, reduce friction and wear, and improve rotational accuracy. This design is widely used in high-precision mechanical equipment.

View Details

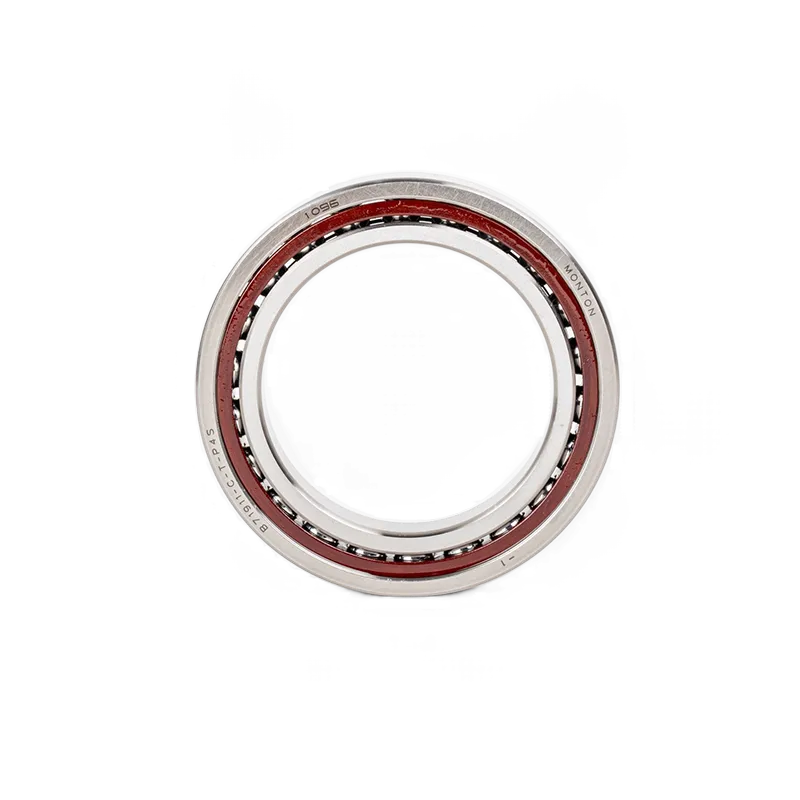

H7XXX series ultra-high speed angular contact ball bearings are products developed for high-speed operation, low temperature rise, and ultra-precision machining. This series mainly includes 70 and 719 series, with contact angles of 15°, 18°, and 25°. The ball materials include steel balls and ceramic balls. The cages include outer ring guided phenolic resin cages, outer ring guided resin cages, and rolling element guided polyamide resin cages. This series achieves high performance characteristics of high rigidity and low heat generation through optimized design.

View Details

High-speed spindle bearings further improve the mechanical and thermodynamic load-bearing capacity of the electric spindle through optimized design, and greatly improve the productivity and competitiveness of customers. High-speed spindle bearings perfectly combine the high-speed performance of the small ball series with the rigidity and load-bearing capacity of the large ball series by selecting the appropriate ball diameter, tightness and internal radial clearance. The small ball bearing series usually used in motor spindlehave a large contact angle, which can effectively prevent thermal limitation during operation. Bearing with 25° contact angle can support higher axial forces than 15° contact angle.

View Details

High-speed motor bearings are mainly used in FANUC servo motors, Siemens servo motors, drilling and tapping machine tools or CNC machining centers, etc. Spindle motors are mostly used in drilling and tapping machine tools or CNC machining centers, and are connected to the rear end of the spindle through a coupling or belt to drive the high-speed rotation of the spindle. The motor is required to have very smooth rotation and reliable acceleration capabilities. The miniaturization of the motor is achieved through optimized structural design, and the selection of bearings is particularly critical. Servo motors require bearings with high precision, high speed, flexible rotation, low noise, low friction, and long life. Our company's bearings of this type greatly meet the application requirements of servo motors.

View Details

In order easy to lubricate effectively, our company provides DLR series straight lubrication angular contact ball bearings with lubrication holes and groove on outer ring. The design have two groove on the outer ring, two lubrication holes in each groove, and two outer grooves with O-rings in the outer ring. The DLR series can directly supply oil from the outer ring to prevent the lubricating oil leaking from the bearing and the bearing seat hole mounting surface to improving the reliability of lubrication. Supply oil through the outer ring oil holes,the spacers will not necessary, and the spindle space can be compactly. In this way, the spindle can running more freely, thereby improving the processing performance.

View Details

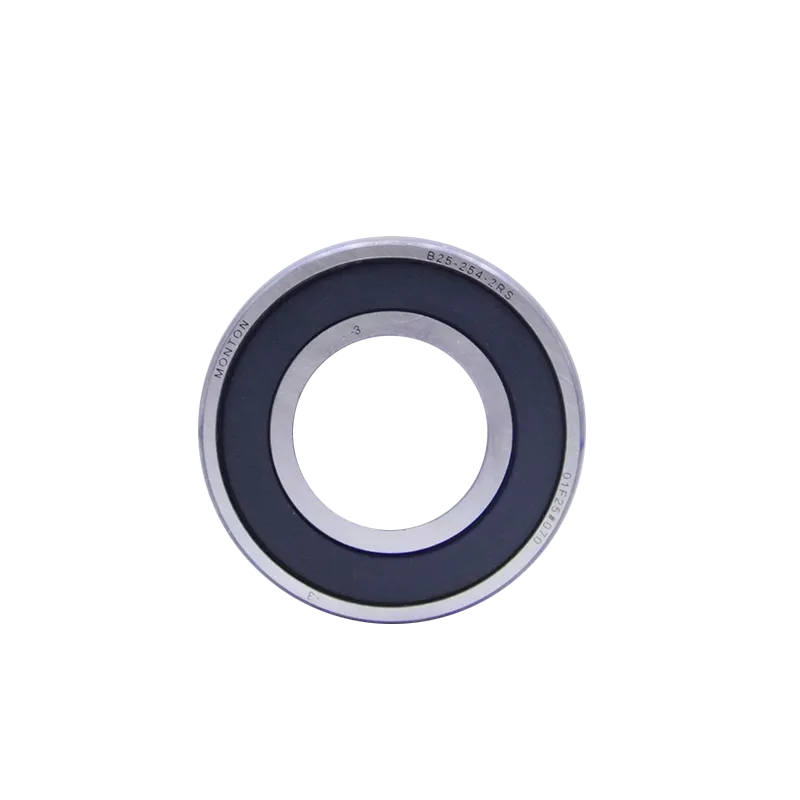

Miniature angular contact ball bearing is a kind of bearing designed for limited space and high-speed rotation requirements. The structure includes inner and outer rings, balls and cages. It adopts angular contact design and has the advantages of small size, high speed, high rigidity and long life. It is widely used in high-speed electric shafts (spindles for wood carving, stone carving, etc.), precision instruments, power tools, aircraft models and other micro-equipment, providing them with reliability and high-performance support. Miniature angular contact ball bearings are also called small bearings or miniature bearings. MONTON miniature angular contact bearings are designed for applications that require compactness, low friction and high speed precision.

View Details