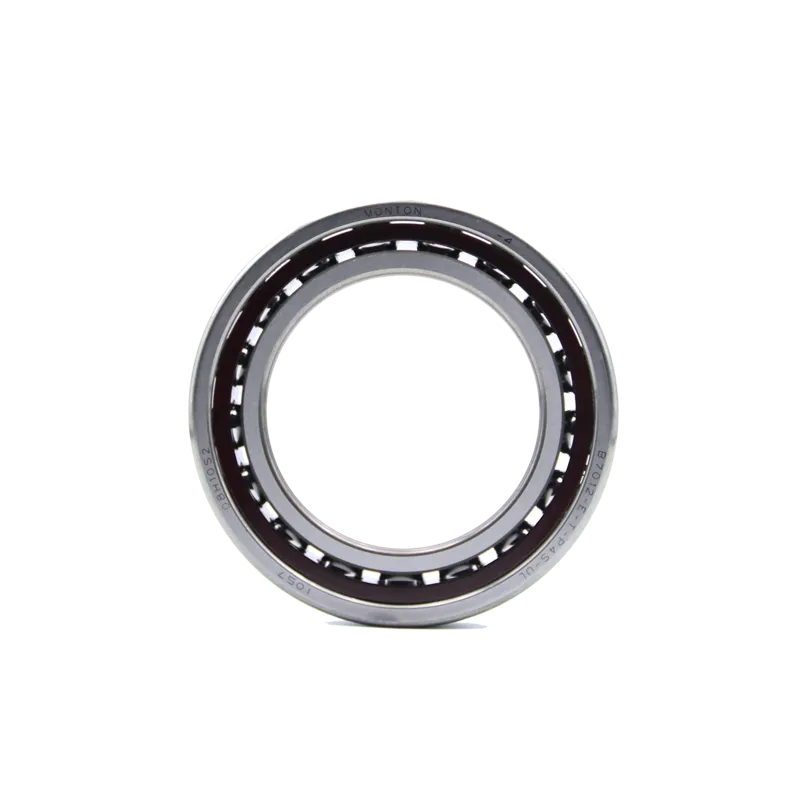

MONTON B70XX light series angular contact ball bearings are inseparable design, produce size range inner diameters from 6 to360mm. The bearings have a variety of designs and structure, we can provide to customer with wide range choices, so that each machine tool spindle can match one suitable precision bearings. MONTON provides contact angles of 15°, 18°, 25°, 30° and 40°. The contact angle of the bearing increases, the axial load capacity increases. At the same time, MONTON can also provide high load,high rigidity and high speed bearings. The rolling elements include steel balls and hybrid ceramic balls for customers to choose. There are open and sealed bearings which can provide best support for customers.

View Details

MONTON B72XX robust Series angular contact ball bearings size from10mm-400 mm. B72 series bearings have a large cross-section height and suitable for heavy-load, low-speed application. MONTON provides bearings with contact angles of 15°, 18°, 25°, 30° and 40°. The contact angle increases, the axial load capacity increases, and the speed will decreases. At the same time, MONTON can also provide high-load and high-speed design. The rolling elements include steel balls and hybrid ceramic balls for customers to choose from. There are open and sealed bearings to provide better support for customers.

