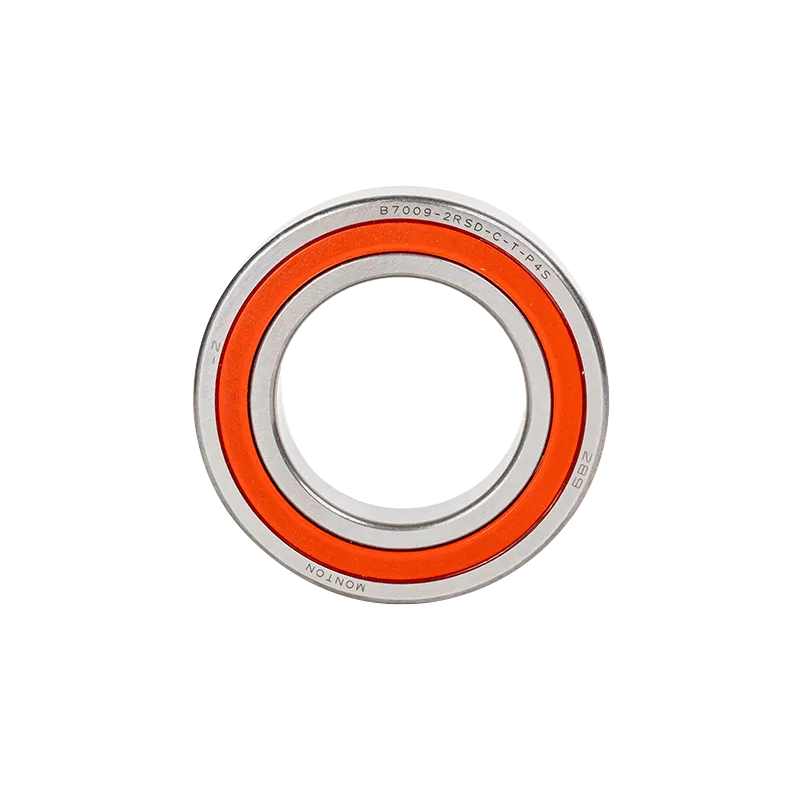

engraving machine mainly uses ultra-high-speed spindle bearings with double-sided sealing rings. The engraving machine requires the bearings must have high speed, wear resistance, low noise, long life, etc. The use of ultra-high-speed spindle bearings with double-sided sealing rings is one of the current mainstream choices. It is mainly used for woodworking engraving machine spindles, stone engraving machine spindles, jade engraving machine spindles, advertising engraving machine spindles, computer engraving machine spindles, CNC engraving machine spindles, etc.

View Details

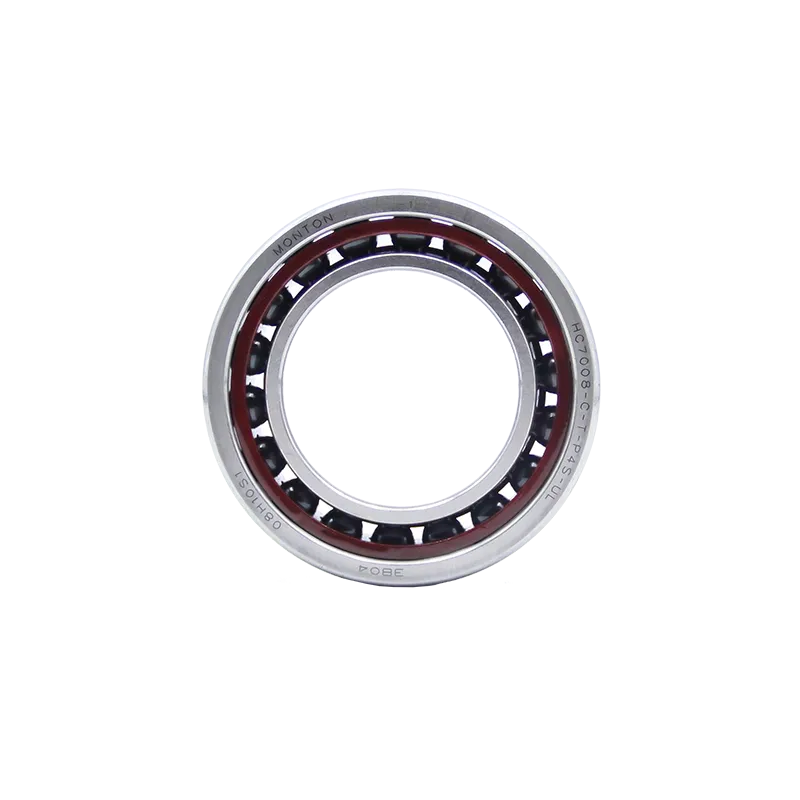

HC70XX series hybrid ceramic ball bearings mainly use small ball design and divided into two types: medium-load HC70 series hybrid ceramic ball spindle bearings and light-load HC719 series hybrid ceramic ball spindle bearings. HC series hybrid ceramic ball bearings do not have seals and can run in high speed. Using ceramic material silicon nitride Si3N4, ceramic balls have the characteristics of high speed, low heat generation, high rigidity and high reliability. Bearings using high-precision ceramic balls can achieve higher precision processing. Ceramic balls are lighter than steel balls. When running at high speeds, they can suppress the increase in internal load caused by centrifugal force compared to steel balls and extend their life.