View Details

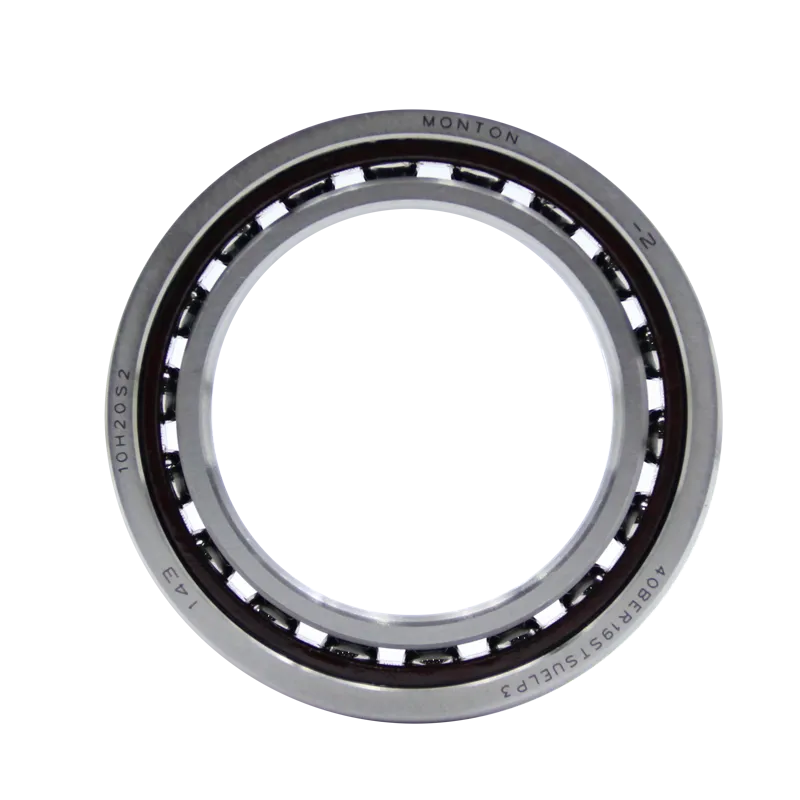

MONTON B718XX ultra light series angular contact ball bearings size from10mm to 300 mm. The B718XX series bearings are mainly used in applications for small cross-sections are required as design parameters. They are high-speed bearings with compact cross-section design. MONTON provides light series bearings with contact angles of 15°, 20° and 25°. Ultra-light series angular contact ball bearings can use small or large balls, steel balls or ceramic balls, open and sealed bearings, DLR designed bearings, and ultra-light series angular contact ball bearings with smaller contact fit and small steel balls. Therefore, it can adapt to very high speeds, and the load capacity of the bearing is lower than that of the 70/72 series.

View Details

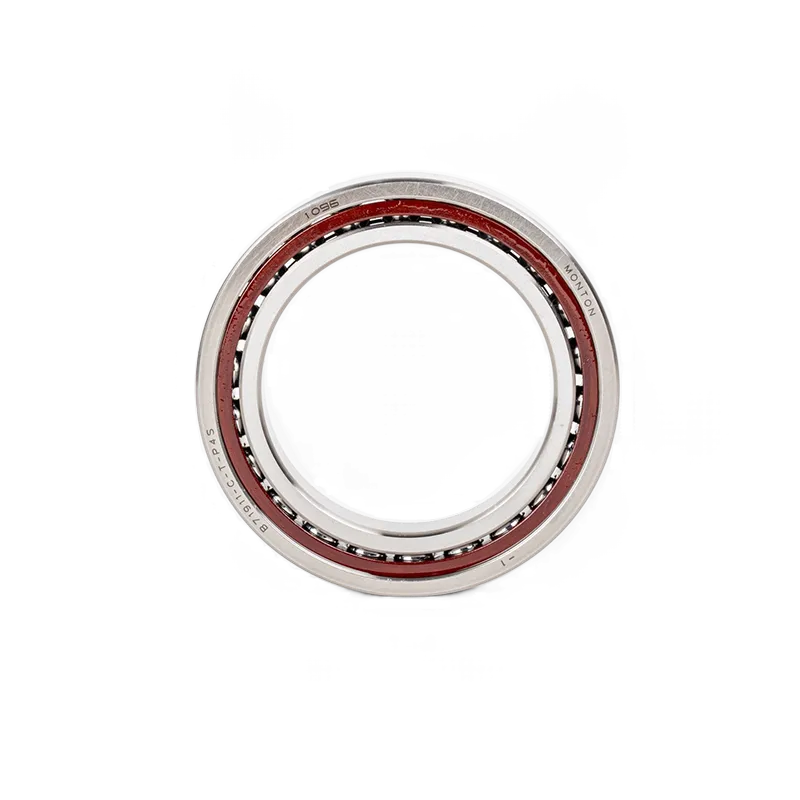

MONTON B719XX extremely light Series Angular Contact Ball Bearings diameter from 10-670mm . B719XX extremely light Series Angular Contact Ball Bearings are mainly used in applications where available space is limited. They are high-speed bearings with a compact cross-section design. MONTON offers products with light series contact angles of 15°, 20° and 25°. Ultra-light series angular contact ball bearings can use small or large balls, steel balls or ceramic balls, open and sealed bearings, DLR designed bearings, and ultra-light series angular contact ball bearings with smaller contact fit and small steel balls. Therefore, it can adapt to very high speeds, and the same inner diamter bearing load capacity of the bearing is lower than the 70/72 series.

View Details

BAR/BTR High-Speed Angular Contact Thrust Ball Bearings are high-performance products developed for high-speed and high-rigidity applications such as lathe spindles. This series has two contact angles: 30° (BAR) and 40° (BTR), and three ball materials: steel balls (S), ultra-long-life bearing rolling elements (E), and ceramic balls (H). Bearings with a 30° contact angle can withstand faster speeds, while bearings with a 40° contact angle are more suitable for applications that require higher axial rigidity. BAR and BTR are designed with special width dimensions and can be used interchangeably with 2344 series bidirectional thrust angular contact bearings. They can meet the needs of low heat, high speed, and high rigidity applications.

View Details

BNR BER Ultra High-Speed Angular Contact Ball Bearings are a high-performance series developed for high-speed operation, low temperature rising, and ultra-precision processing. This series has separate 19, 10, and sealed 29, 20 series, with contact angles of 18° (BNR) and 25° (BER), ball materials of steel balls (S), ultra-long life bearing rolling elements (E), and ceramic balls (H, X), and cages of outer ring guided phenolic resin cages (T), outer ring guided PPS resin cages (TSR), and rolling element guided polyamide resin cages (TYN). This series achieves high-performance characteristics of high rigidity and low heat generation through optimized design.

View Details