View Details

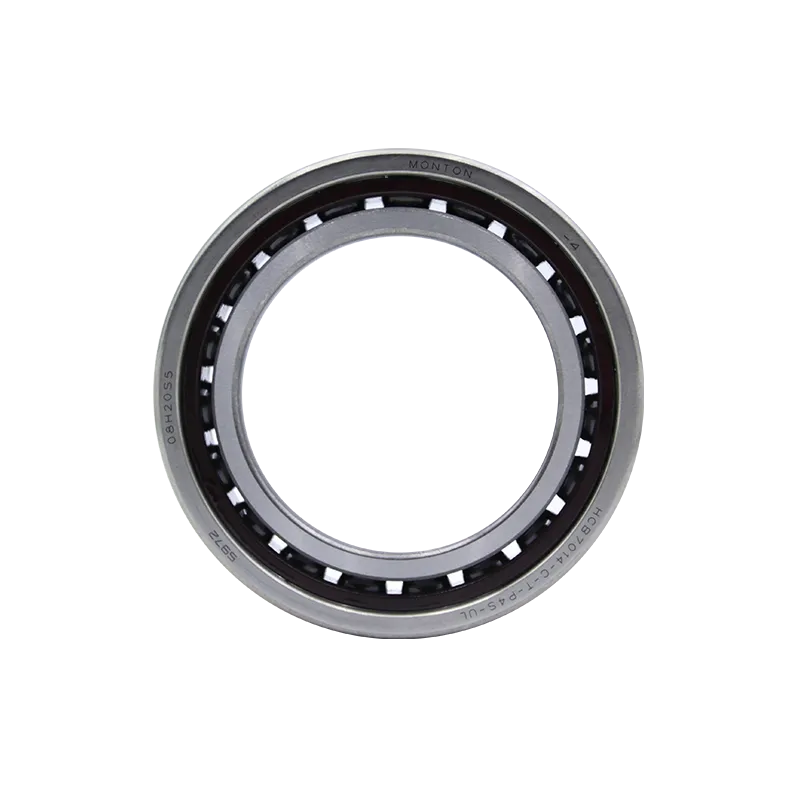

HCB70XX standard series hybrid ceramic ball spindle bearings mainly use standard ceramic ball design, there are three types design: medium-load HCB70 series standard hybrid ceramic ball spindle bearings, light-load HCB719 series standard hybrid ceramic ball spindle bearings and light-load HCB72 series standard hybrid ceramic ball spindle bearings. HCB series hybrid ceramic ball bearings adopt conventional standard ceramic ball bearings without seals on both sides. Using ceramic material silicon nitride Si3N4, ceramic balls have the characteristics of high speed, low heat generation, high rigidity and high reliability. Bearings using high-precision ceramic balls can achieve higher precision processing. Ceramic balls are lighter than steel balls. When running at high speed, compared with steel balls, they can suppress the increase of internal load caused by centrifugal force and extend life.

View Details

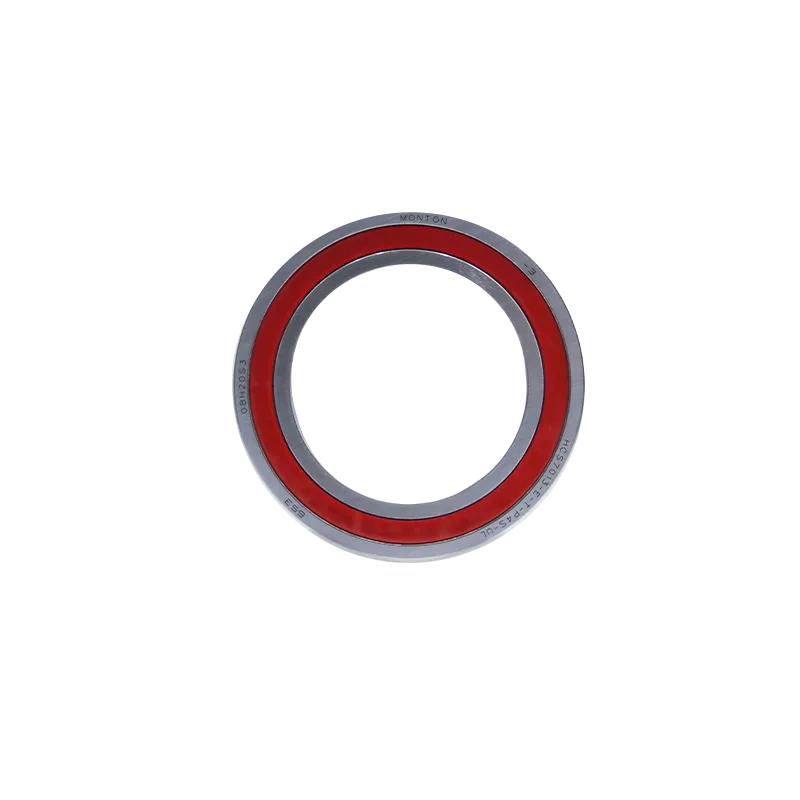

HCS series ceramic ball bearings are high-speed angular contact ball bearings with small balls with seals on both sides. Sealed bearings can provide a low-cost and space-saving solution for many applications. Angular contact ball bearings with non-contact seals are one of the common designs for machine tool spindles. Double-sided sealed bearings are generally lubricated for life and should not be flushed. This type of bearing is filled with an appropriate amount of high-quality grease in a clean environment, and the surface anti-rust oil can be removed when using it. The seal ring can be made of nitrile rubber and fluororubber. This type of material has the characteristics of high temperature resistance and chemical corrosion resistance, and is also very good in anti-aging and anti-oxidation ability, making it the material of choice for seal rings.

View Details

MONTON double direction thrust angular contact ball bearings consist of two single row thrust angular contact ball bearings with back-to-back arrangement and contact angle of 60°. This configuration plus the multi-ball design allows the bearing to withstand high axial loads in both directions and provide high system rigidity. The two bearings are separated. When the shaft rings are pressed together, a preload within a preset range can be obtained, so it is often used in the bidirectional positioning of machine tool spindles.

View Details